Method for extracting characteristic line of repair model of tooth preparation body

A restoration model and extraction method technology, applied in the field of denture restoration, can solve problems such as insufficient stability and inability to achieve accurate extraction of tooth preparation feature lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

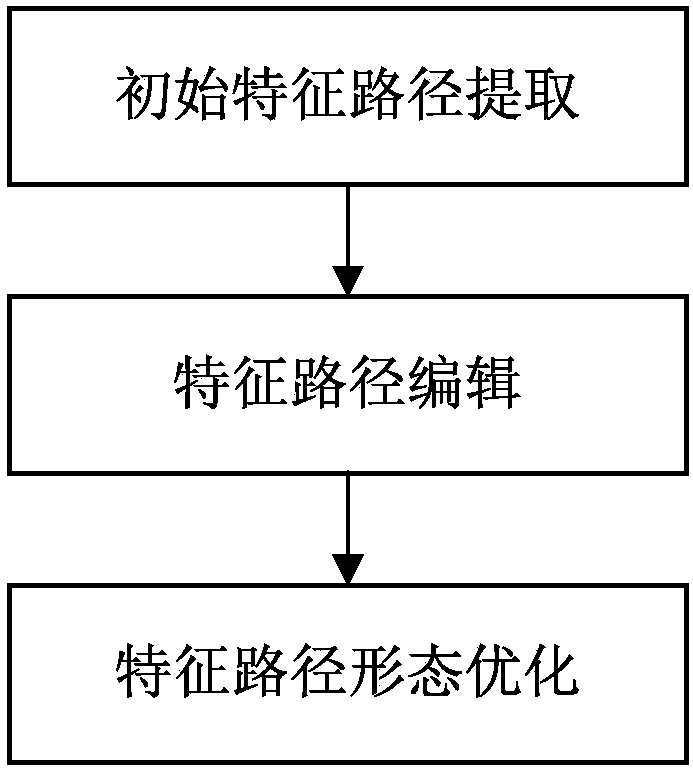

[0122] Aiming at the shortcomings of the existing feature line extraction technology, the present invention proposes a heuristic tooth preparation model feature line extraction method for dentists, which can realize various common preparation models only by manually selecting 3 to 5 feature points The extraction of feature lines, and the extraction of feature lines can still be realized in the local feature interference area, and a new shape optimization algorithm is adopted to make the shape of the extracted feature lines more accurate and smooth and natural.

[0123] Such as figure 1 As shown, the tooth preparation restoration model feature line extraction method of the present invention comprises the following steps:

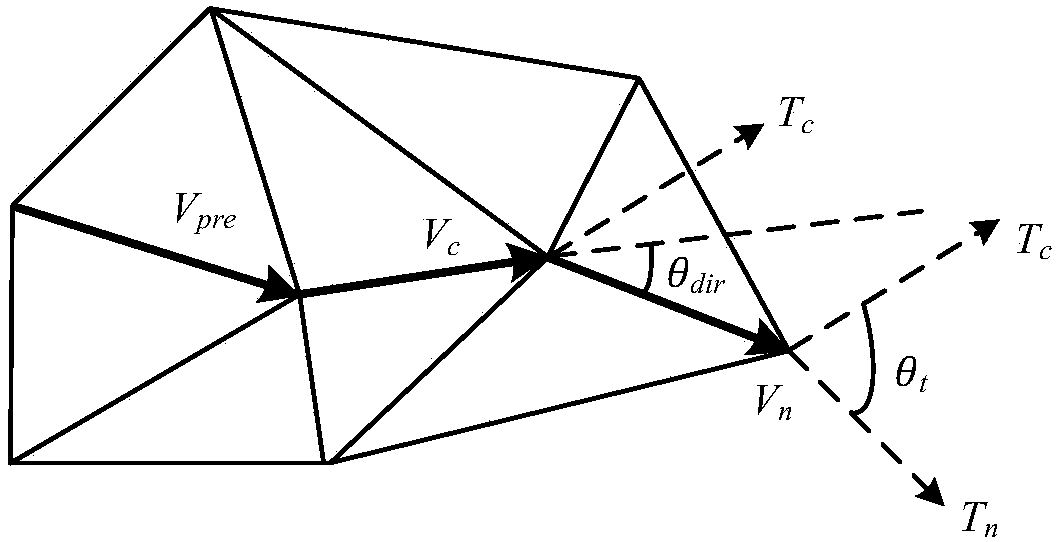

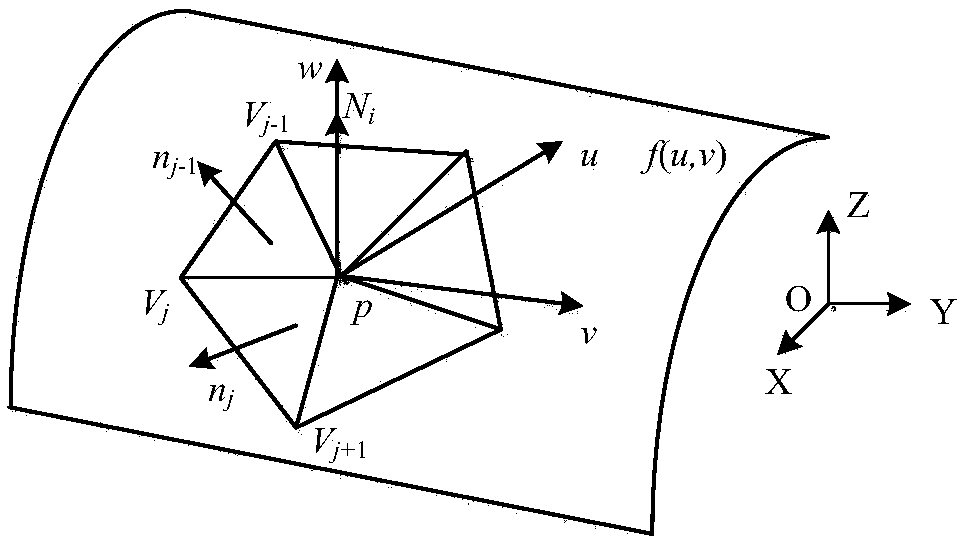

[0124] Step 1. Interactively pick key feature points in the feature area of the neck edge or hole edge of the prepared body, and then extract the initial feature path between two adjacent key feature points.

[0125] The path nodes between any two adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com