Cutting fluid collecting tank of lathe chip filtering device

A filtering device and cutting fluid technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as no good solution, difficulty in seeing the filtering situation, inconvenient use, etc., and achieve adjustment The irradiation angle is convenient, the lighting effect is good, and the effect is not easy to be blocked

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

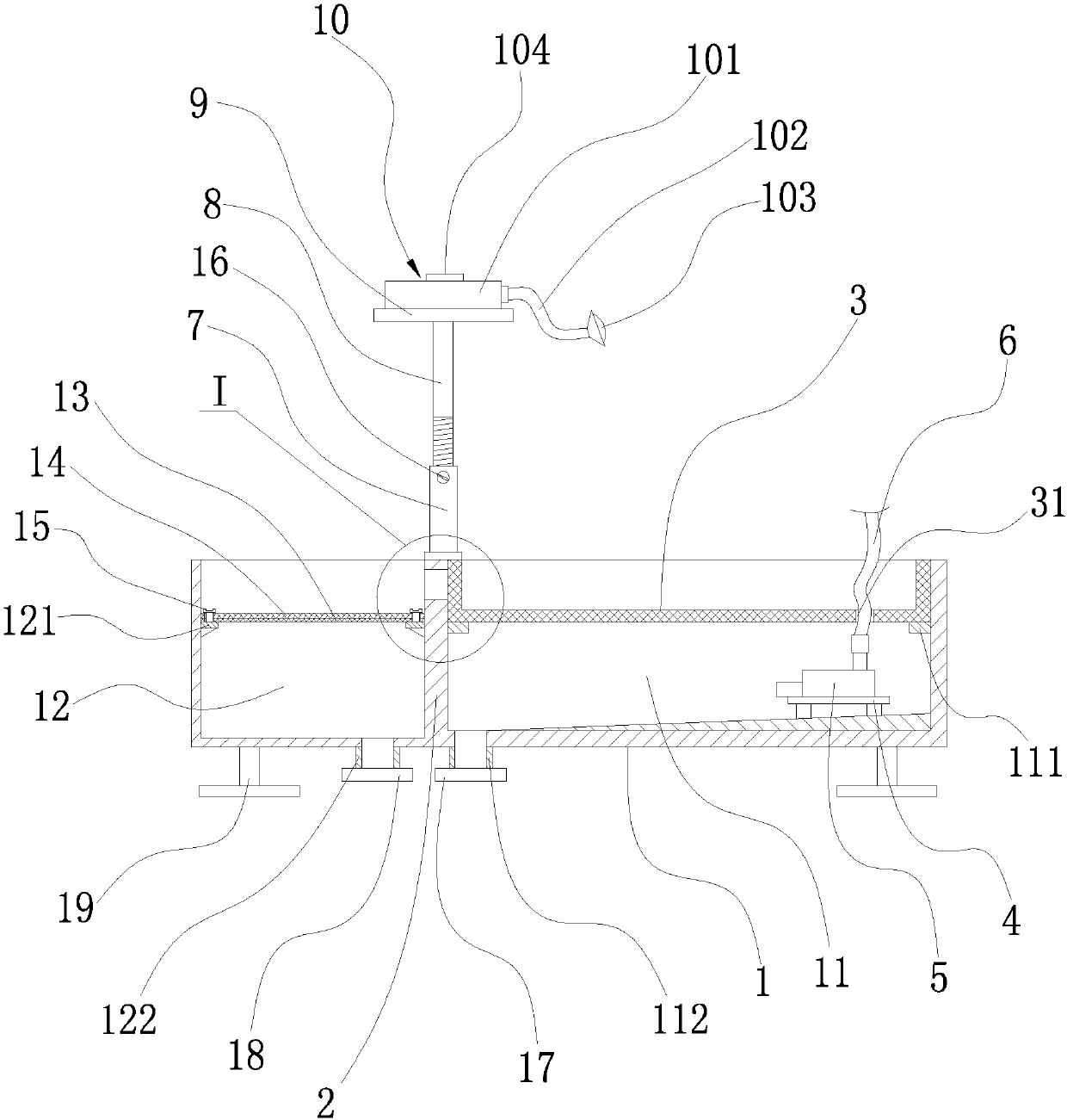

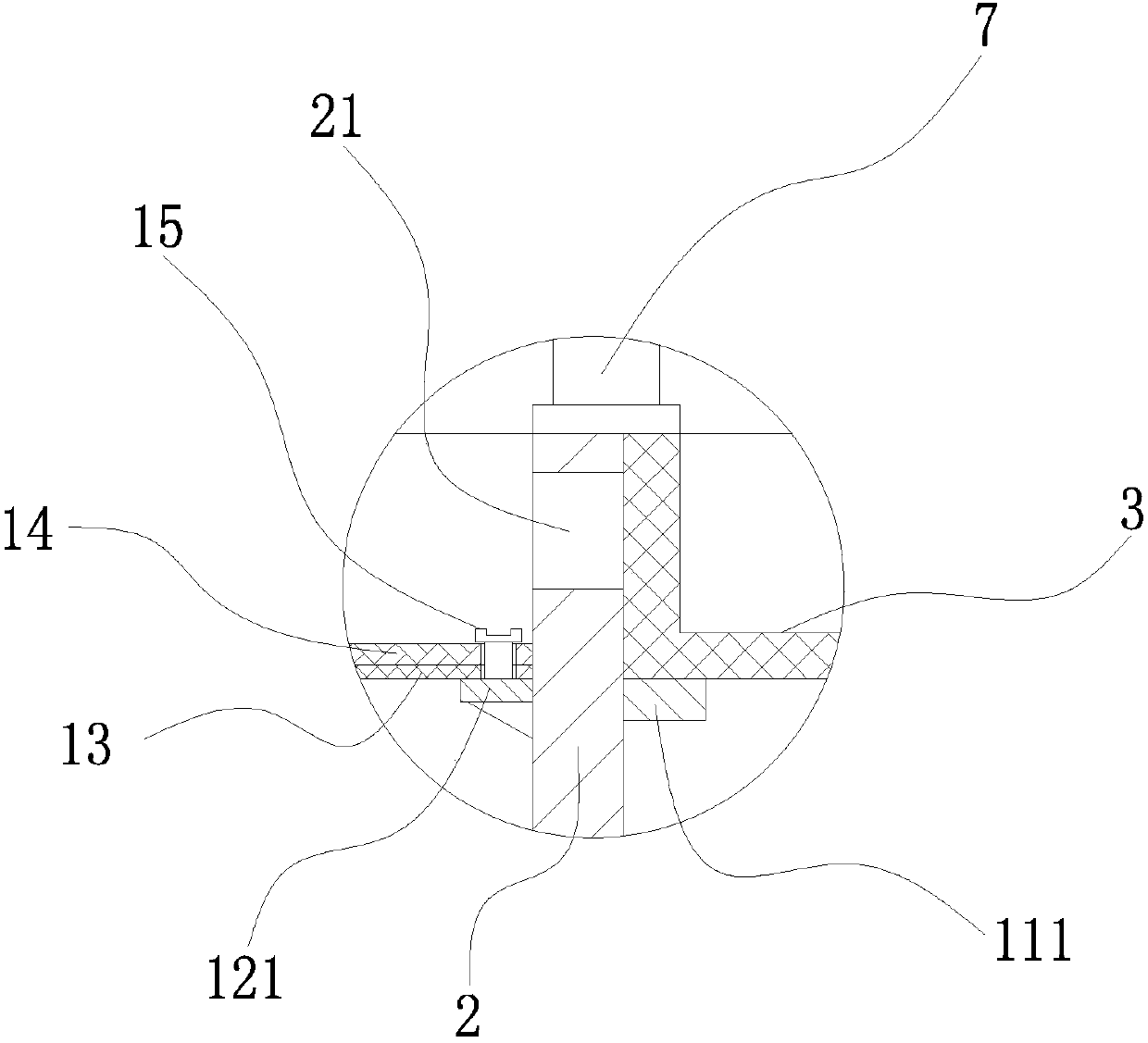

[0027] Example: such as figure 1 with figure 2 As shown, a cutting fluid collection tank of a lathe chip filter device includes a cutting fluid collection tank body 1, a partition plate 2 is integrally arranged in the cutting fluid collection tank body 1, and the cutting fluid collection tank body 1 passes through the partition The plate divides 2 into a first cutting fluid collection chamber 11 and a second cutting fluid collection chamber 12, the upper end of the partition plate 2 is provided with a floating oil outlet 21, and the inner wall of the first cutting fluid collection chamber 11 is integrally provided with A first positioning convex ring 111, a first filter screen 3 is arranged on the first positioning convex ring 111, the inner bottom surface of the first cutting fluid collection chamber 11 is arranged upward from left to right, the first The right end of the inner bottom surface of the cutting fluid collection chamber 11 is fixedly provided with a water pump b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com