Millimeter-wave fin-line switching feed circuit

A feeding circuit and millimeter wave technology, applied in the millimeter wave field, can solve problems such as microwave signal leakage and impact indicators, and achieve the effect of simple design and excellent circuit performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

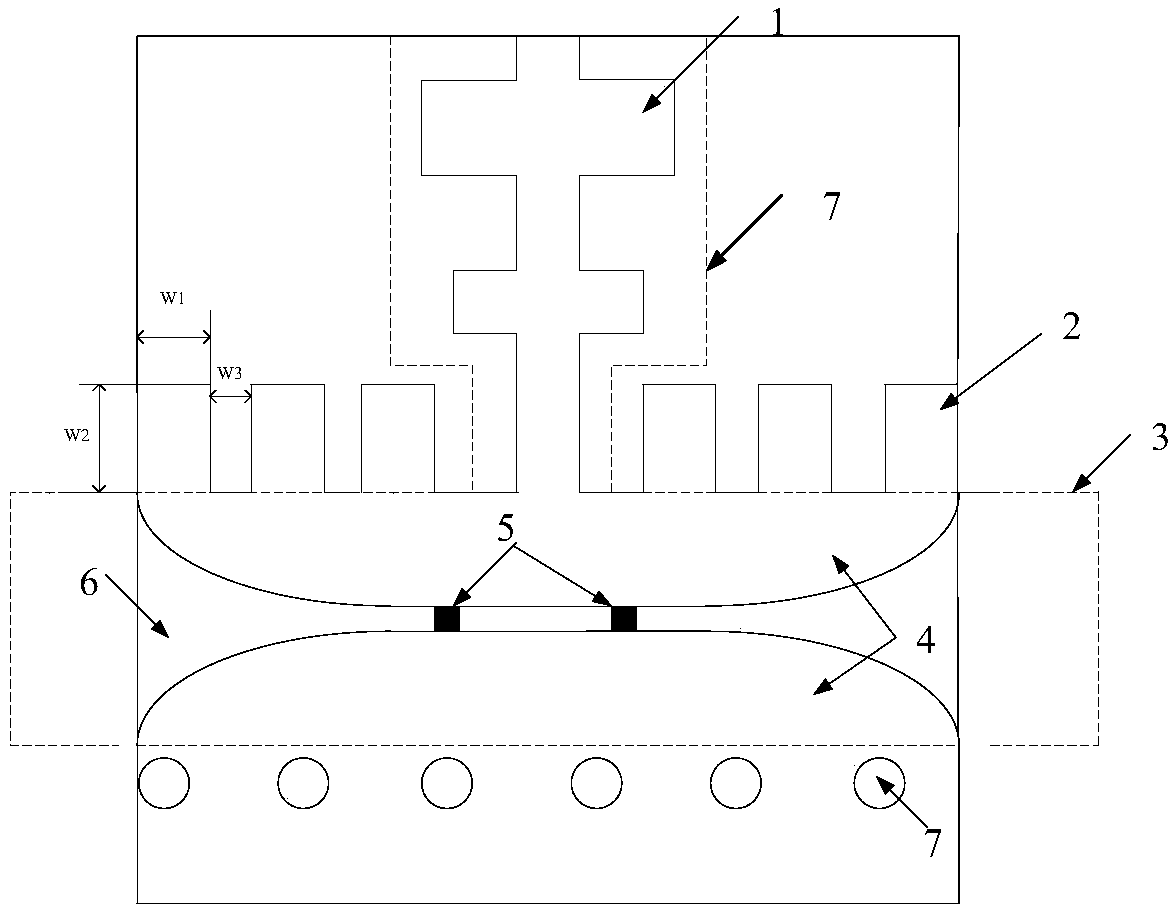

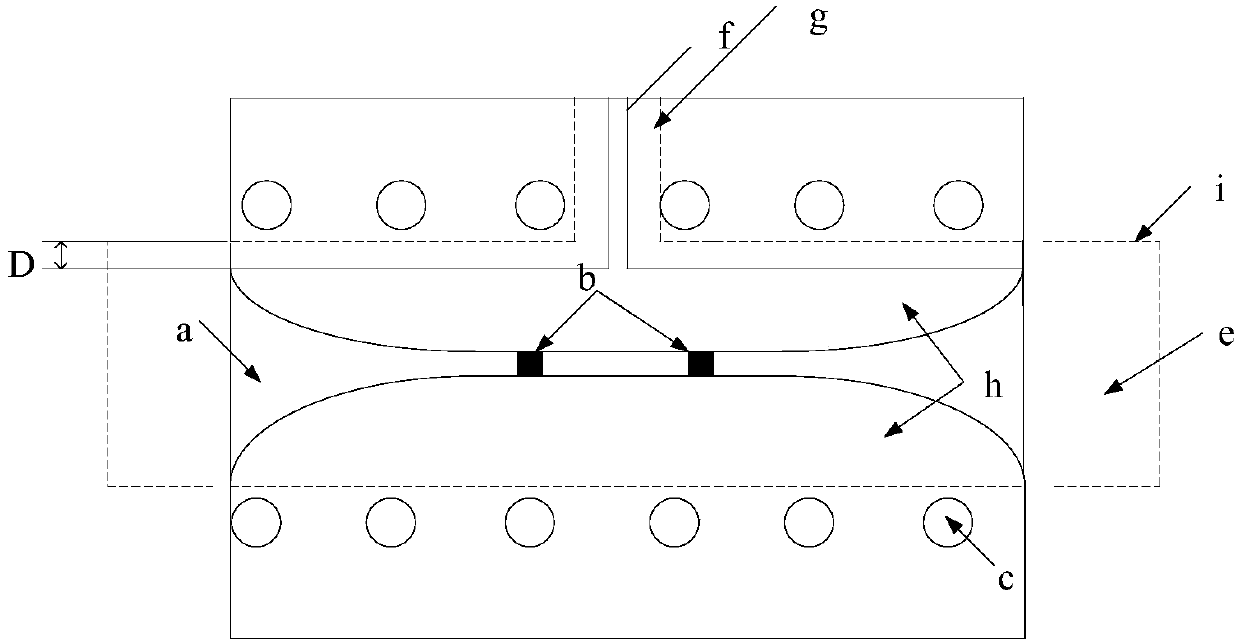

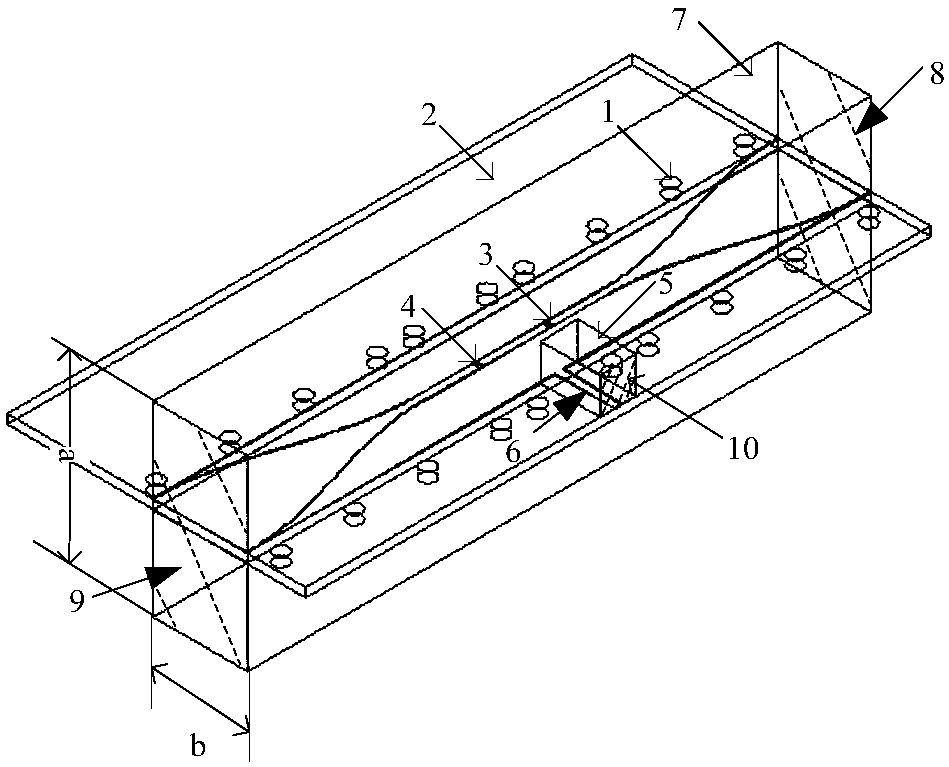

[0018] figure 1 The traditional millimeter-wave fin-line switch feeding scheme is shown. The printed circuit board substrate circuit 4 is placed between the upper and lower half waveguides, and the waveguide is divided into two. Among them, 1 is a low-pass filter, and 2 is a sawtooth branch. 3 is a waveguide cavity, 4 is a fin circuit made of copper foil, 5 is a PIN diode, 6 is a printed board substrate, 7 and a circle with the same radius as 7 are metal vias. The traditional millimeter-wave fin-line switch feeding scheme is a mature scheme, and its structure and principle will not be repeated. The main invention points of the present invention are also different from the traditional scheme: first, replace the jagged branches with Uniformly metallized vias, such as figure 2 As shown in c. The via hole placement principle is the same as that of the non-feeder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com