Device and method for improving laser drilling quality of plates

A laser drilling and quality technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of residual spatter at the exit of the hole, more spatter at the orifice, micro-cracks in the orifice, etc. The effect of punch quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Further description below in conjunction with accompanying drawings.

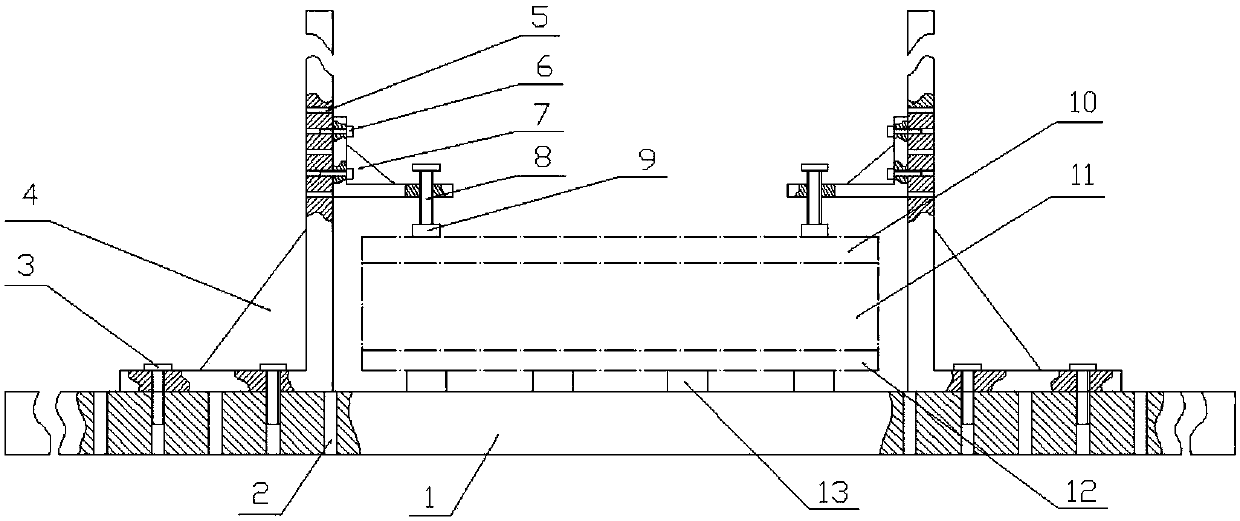

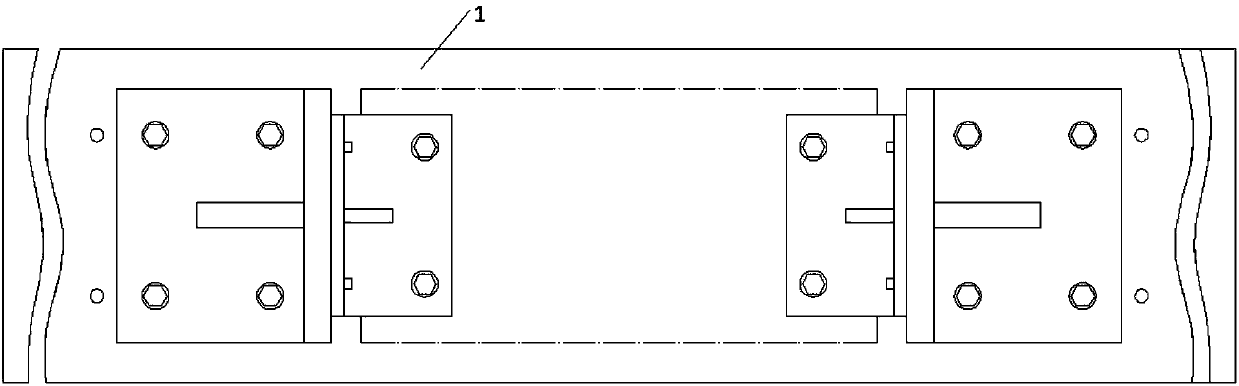

[0030] A device for improving the quality of laser drilling of plates, combined with an attached figure 1 and 2 As shown, including base 1, base bolt hole 2, large bracket bolt 3, large bracket 4, large bracket bolt hole 5, small bracket bolt 6, small bracket 7, locking bolt 8, rubber block 9, upper cover plate 10, The workpiece 11, the lower cover plate 12, the support plate 13; the large support 4 is installed on the base 1; the small support 7 is installed on the large support 4; the upper protective material 10 is placed on the workpiece 11; the lower protective material 12 is placed on the workpiece 11 below; the workpiece 11 is set on the support plate 13 .

[0031] The large support 4 is connected with the base 1 through the large support bolt 3; the small support 7 is connected with the large support 4 through the small support bolt 6;

[0032] A corresponding number of base bolt holes 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com