Auxiliary suction mechanism for sewage suction truck and sewage suction truck

A technology for sewage suction trucks and sewage pipes, which can be used in waterway systems, water supply devices, buildings, etc., and can solve problems such as blockage of sewage suction pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

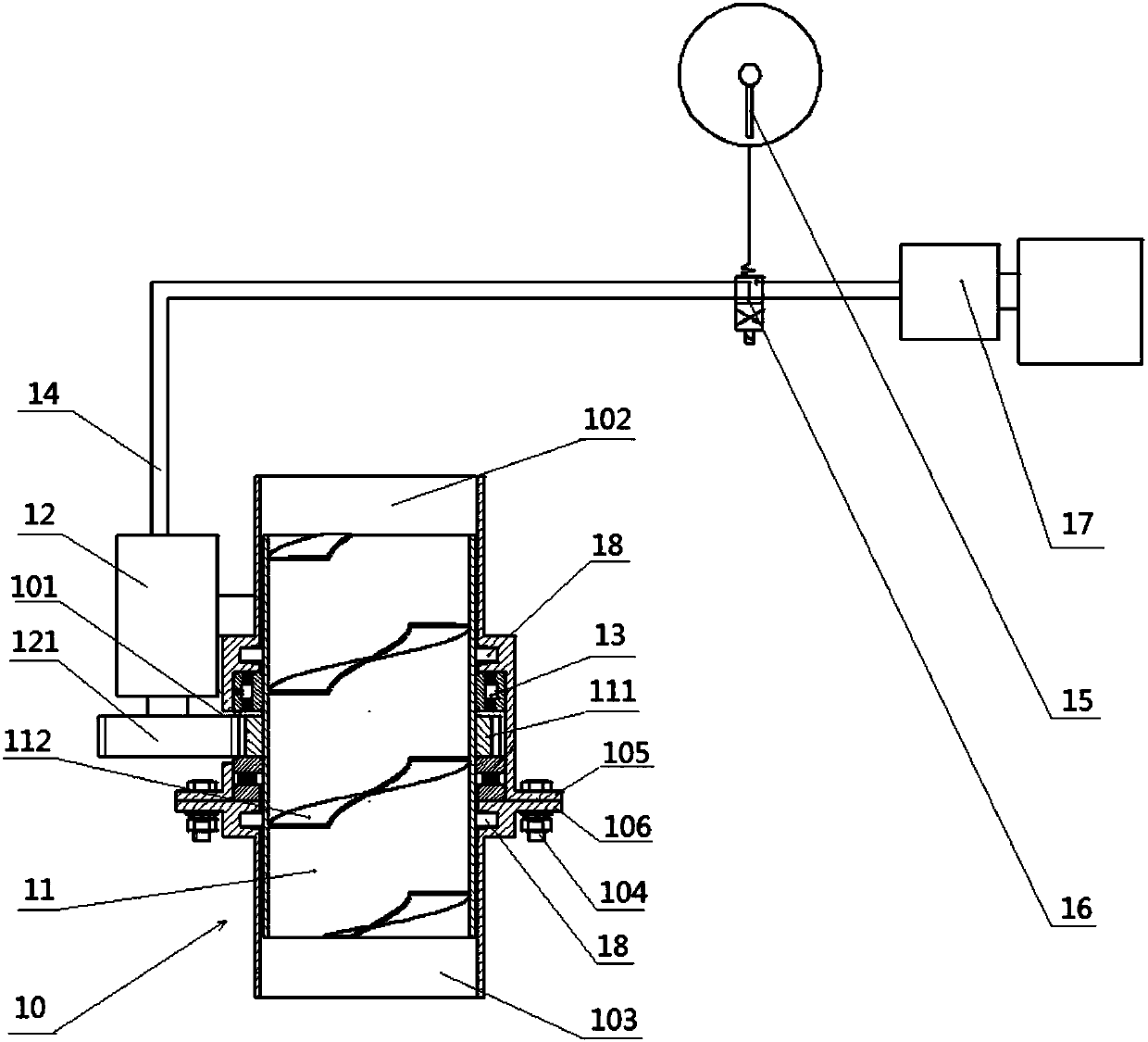

[0038] see figure 1 , this embodiment provides an auxiliary suction mechanism for a sewage suction truck, including an outer cylinder 10, an inner cylinder 11, a hydraulic motor 12, a bearing 13, an oil guide pipe 14, a negative pressure sensor 15, an electromagnetic reversing valve 16 and a gear pump 17 The fuselage of the hydraulic motor is arranged on the outer surface of the outer cylinder, the outer surface of the inner cylinder is provided with outer teeth 111, and the middle part of the outer cylinder is provided with a station hole 101, and the transmission gear 121 of the hydraulic motor is meshed with the outer teeth through the station hole , the bearing is arranged between the outer cylinder and the inner cylinder, and the inner wall of the inner cylinder is provided with a helical blade 112; the oil guide pipe is arranged between the output end of the gear pump and the input end of the hydraulic motor, and the electromagnetic reversing valve is arranged on the oil ...

