Bolt and nut fastening assembly

A technology for fastening components, bolts and nuts, applied in the direction of threaded fasteners, locking fasteners, nuts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

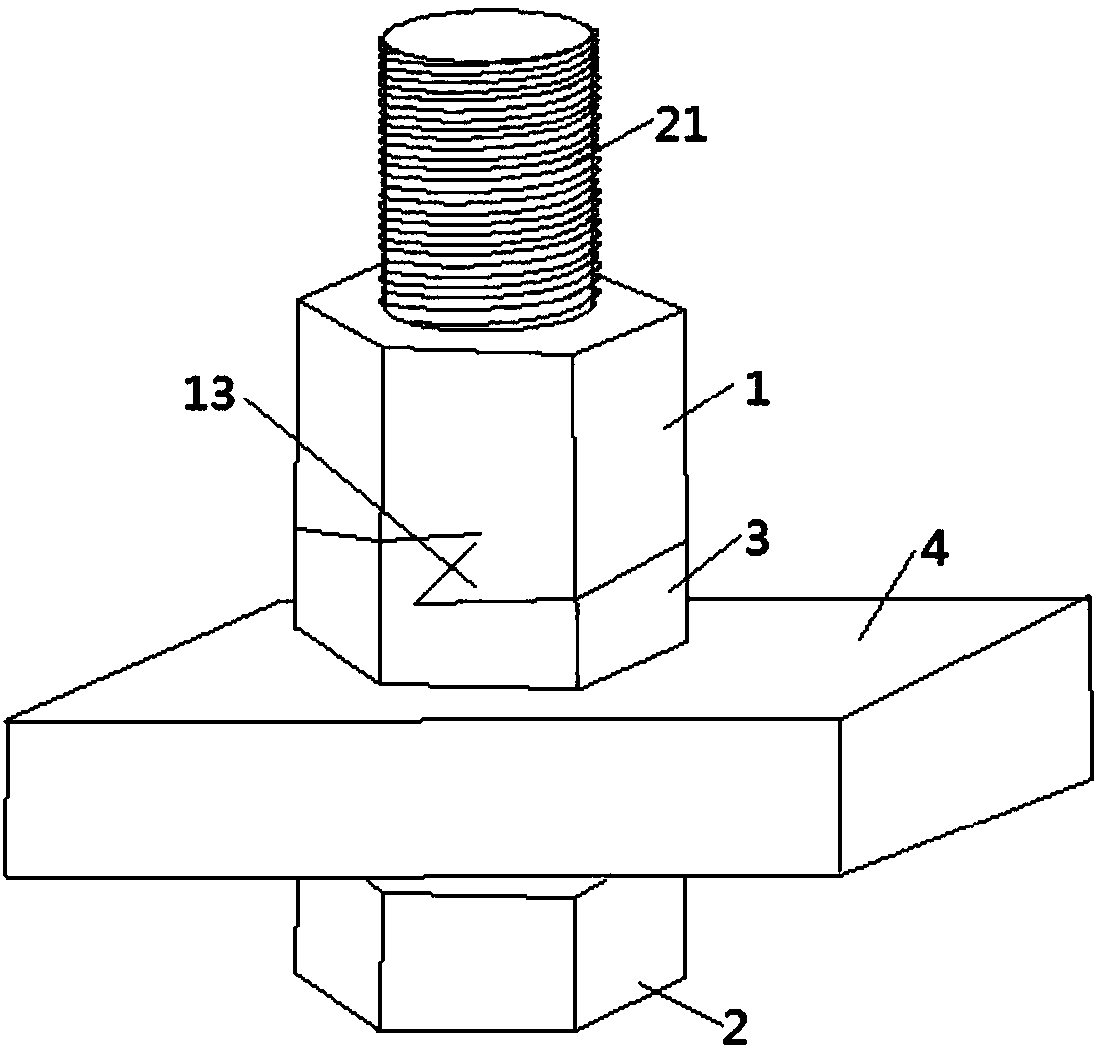

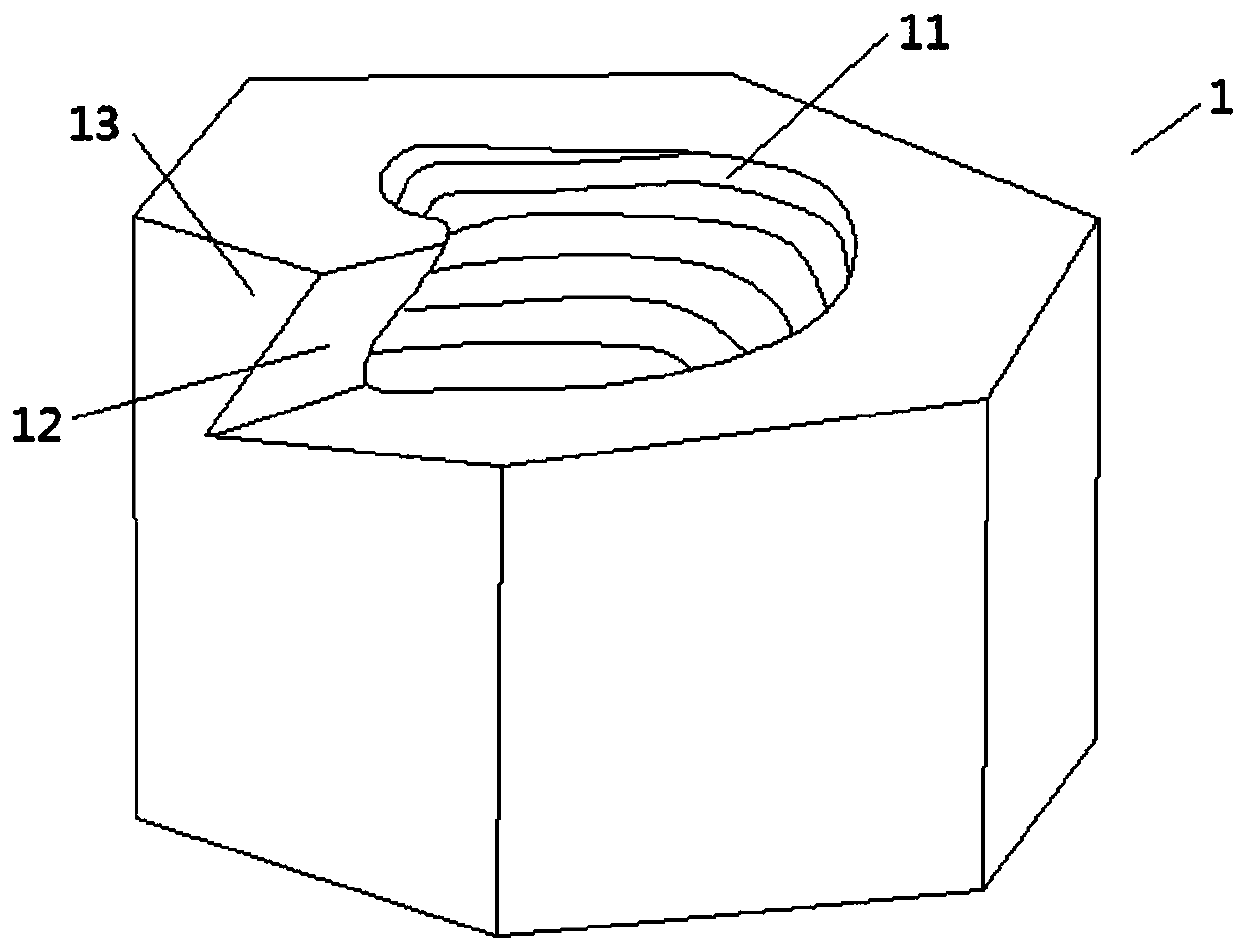

[0023] Such as figure 1 Shown in three dimensions for fastening components Figure 1 , including fastening nut body 1, bolt 2 and washer 3, image 3 It is a three-dimensional view of the fastening nut body, the contact surface between the fastening nut body 1 and the washer 3 is a spiral curved surface, and the spiral curved surface is formed by a point on the central axis of the fastening nut body and outside the fastening nut body The connecting line at the same height on the side rotates at a constant speed around the central axis of the fastening nut body and moves at a constant speed along the central axis of the fastening nut body, wherein the rotation angle is 370°, and the washer 3 and the bolt 2 will Fastener 5 is fastened in the middle.

[0024] The rotation angle of the spiral curved surface is set to be greater than 360°, and the line connecting a point on the central axis of the fastening nut body and a point on the outer surface of the fastening nut body at the...

