Bonding capillary

A rivet and inclined surface technology, applied in the field of welding ribbing, can solve the problems of poor peeling, poor welding rib life, poor filament cut-off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

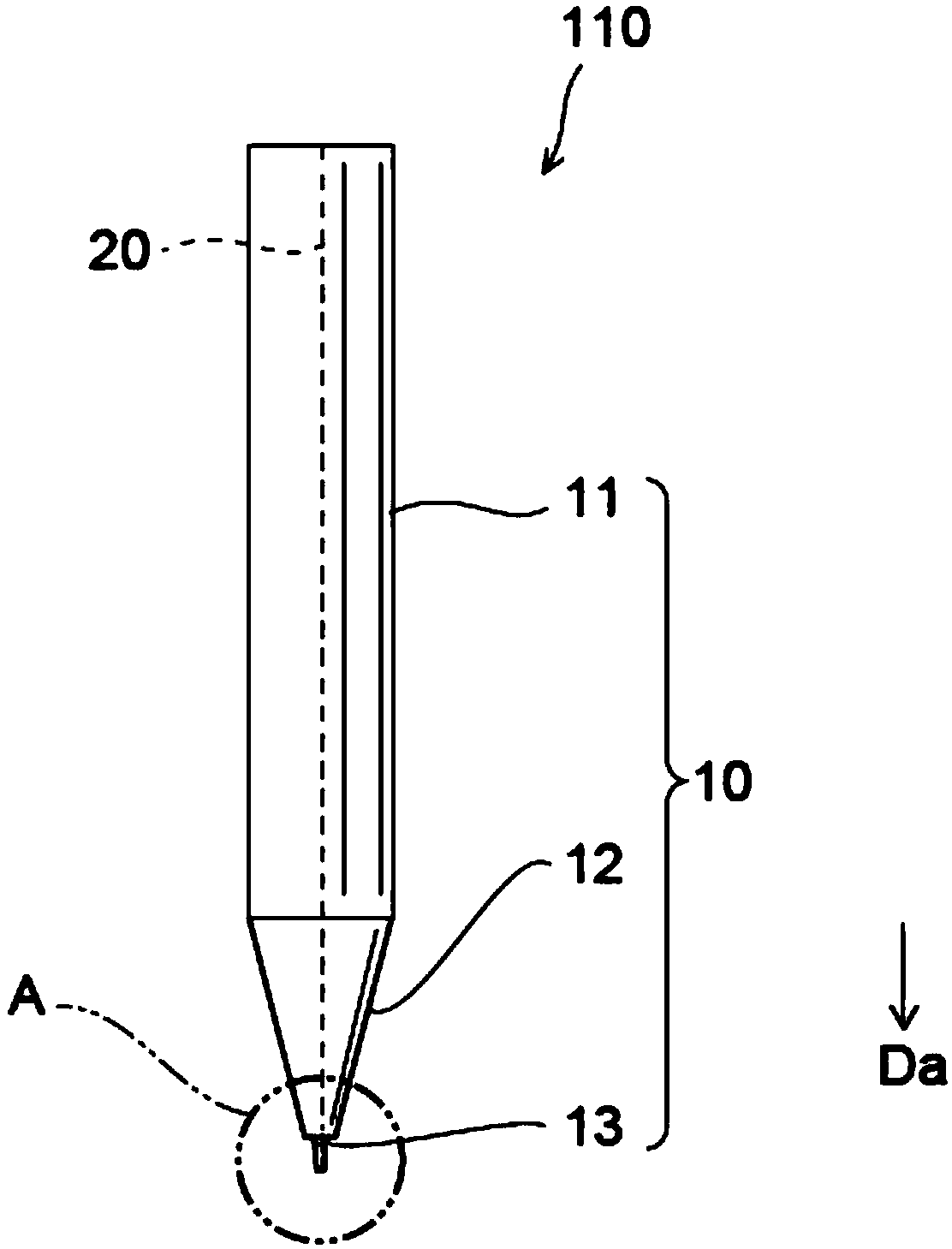

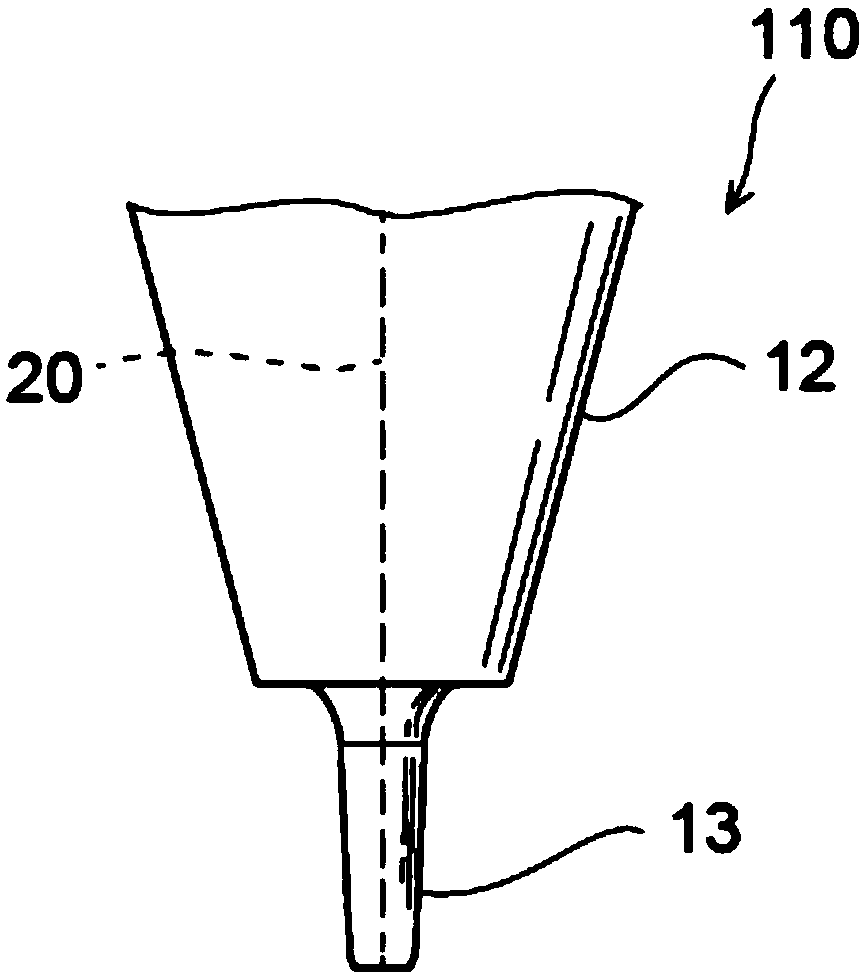

[0052] figure 1 It is a schematic diagram illustrating the welding capillary according to this embodiment.

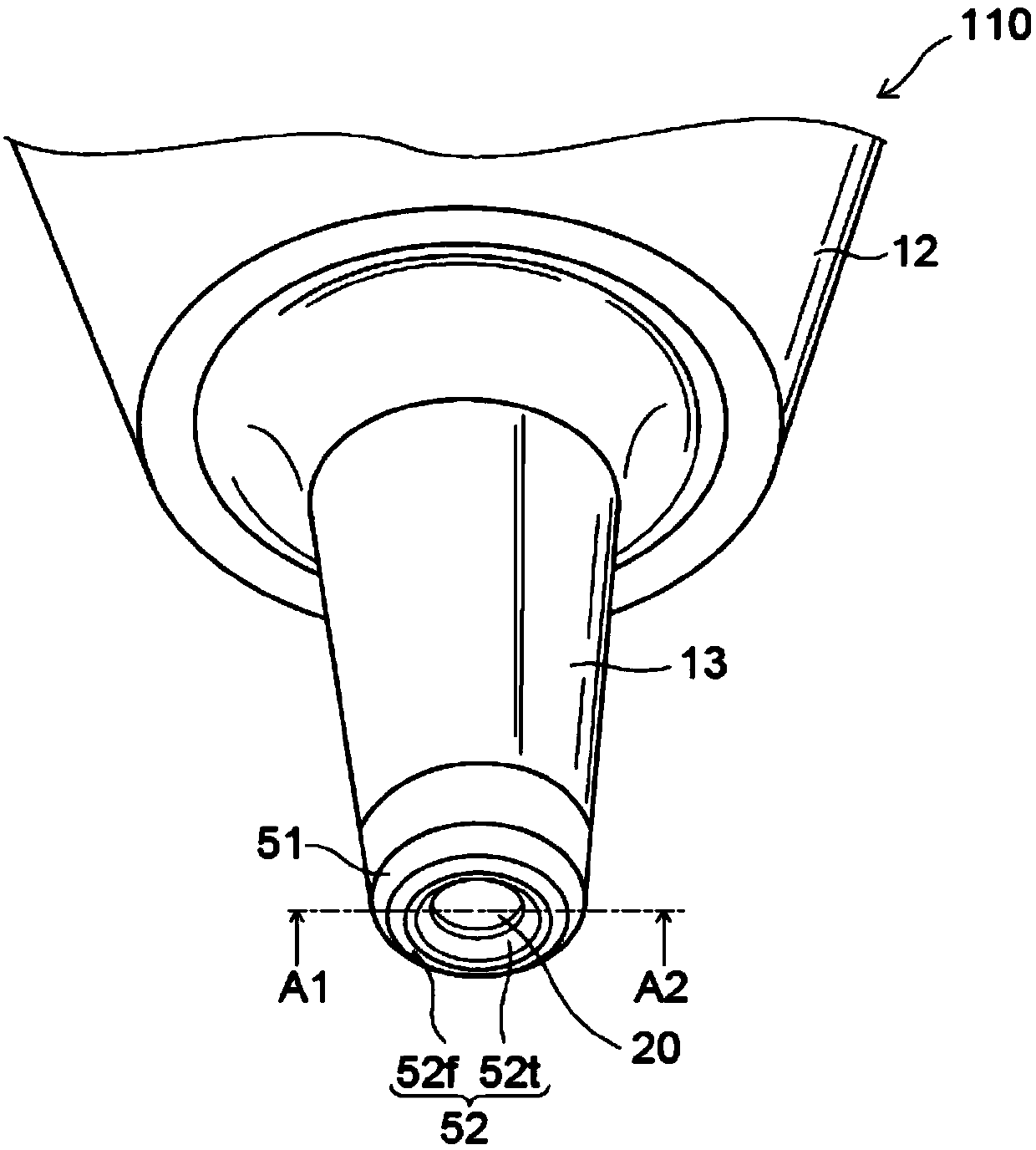

[0053] figure 2 It is a schematic enlarged view illustrating the tip shape of the welding capillary according to this embodiment.

[0054] figure 1 The welding capillary 110 as a whole is shown in . figure 2 is shown in the magnified figure 1 A diagram of area A is shown.

[0055] Such as figure 1 As shown, a welding capillary (hereinafter, sometimes referred to as “capillary”) 110 has a main body portion 10 . The main body portion 10 is a cylindrical member and has a through hole 20 . The through hole 20 is a through hole extending in the axial direction Da of the main body portion 10 . When using a riving knife, the thread passes through the through hole 20 .

[0056] The body part 10 is provided with: a cylindrical part 11 ; a conical part 12 provided on the front end side of the cylindrical part 11 ; and a bottle neck 13 provided on the front end side of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com