PCB dismounting equipment and method

A PCB board and equipment technology, which is applied in the field of PCB board removal equipment, can solve the problems of not being able to keep the device and the PCB board separated, the PAD on the PCB board falling off, and the heat not covering all the pins, etc., to achieve simple structure, convenient disassembly, The effect that usage is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

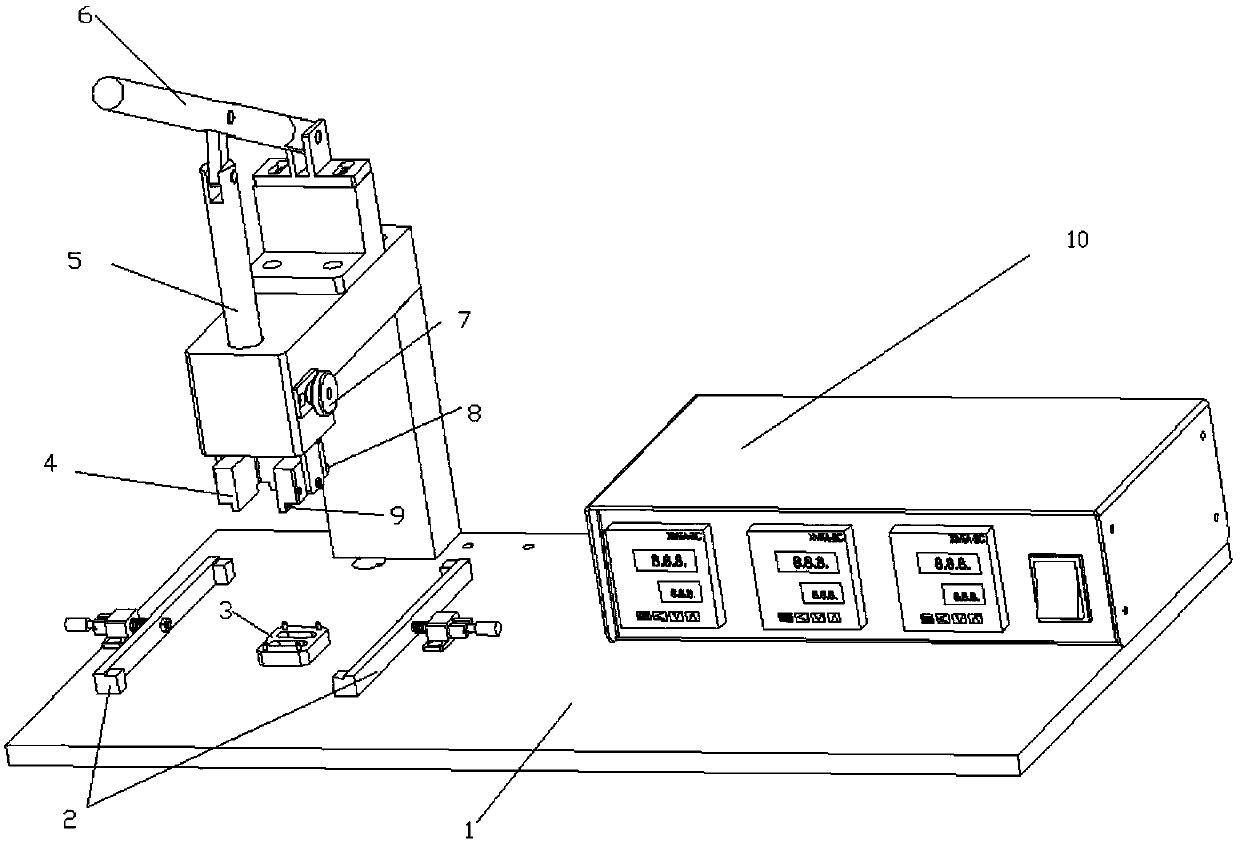

[0040] Such as figure 1 As shown, a kind of PCB board dismantling equipment of the present invention comprises the PCB fixing support structure 2 for supporting and positioning the PCB board, the device positioning support structure 3 for supporting and positioning the butterfly device on the PCB board, The heating block 4 used to heat the pins around the butterfly device on the PCB, the mechanical structure used to drive the heating block 4 to move up and down, and the heating temperature control system 10 used to heat the heating block 4 and keep the temperature stable.

[0041] Such as figure 1 As shown, it also includes a stage 1 for placing a PCB fixed support structure 2 , a device positioning support structure 3 , a mechanical structure that drives the heating block 4 to move up and down, and a heating temperature control system 10 .

