A high-pressure air large-flow on-site calibration device and method

A field calibration, high-pressure air technology, used in testing/calibration devices, measuring devices, liquid/fluid solids measurement, etc. The effect of rapid and uniform gas temperature field and reduced error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

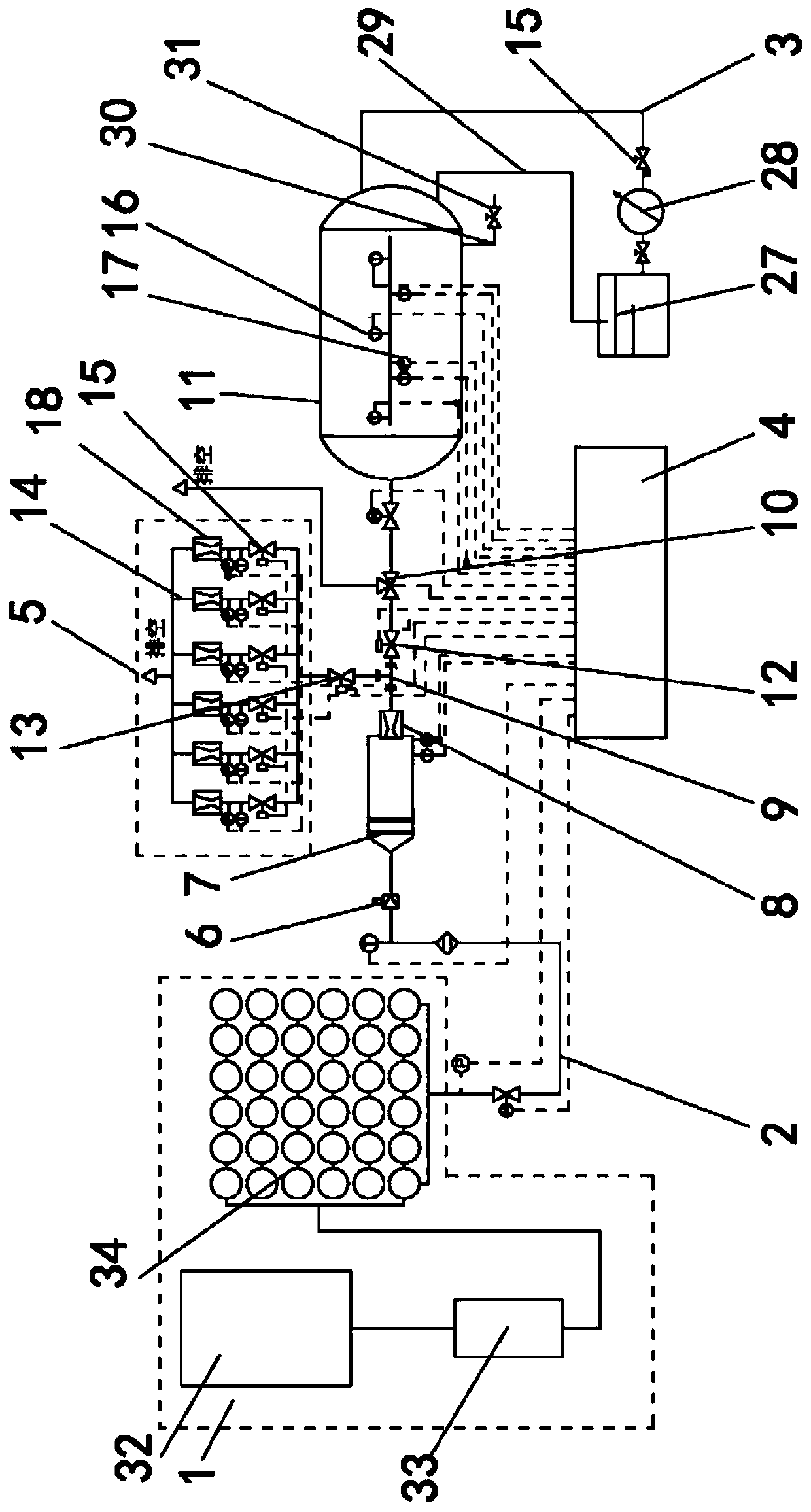

[0072] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings, so that those skilled in the art can understand and implement the present invention.

[0073] The present invention is an air flow meter calibration device, see figure 1 , the high-pressure air large-flow on-site calibration device of the present invention includes a high-pressure air source system 1, a main pipe 2, a cooling water system 3, a measurement control system 4, and a flow secondary standard system 5, which are sequentially arranged on the main pipe along the high-pressure and large-flow air flow direction. Pressure regulating device 6, voltage stabilizing and rectifying device 7, calibrated air flow meter 8, tee pipe 9, quick reversing valve 10 and standard container 11 on road 1;

[0074] The air outlet of the air flowmeter 8 to be calibrated is connected with the air inlet of the three-way pipe 9, one air outlet of the three-way pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com