Automatic polishing compound machine for columnar hardware

A hardware and compound machine technology, applied in the field of automatic polishing compound machines, can solve the problems of uneven polishing surface, difficult to guarantee polishing quality, low processing efficiency, etc., and achieve the effects of improving processing efficiency, saving manpower and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

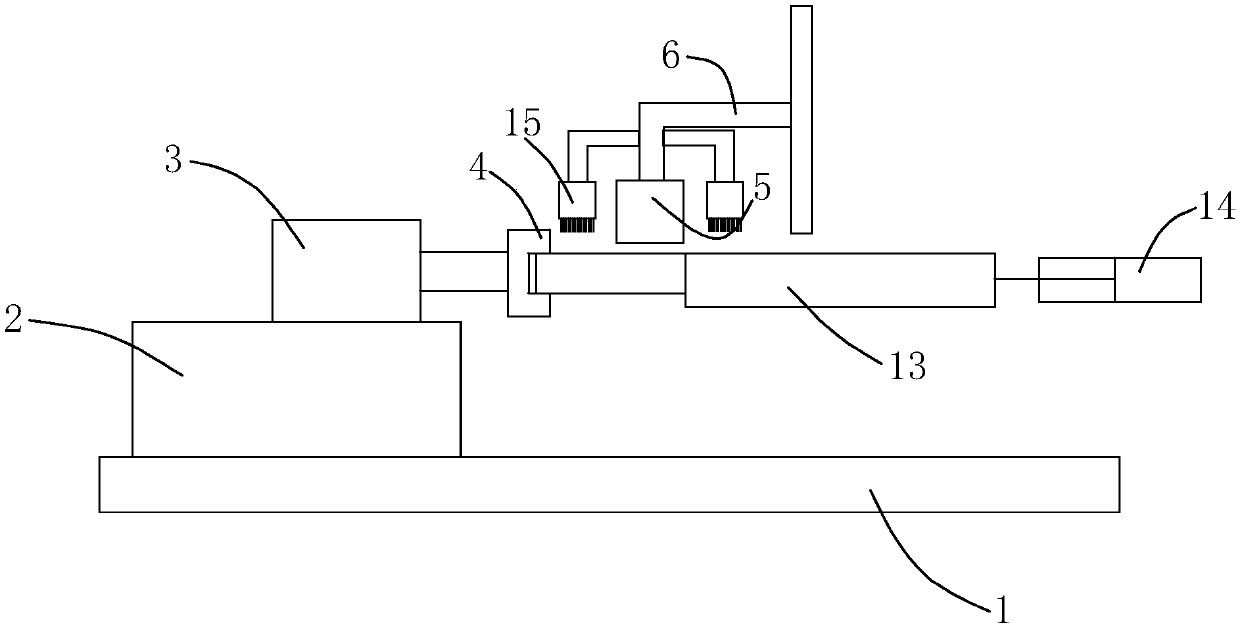

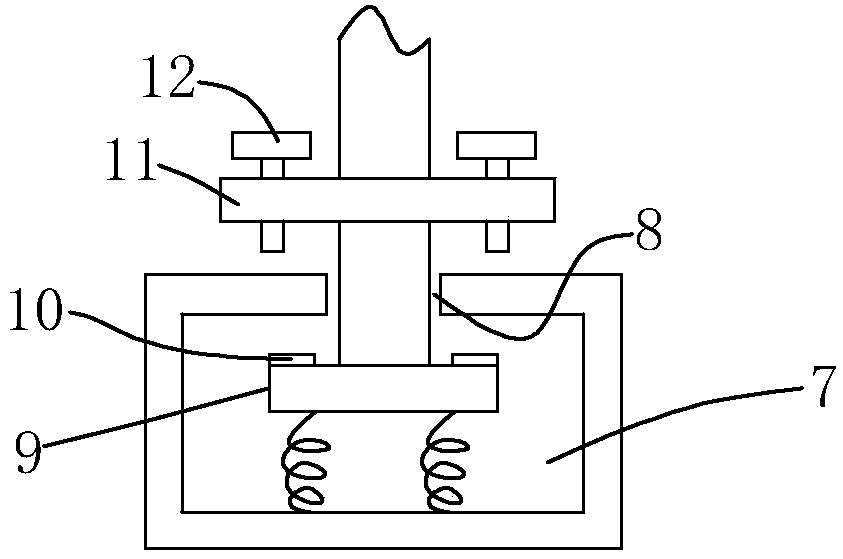

[0016] refer to Figure 1 to Figure 2 , an automatic polishing compound machine for columnar hardware of the present invention, comprising a frame, a slide rail 1 is horizontally arranged on the frame, and a slide block 2 is embedded on the slide rail 1, and the slide block 2 can be Sliding freely along the slide rail 1, a motor 3 is fixed on the slider 2, the end of the output shaft of the motor 3 is provided with a chuck 4 for installing hardware, and the slider 2 is connected with a A drive device for reciprocating left and right, the frame is also provided with a polishing head 5, the polishing head 5 can move up and down through the bracket 6 and is installed on the frame, and the polishing head 5 is fixed on the frame by a locking device 12 On the frame, cleaning brushes 15 are fixedly arranged on both sides of the polishing head 5, and the three of the two cleaning brushes 15 and the polishing head 5 are collinear, and the straight line is parallel to the axis of the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com