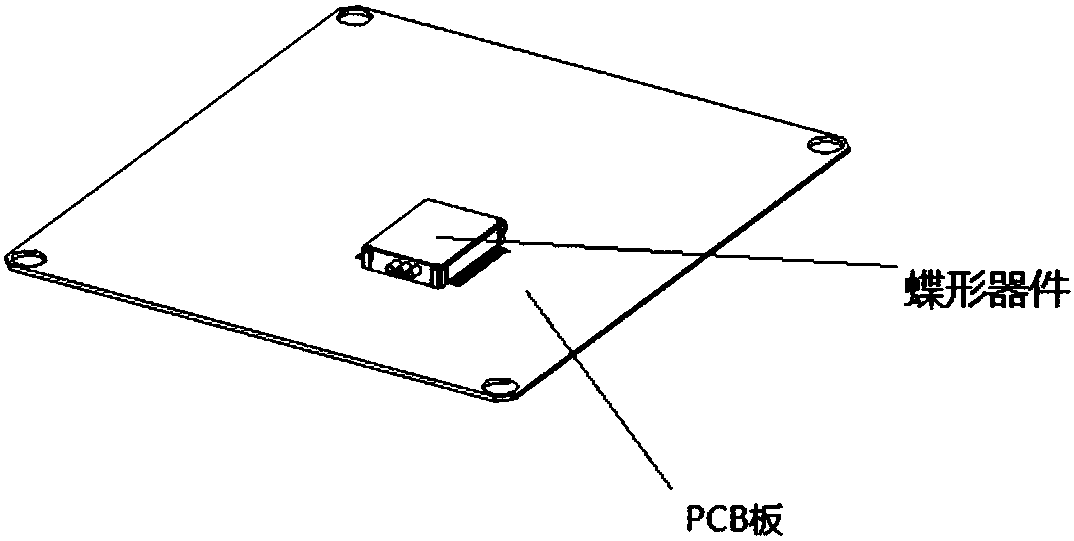

[0042] figure 2 It is a PCB board of a butterfly device to be disassembled provided by an embodiment of the present invention, such a...

Embodiment 2

[0050] This embodiment is a method embodiment, and belongs to the same technical concept as the above-mentioned embodiment 1. Please refer to the above-mentioned embodiment 1 for the content not described in detail in this embodiment.

[0051] A kind of dismantling method of the PCB board dismantling equipment that adopts above-mentioned butterfly device of the present invention, concrete operation steps are as follows:

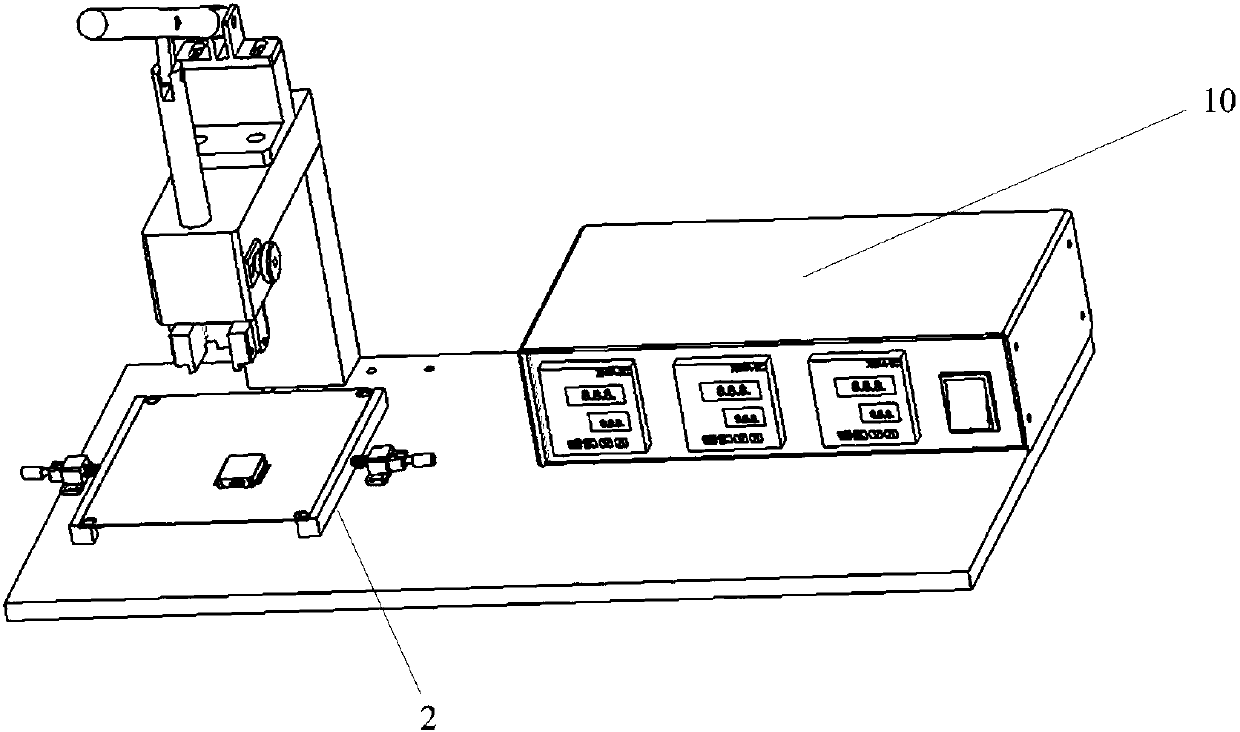

[0052] Step 1. Open figure 1 The movement rod positioning structure 7 in the middle, the heating block 4 is lifted to the highest position by moving the handle 6 up and down, and then the movement rod positioning structure 7 is locked, and the heating block 4 remains still;

[0053] Step 2. Unscrew figure 2 The four fixing screws fixing the butterfly device on the back of the PCB board to be removed;

[0054] Step 3. If image 3 As shown, the PCB board is placed on the PCB fixed support structure 2 of the stage 1, and the top column of the device position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com