Thermosensitive medical image recording material

An image recording and heat-sensitive technology, applied in temperature recording method, copying/marking method, printing, etc., can solve the problems of high resolution, consumption of precious metals, pollution of the environment, etc., and achieve the effect of high resolution and fast development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

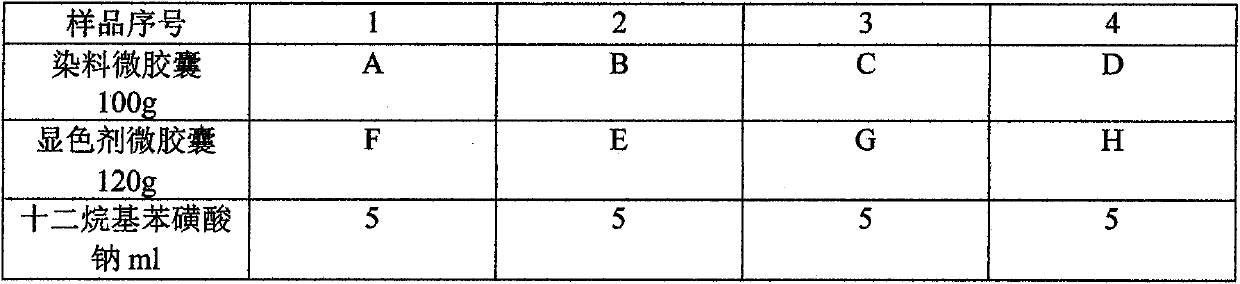

Embodiment 1

[0026] The preparation of embodiment 1 dye precursor microcapsule A

[0027] Put 8g ODB-2, 5ga-methylnaphthalene, and 30g ETAC into the same beaker, stir, and heat in an automatic constant temperature electric heating mantle to dissolve ODB-2 in the high boiling point solvent α-methylnaphthalene and low boiling point solvent In the mixed solvent of ETAC, take it out and cool it to room temperature, ODB-2 cannot be precipitated; put 20ml of D-110 into it, stir to get the oil phase mixture.

[0028] Measure 135ml of PVA-224 aqueous solution with a concentration of 3% and put it into a shear tank, add 20ml of surfactant, and the water phase is ready

[0029] The water phase was sheared at a high speed by a high-speed hardening shear at a speed of 13,000 rpm, and then the oil phase was added to the water phase, emulsified and dispersed for 10 minutes to obtain an oil-in-water emulsion. Add 300 ml of deionized water and 8 grams of tetraethylenepentamine to the oil emulsion dispers...

Embodiment 2

[0030] The preparation of embodiment 2 dye precursor microcapsules B

[0031] Put 8g ODB-2, 5ga-methylnaphthalene, and 30g ETAC into the same beaker, stir, and heat in an automatic constant temperature electric heating mantle to dissolve ODB-2 in the high boiling point solvent α-methylnaphthalene and low boiling point solvent In the mixed solvent of ETAC, take it out and cool it to room temperature, ODB-2 cannot be precipitated; put 20ml of D-110 into it, stir to get the oil phase mixture.

[0032] Measure 135ml of PVA-224 aqueous solution with a concentration of 3% and put it into a shear tank, add 10ml of surfactant, and the water phase is ready

[0033] The water phase was sheared at a high speed by a high-speed solidifying shear at a speed of 7000 rpm, and then the oil phase was added to the water phase, emulsified and dispersed for 10 minutes to obtain an oil-in-water emulsion. In the oil emulsion dispersion, add deionized water 300ml, tetraethylenepentamine 8 grams, the...

Embodiment 3

[0034] The preparation of embodiment 3 dye precursor microcapsules C

[0035] Put 8g ODB-2, 5ga-methylnaphthalene, and 30g ETAC into the same beaker, stir, and heat in an automatic constant temperature electric heating mantle to dissolve ODB-2 in the high boiling point solvent α-methylnaphthalene and low boiling point solvent In the mixed solvent of ETAC, take it out and cool it to room temperature, ODB-2 cannot be precipitated; put 20ml of D-110 into it, stir to get the oil phase mixture.

[0036] Measure 135ml of PVA-224 aqueous solution with a concentration of 3% and put it into a shear tank, add 20ml of surfactant, and the water phase is ready

[0037] The water phase was sheared at a high speed by a high-speed hardening shear at a speed of 14,000 rpm, and then the oil phase was added to the water phase, emulsified and dispersed for 10 minutes to obtain an oil-in-water emulsion. Add 300 ml of deionized water and 8 grams of tetraethylenepentamine to the oil emulsion dispersi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com