Colored microcapsule concrete and preparation method thereof

A microcapsule and concrete technology, applied in the field of building materials, can solve the problems of poor adhesion between concrete and dyes, fading of concrete, insufficient strength of concrete, etc., and achieve the effect of novel colorimetric characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The preparation method of colored microcapsule concrete comprises the following steps:

[0034] Step 1: Process aggregates, cement, microcapsule composite dyes, polycarboxylate superplasticizers, fly ash, mineral powder and other components into required sizes and pre-homogenize them;

[0035] Step 2: Carry out continuous batching according to weight ratio;

[0036] Step 3: Put the prepared aggregate, cement, fly ash, mineral powder, etc. into the mixer and stir for 1-2 minutes;

[0037] Step 4: Add microcapsule composite dye and stir for 2-3 minutes;

[0038] Step 5: Add water and stir for 1-2 minutes;

[0039] Step 6: Finally, add polycarboxylate water reducer and stir for 2-3 minutes to obtain the colored microcapsule concrete.

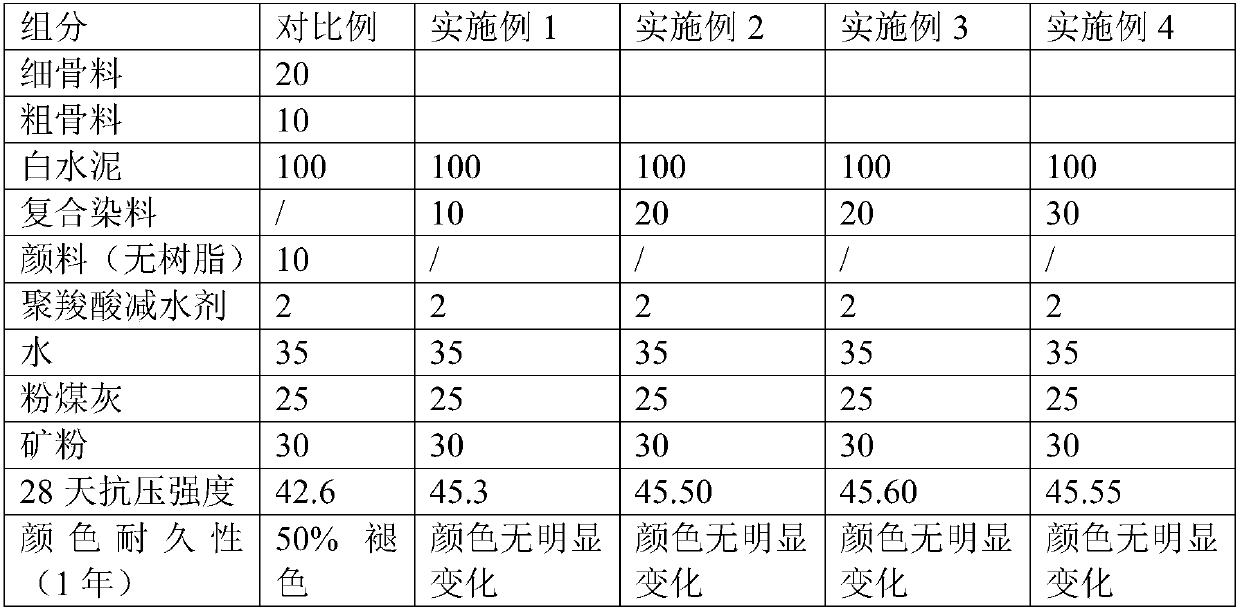

[0040] The difference of each embodiment is only the mass parts of each component is different, and the mass parts of each component in Comparative Examples and Examples 1-4 are shown in Table 2 below.

[0041] Table 2:

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com