Manufacturing method and mold of plastic reduction box shell, plastic reduction box of waterwheel aerator and waterwheel aerator

A water wheel aerator and manufacturing method technology, applied in transmission boxes, mechanical equipment, components with teeth, etc., can solve the problems of oil leakage at the joint of the two half-shells, demoulding, complex processes, etc., to reduce the process , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

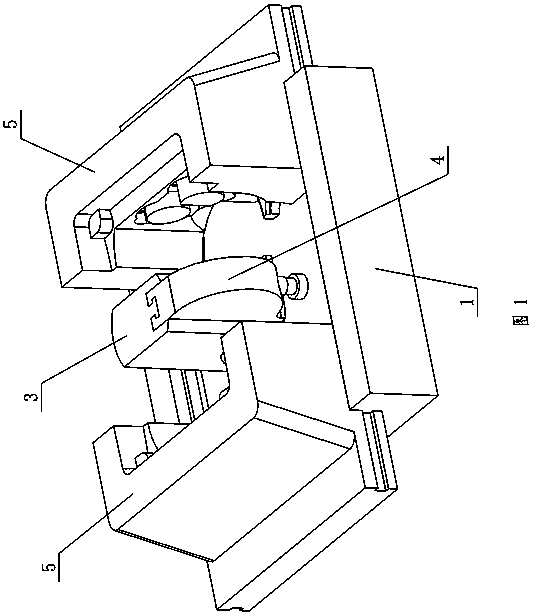

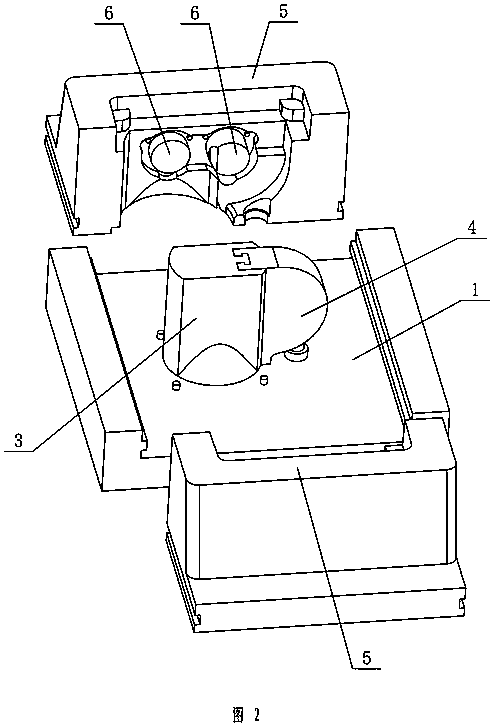

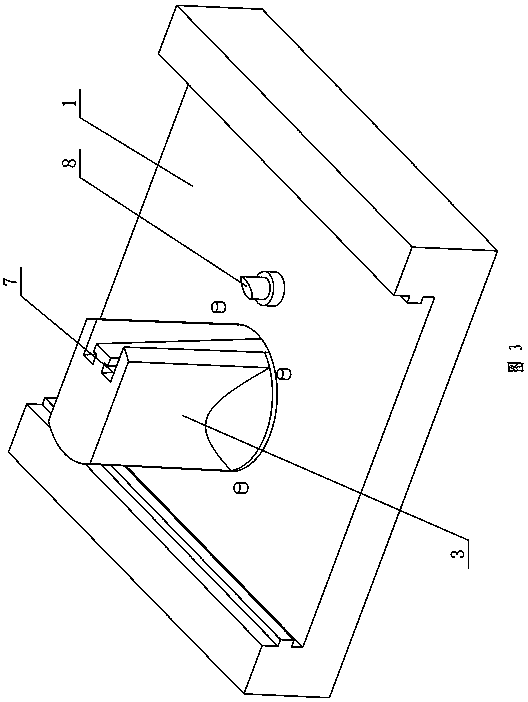

[0034] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 -16:

[0035] A method for manufacturing a plastic gearbox shell of a waterwheel aerator mainly includes injection molding equipment and a mould. The mold is mainly composed of a core and no less than two openable and closable cavity blocks 5 . The core is divided into a main core 3 and a secondary core 4 , and the secondary core 4 is arranged on the main core 3 . After the mold is injected with plastic on the injection molding equipment, the mold is opened and the workpiece is separated from the main core 3, and the auxiliary core 4 remains in the workpiece, that is, the auxiliary core 4 remains in the injection-molded plastic gearbox shell 12, and the auxiliary mold Core 4 is taken out from the vacancy left after breaking away from main core 3, and the method for taking out secondary core 4 includes manually taking out or manipulator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com