Ultrasound-assisted heterogeneous material friction stirring lap-joint device and lap-joint method

A friction stir, heterogeneous material technology, used in welding/welding/cutting items, welding equipment, non-electric welding equipment, etc., can solve problems such as insufficient plastic flow, internal defects, hook defects, etc. The effect of eliminating groove defects and improving joint structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

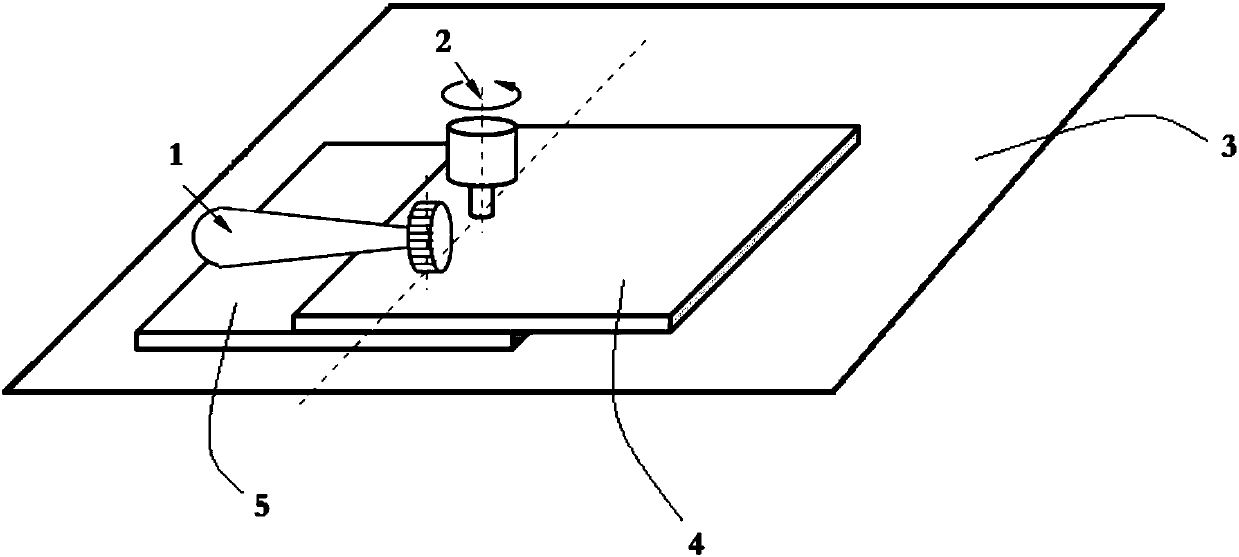

[0027] Embodiment 1: as figure 1 As shown, an ultrasonic-assisted friction stir welding device for dissimilar materials in this embodiment includes an ultrasonic vibration device 1, a friction stir welding tool 2 and a movable worktable 3; an upper lap plate 4 and a lower lap plate 5 are formed The workpiece to be welded is fixed on the movable workbench 3 by a clamp, the friction stir welding tool 2 is placed above the overlapping area of the workpiece to be welded, and the stirring needle of the friction stir welding tool 2 penetrates into the overlapping area, so that The rolling head of the ultrasonic vibrating device 1 acts on the overlapping area; the distance between the ultrasonic action center position of the rolling head of the ultrasonic vibrating device 1 and the welding center position of the stirring needle of the friction stir welding tool is 1000mm; the ultrasonic vibrating device 1 There is no direct rigid connection with the friction stir welding tool; the ...

Embodiment 2

[0028] Embodiment 2: This embodiment relies on the lapping device described in Embodiment 1 to realize, and this embodiment is realized through the following steps:

[0029] Step 1: Start the ultrasonic vibration device, and apply ultrasound to the starting position of the predetermined route;

[0030] Step 2: Start the friction stir welding tool, and insert the stirring needle at the starting position of the expected welding route;

[0031] Step 3: After the insertion is completed, the workbench runs along the established track to realize continuous welding;

[0032] Step 4: After the predetermined trajectory is completed, the stirring needle and the welding end position are separated from the weld;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com