Embodiment 2

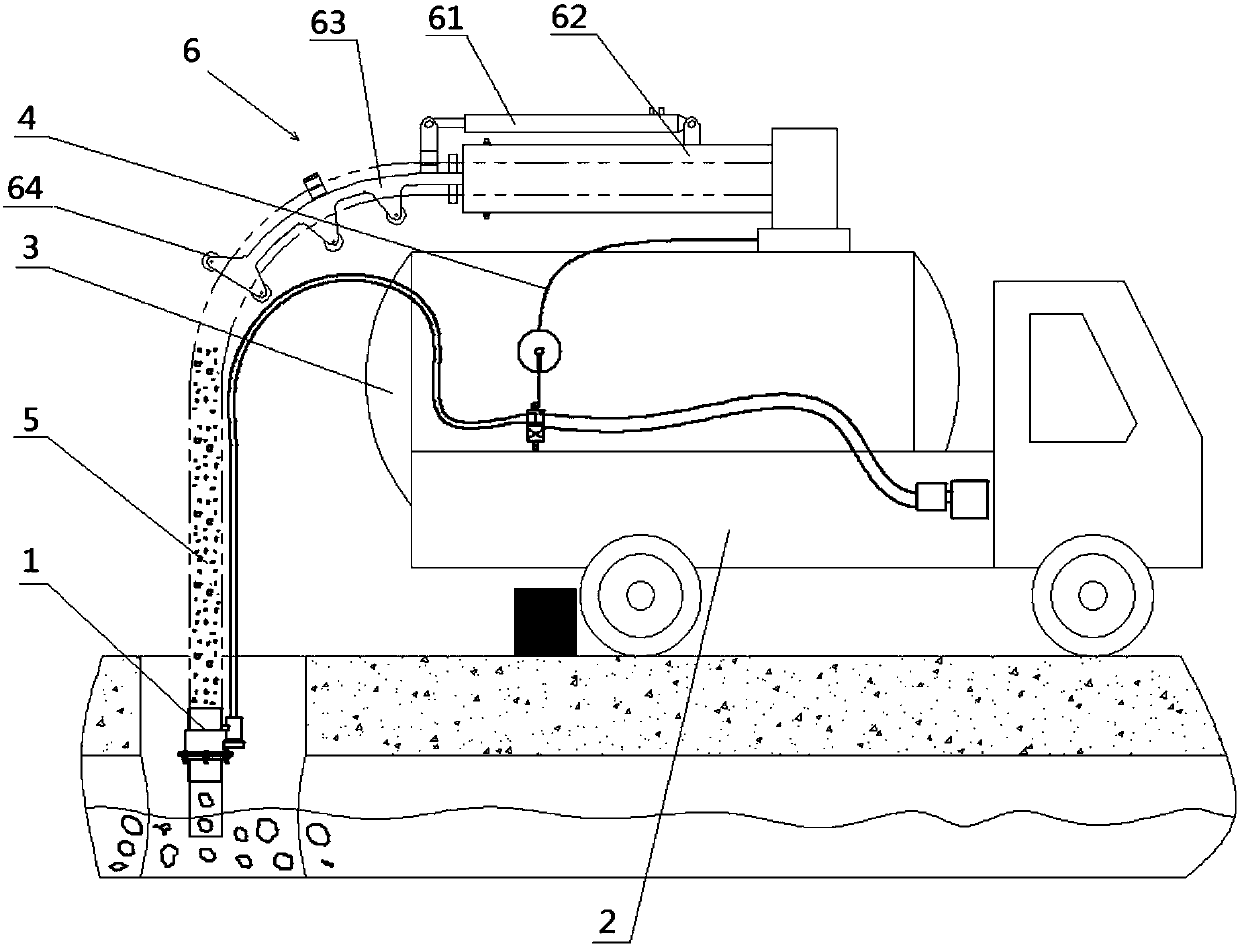

[0045] see figure 2 , this embodiment also provides a sewage suction vehicle with an auxiliary suction mechanism, including an auxiliary suction mechanism 1, a vehicle body 2, a storage tank 3, a vacuum pressure measuring hose 4 and a sewage suction pipe 5; the auxiliary suction The mechanism is the auxiliary suction mechanism described in any one of claims 1 to 5; the storage tank is arranged on the vehicle body of the car body, and the vacuum pressure measuring hose is connected between the storage tank and the negative pressure sensor to assist the suction. The mechanism is arranged at the inlet end of the sewage suction pipe, the outlet end of the sewage suction pipe is connected to the feed port of the storage tank, and the gear pump of the auxiliary suction mechanism is arranged on the power take-off of the car body. The power take-off for the car body is composed of one or more sets of speed change gears, also known as power output devices, which are generally composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com