Embodiment 2

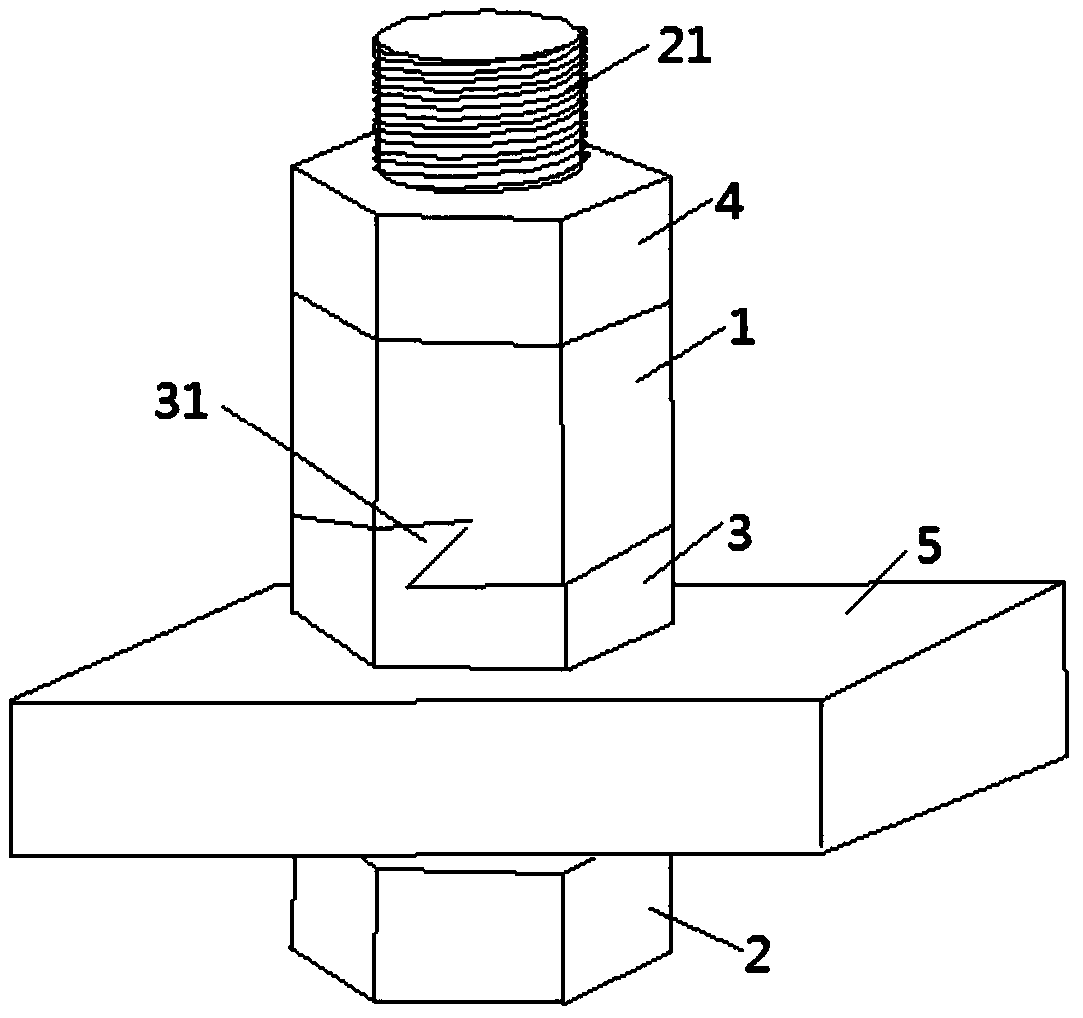

[0031] Such as figure 2 Shown in three dimensions for fastening components Figure II , including fastening nut body 1, bolt 2 and washer 3, image 3 It is a three-dimensional view of the fastening nut body, the contact surface between the fastening nut body 1 and the washer 3 is a spiral curved surface, and the spiral curved surface is formed by a point on the central axis of the fastening nut body and outside the fastening nut body The connecting line at the same height on the side rotates at a constant speed around the central axis of the fastening nut body and moves at a constant speed along the central axis of the fastening nut body, wherein the rotation angle is 370°, and the washer 3 and the bolt 2 will Fastener 5 is fastened in the middle.

[0032] The rotation angle of the spiral curved surface is set to be greater than 360°, and the line connecting a point on the central axis of the fastening nut body 1 and a point on the outer surface of the fastening nut body 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com