Film for increasing friction between two non-positive connection components

A technology of locking connection and increasing friction, which is applied in the field of connection system, manufacture of the film, and two components of motor vehicles, which can solve the problems of complex equipment, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

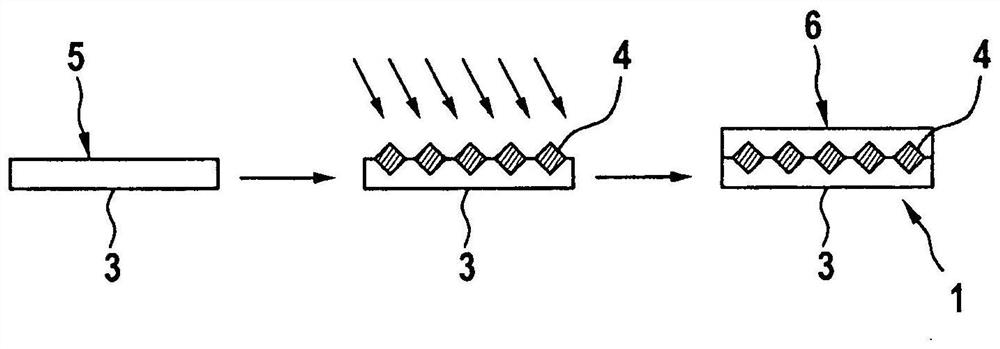

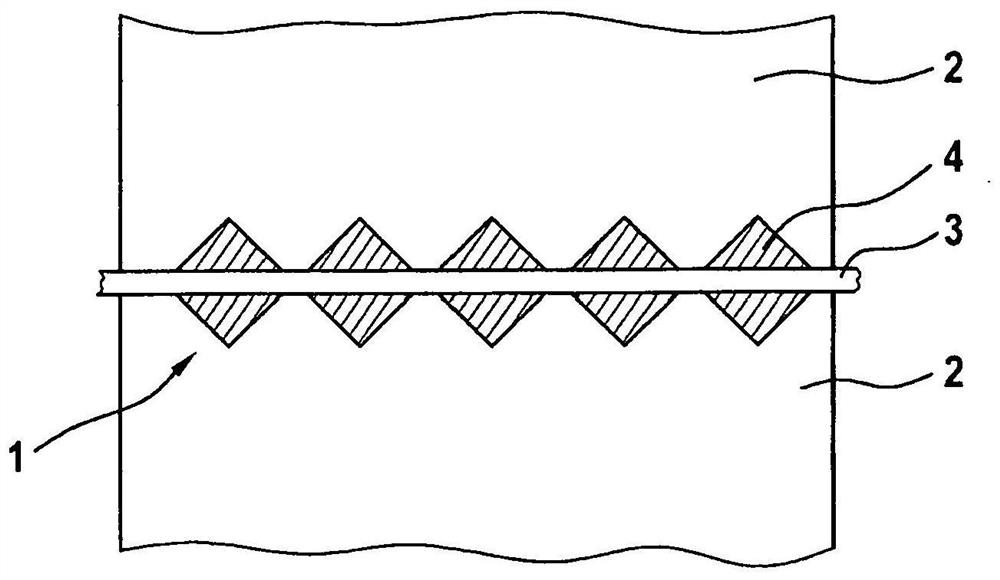

[0046] figure 1 A schematic diagram of the method according to the invention for producing the film 1 according to the invention is shown.

[0047] First, the matrix 3 is produced, for example from plastic. A plurality of hard particles 4 are to be inserted into this matrix.

[0048] figure 1 The diagram in shows a spraying method in which hard particles 4 are accelerated. When the hard particles 4 impinge on the matrix 3 , they penetrate at least partially into the matrix 3 and are thus fixed in the matrix 3 .

[0049] As an alternative to the spraying method, it is also possible to deposit hard particles 4 on the substrate 3 and to increase the pressure on the hard particles 4 on the substrate 3 . This is achieved, for example, by rolling hard particles 4 . Hard particles 4 can also penetrate into the matrix in this way.

[0050] It is in particular provided within the scope of the invention that the hard particles 4 are not connected to the matrix by means of an adhes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com