Cylindrical pile leg

A cylindrical pile and pile leg technology, which is applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of increasing the weight and size of pile legs, increasing the difficulty and cost of making pile leg cylinders, and achieving the weight of pile legs Reduce, save variable loads, and reduce the difficulty of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

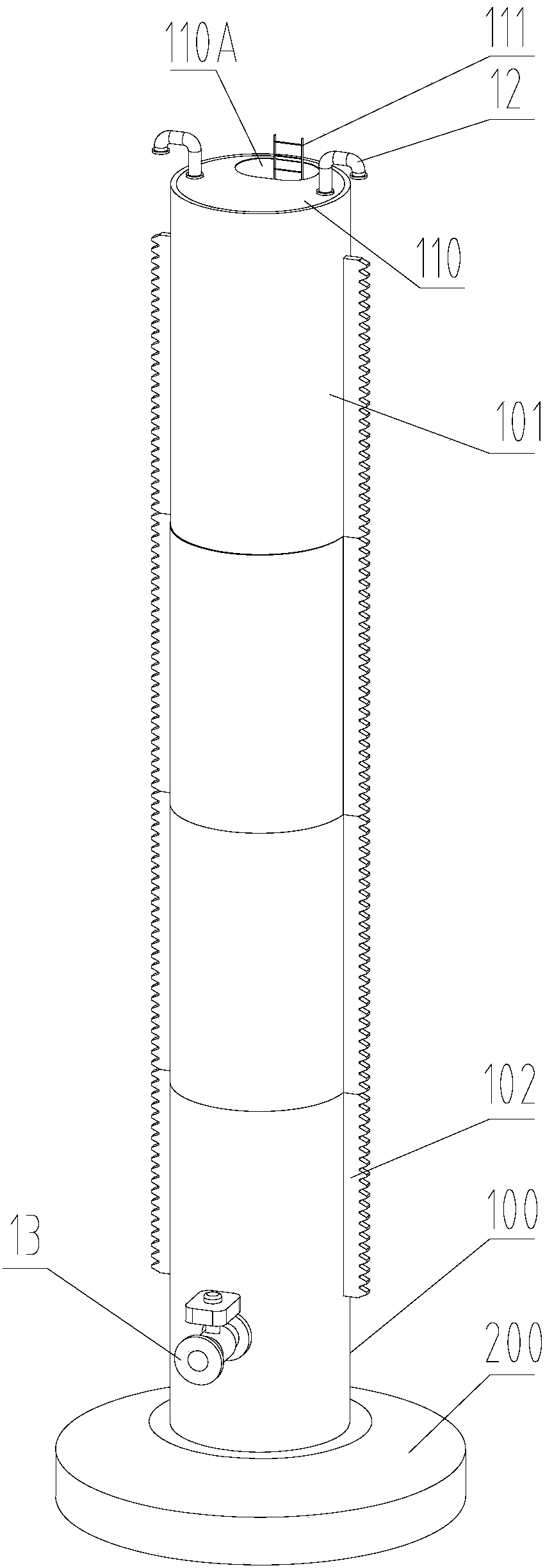

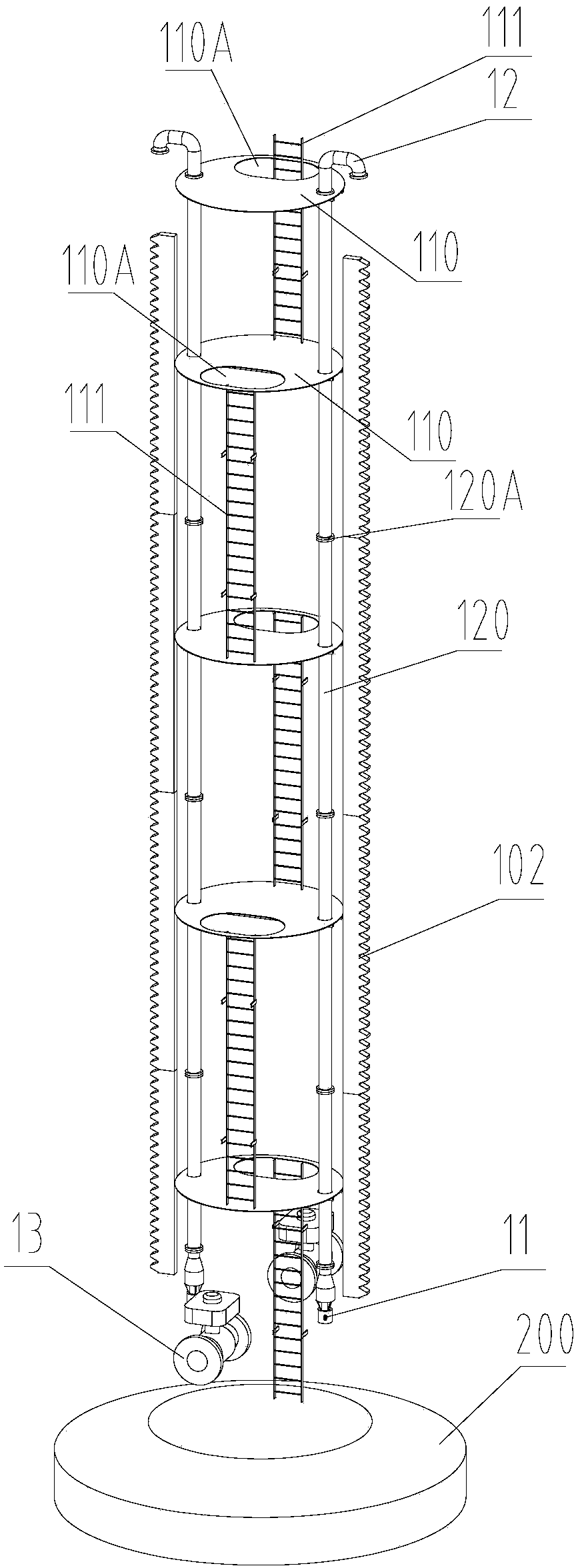

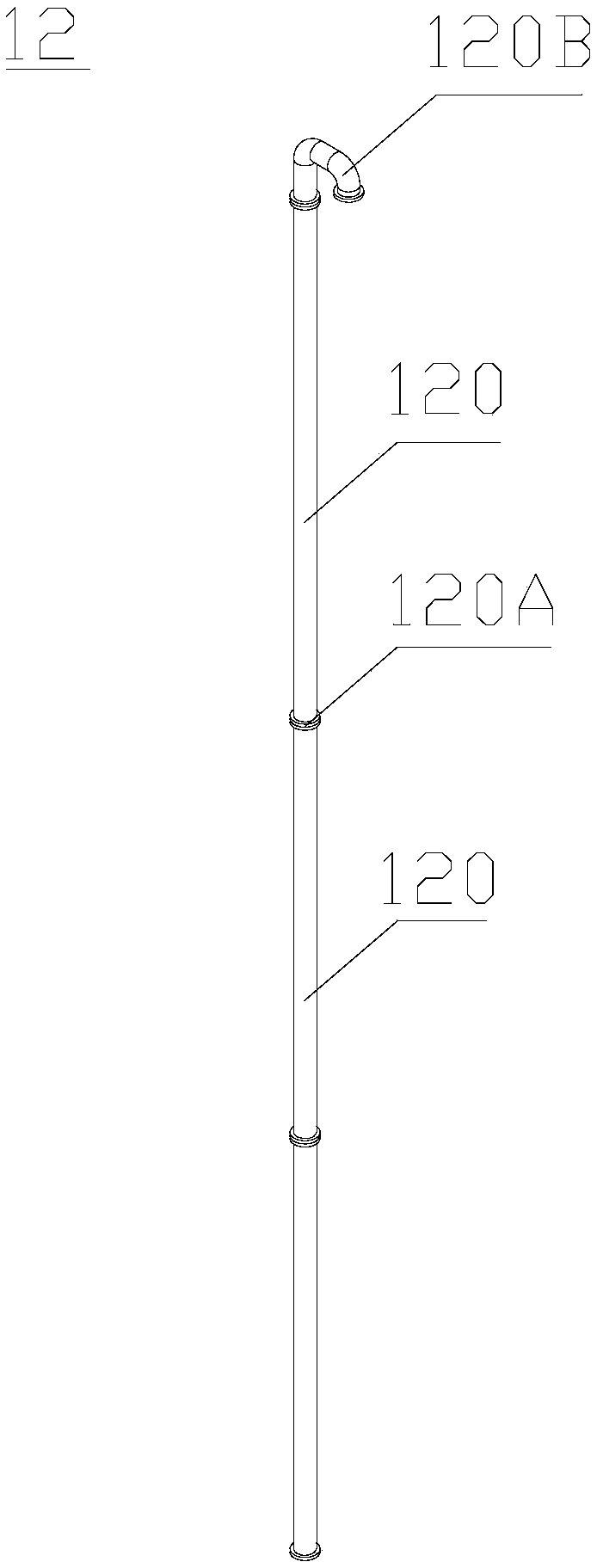

[0027] figure 1 It is a structural schematic diagram of a cylindrical pile leg provided by an embodiment of the present invention, figure 2 yes figure 1 The schematic diagram of the internal structure of the cylindrical pile legs shown, see figure 1 and 2 , the cylindrical leg includes a leg body 100, a submersible pump 11, a drain pipe 12 and a remote control valve 13, the bottom end of the leg body 100 is used to connect with the spud shoe 200, and the leg body 100 is close to A remote control valve 13 is arranged on the side wall of the bottom end, and the remote control valve 13 is used to control whether the inner cavity of the leg cylinder 100 communicates with the outside of the leg cylinder 100, and the submersible pump 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com