Construction method of prefabricated part and cast-in-place column assembly integral concrete frame structure

A technology of frame structure and cast-in-place columns, which is applied in the direction of building construction and construction, can solve the problems of low seismic performance and achieve the effects of improved seismic performance, improved construction efficiency, and improved integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

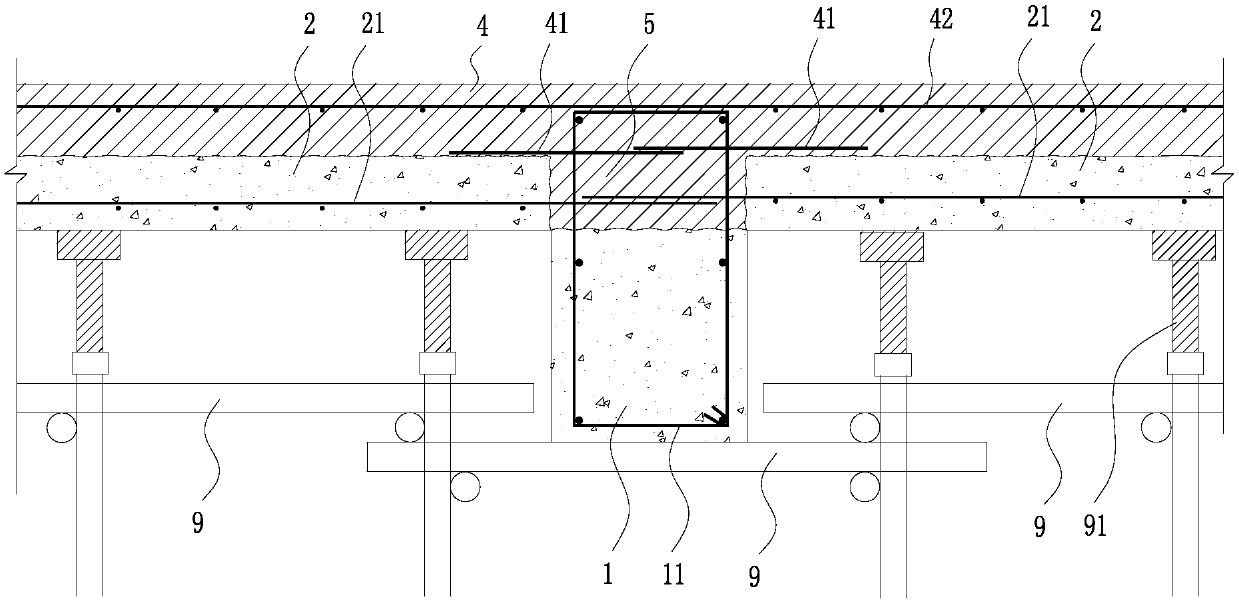

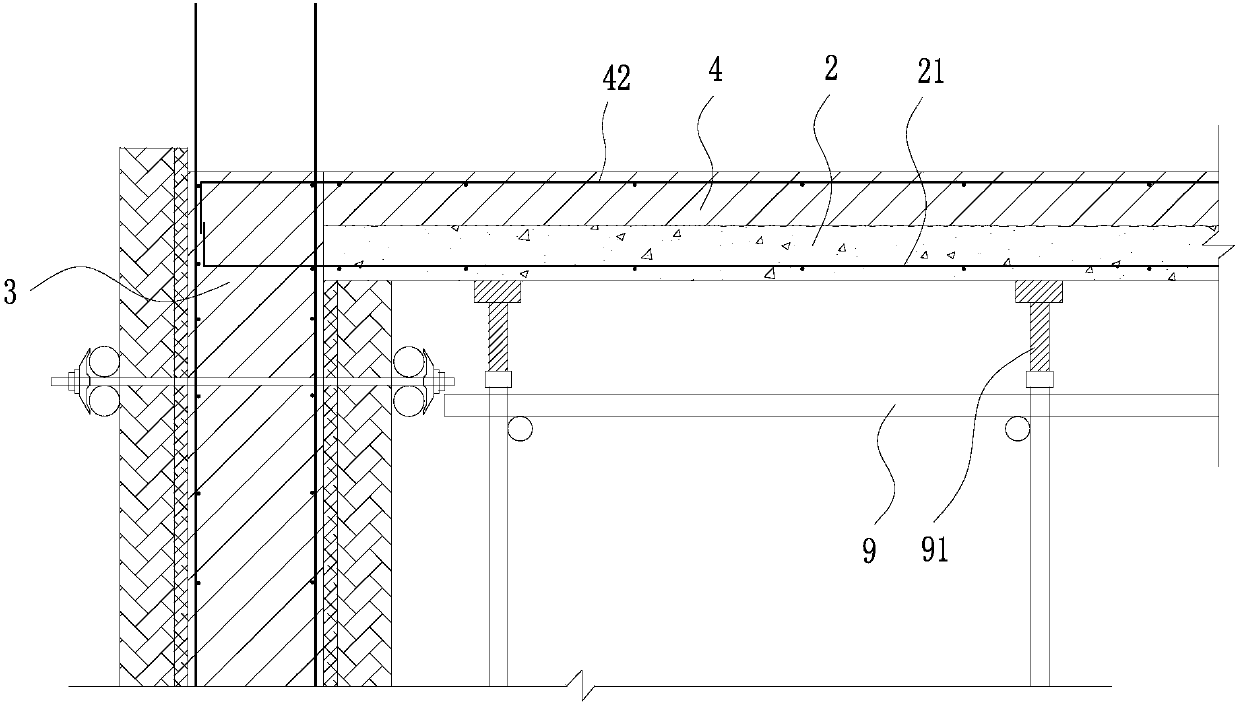

[0053] see Figure 1 to Figure 5, the construction method of prefabricated parts and cast-in-situ columns assembling integral concrete frame structure of the present invention, comprises the following steps:

