Self-energy-supply magnetorheological damper and working method thereof

A magneto-rheological damper and self-supply technology, which is applied in shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of large structures and poor adaptation, and ensure the induction current and structure Simple, Maximum Results Guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

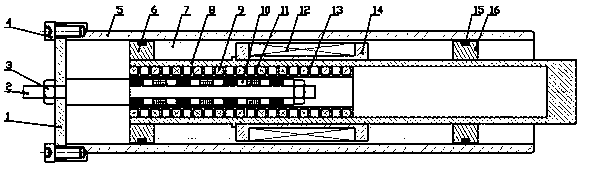

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

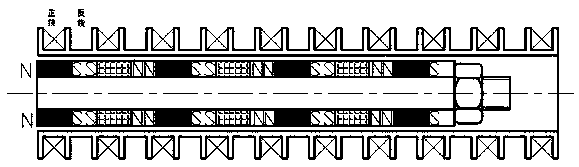

[0017] As shown in the figure, a self-powered magneto-rheological damper includes a hollow piston rod 8, a magnetorheological damper system and an energy recovery system, and the energy recovery system includes an induction coil sleeve 13 fixed inside the piston rod The magnetic ring shaft 2 is arranged in the induction coil sleeve, and the external impact suffered by the piston rod 8 makes the magnetic ring shaft 2 and the induction coil sleeve 13 move relative to each other to generate magnetic induction line cutting and then generate an induced current to provide working power for the magneto-rheological damper system .

[0018] The magneto-rheological fluid damper system includes a left piston 6, a right piston 16 and a coil piston 14, and the left piston 6, the right piston 16 and the coil piston 14 are jointly installed on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com