Jet flow control-type fertilization pump

A technology for jet control and fertilization pumps, which is applied to jet pumps, fertilization devices, non-volume pumps, etc., can solve the problems of high piston movement resistance, poor sealing between piston and cylinder, and impossibility to achieve increased stability and increased Sealing, drag reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] For doing further understanding to the present invention, now in conjunction with accompanying drawing, the present invention is described further:

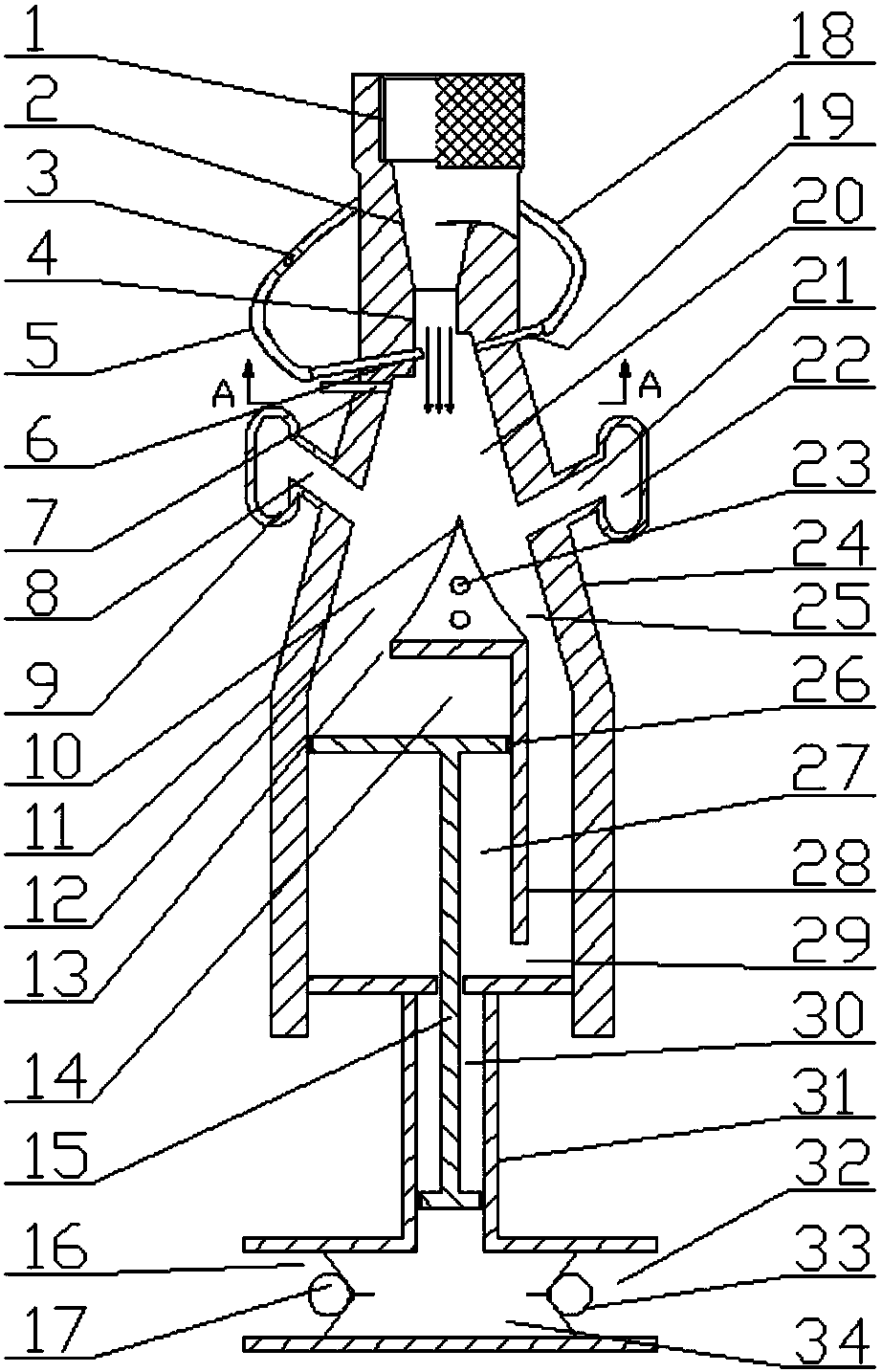

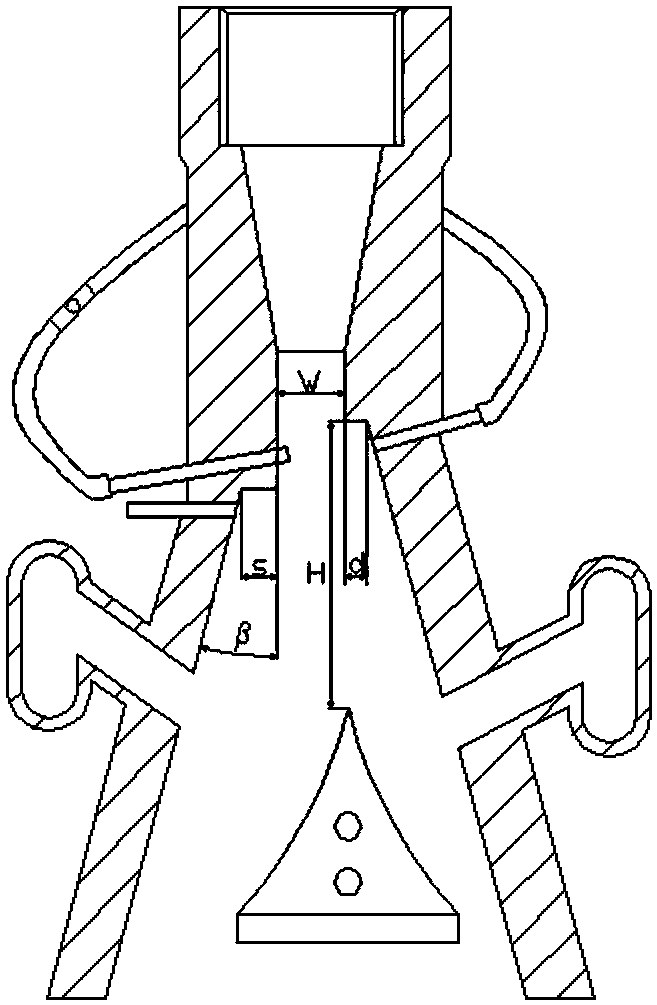

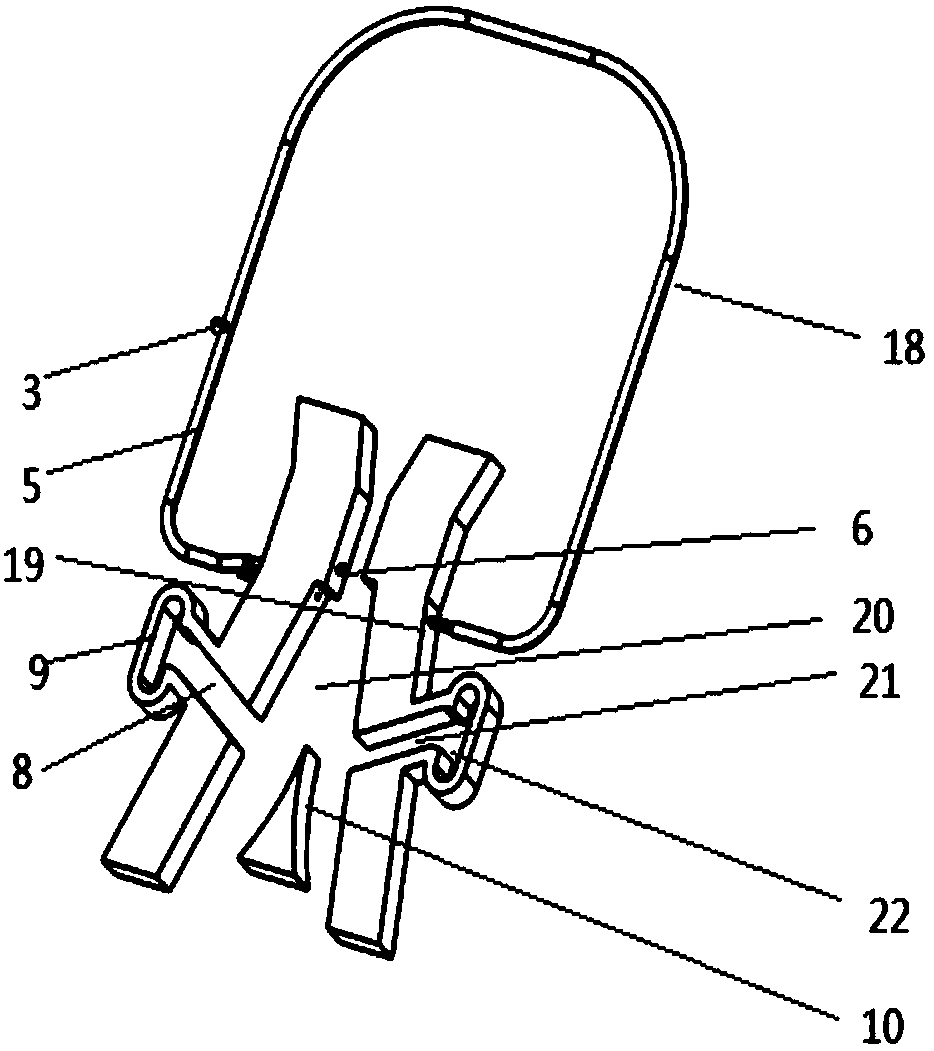

[0035] combined with figure 1 , figure 2 , image 3 , Figure 4 with Figure 5, the jet control fertilization pump includes a jet element, a water intake nozzle 6, a left rubber conduit 5, an air supply tee pipe 3, a right rubber conduit 18, a water inlet 19, a reverse air supply hole 7, a piston assembly 15 and a cylinder 31; The jet element includes a threaded inlet 1, a contraction section 2, a guide section 4, a jet space 20, a left emptying channel guiding section 8, a left emptying channel outlet 9, a right emptying channel guiding section 21, a right Evacuation channel outlet 22, left output channel 12, right output channel 25, propulsion chamber inlet 13, reset chamber inlet 29; the front end of the jet element is threaded inlet 1, threaded inlet 1 is connected to shrinkage section 2, and shrinkage section 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com