[0054] S1. Preparation of prefabricated parts, the prefabricated parts include prefabricated beams and prefabricated slabs, and the ends of the prefabricated beams and prefabricated slabs are provided with tendons;

[0055] S2. Site leveling, measurement and setting out;

[0056] S3. Bracket erection;

[0057] S4. Hoisting of prefabricated parts;

[0058] S5. Binding of steel bars, binding the beard bars of prefabricated beams and prefabricated slabs with the steel bars of cast-in-place columns;

[0059] S6. The concrete is poured to form a cast-in-place column, and the cast-in-place column and the prefabricated part are poured as one;

[0060] S7. Conservation.

[0061] In the construction method of prefabricated parts and cast-in-place columns assembling an integr...

Embodiment 2

[0090] see Figure 6 , In this embodiment, only the use of cast-in-situ columns, prefabricated beams, and prefabricated slabs is limited, and there is no restriction on the stairs, and there is no restriction on whether to re-cast the floor slab.

Embodiment 3

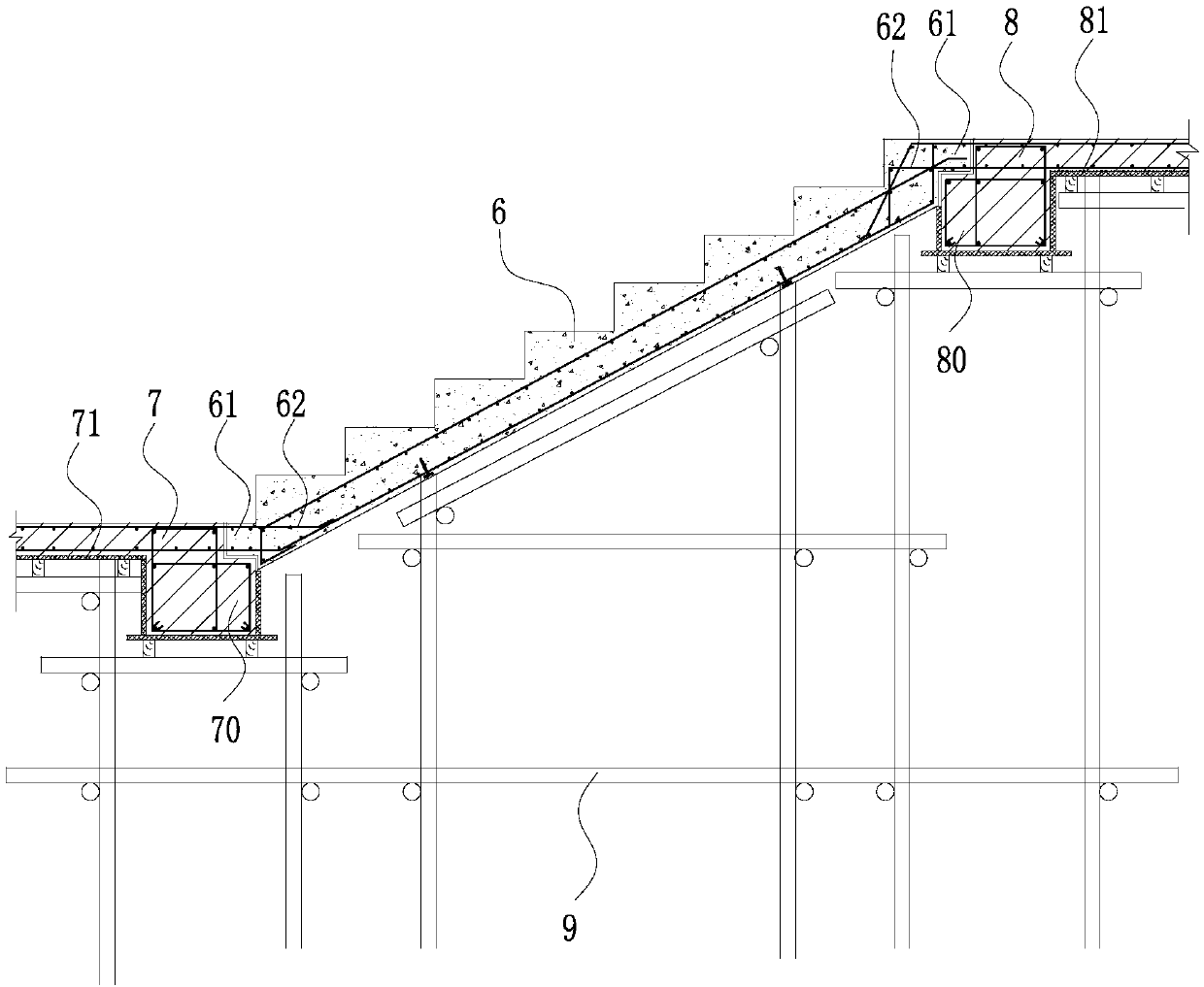

[0092] see Figure 7 , in this embodiment, it is limited to cast-in-place floor slabs in addition to prefabricated beams and prefabricated slabs. In step S6, the concrete is poured to form a cast-in-place column and a cast-in-place floor slab, and prefabricated slabs are placed on both sides of the upper surface of the prefabricated beam, the upper surface of the prefabricated beam is aligned with the lower surface of the prefabricated slab, and the pouring of the cast-in-place beam is formed above the prefabricated beam space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com