Electric actuator

A technology of electric actuators and electric motors, which is applied in the direction of electric components, transmission devices, electromechanical devices, etc., and can solve problems such as poor movement of electric actuators, abnormal noise, and fixing to the housing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

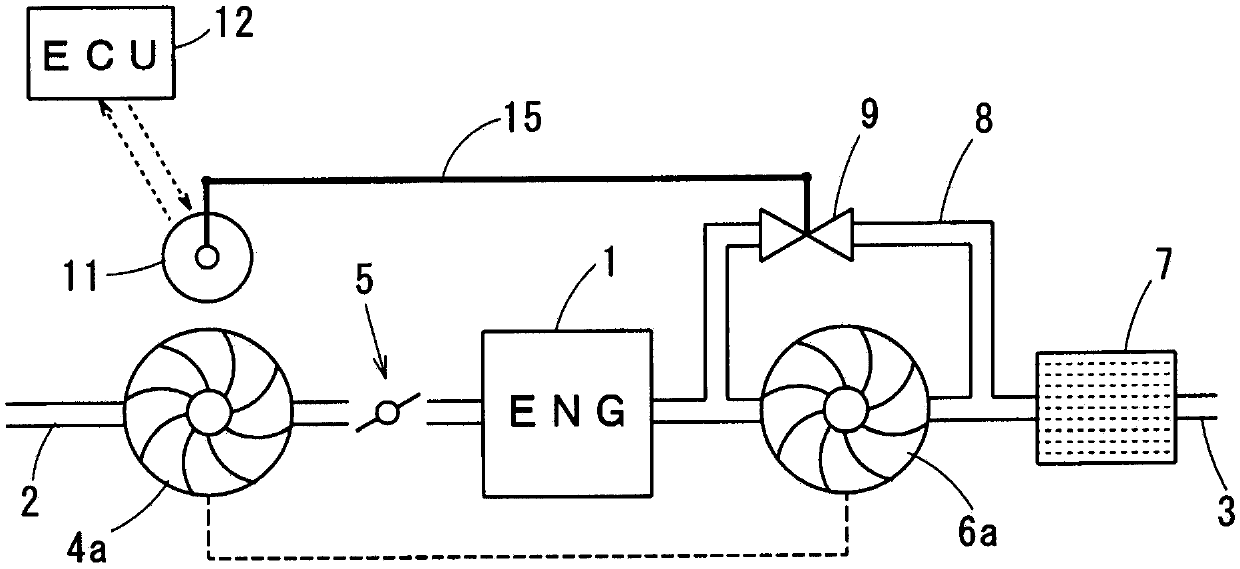

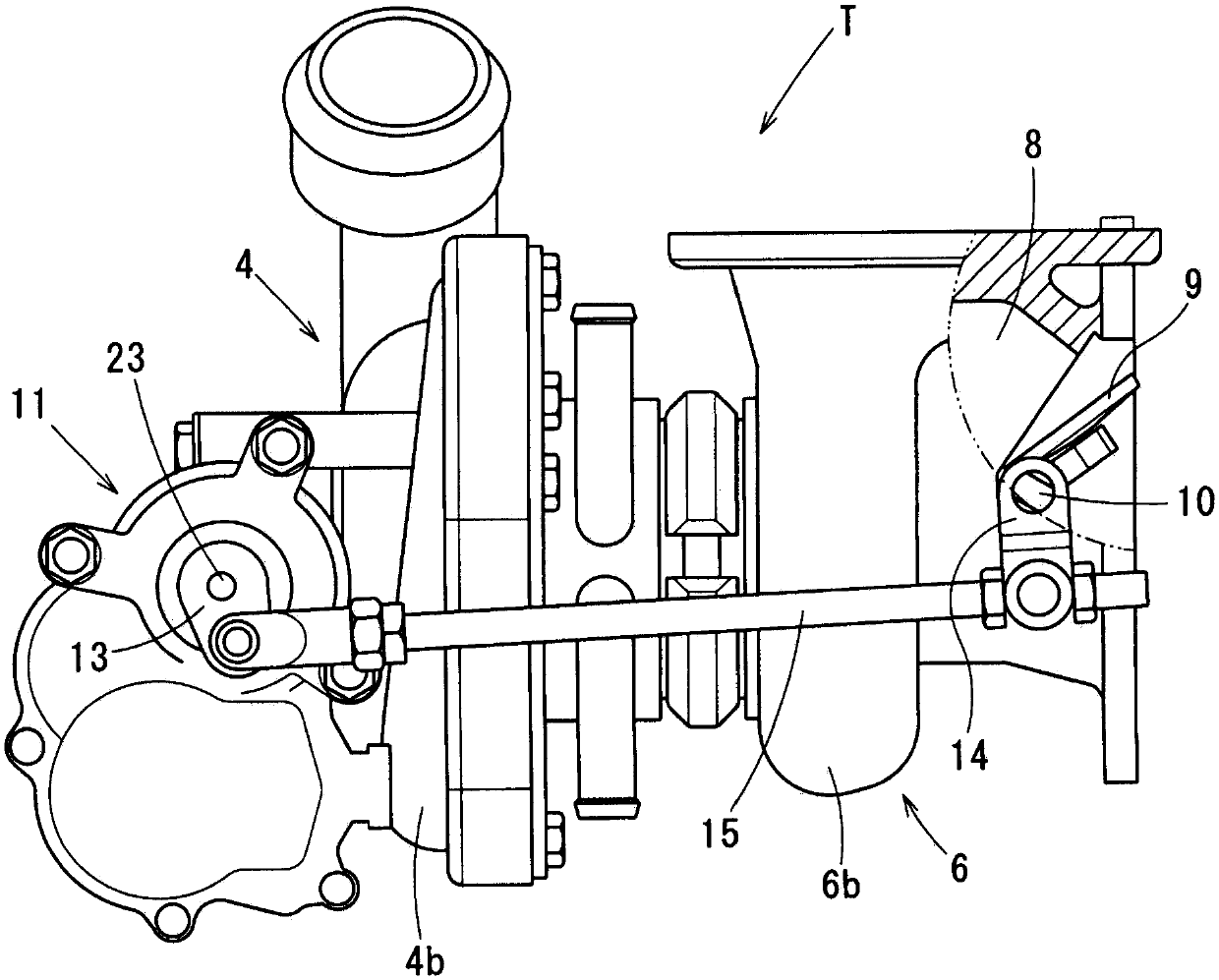

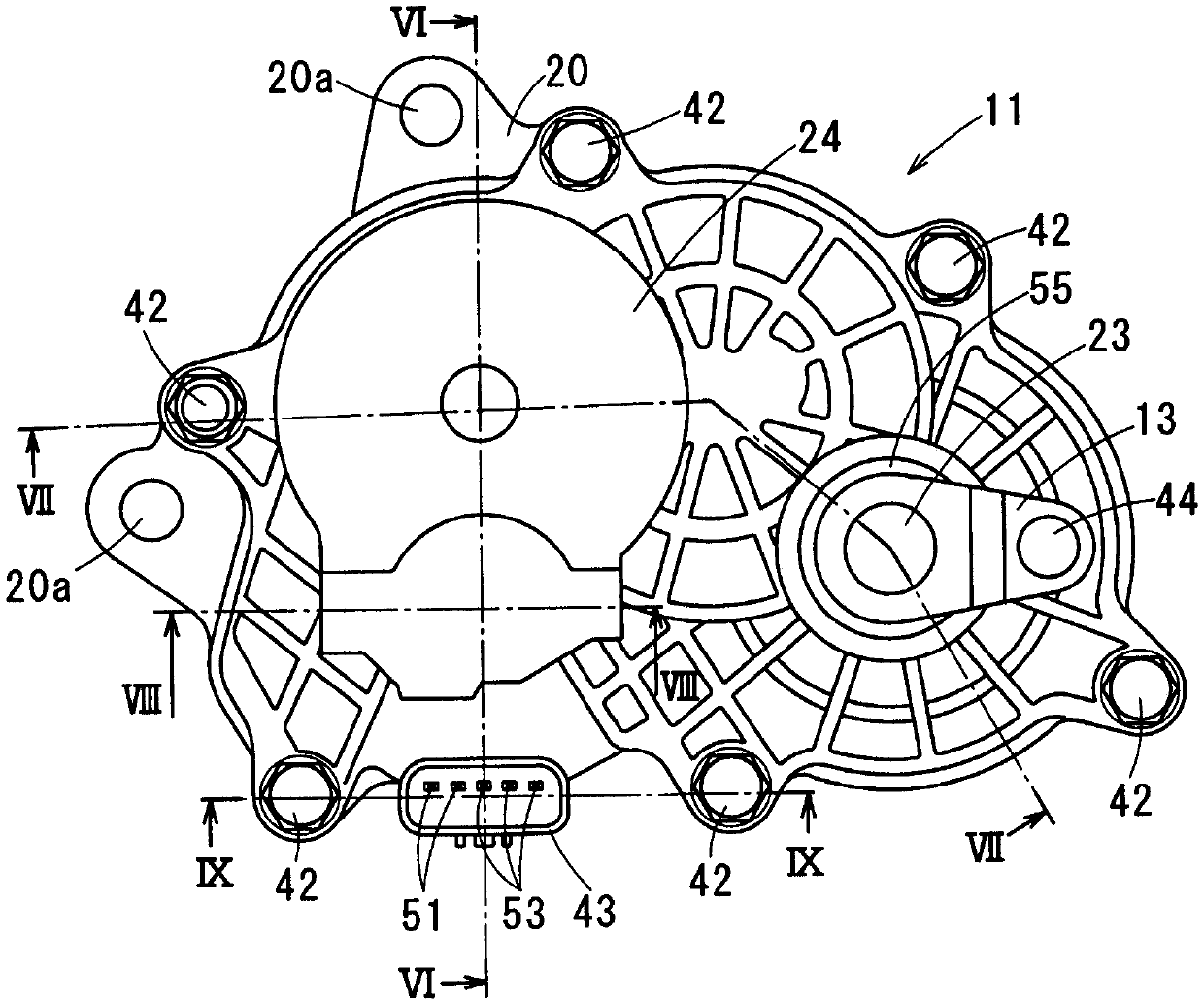

[0032] based on Figure 1 ~ Figure 12C Embodiment 1 will be described.

[0033] An engine 1 for traveling mounted on an automobile is provided with an intake passage 2 for guiding intake air into cylinders of the engine 1 , and an exhaust passage 3 for discharging exhaust gas generated in the cylinders to the atmosphere.

[0034] In the middle of the intake passage 2, an intake compressor 4 of the turbocharger T and a throttle valve 5 for adjusting the amount of intake air supplied to the engine 1 are provided.

[0035] In the middle of the exhaust passage 3, an exhaust turbine 6 of the turbocharger T and a catalyst 7 for purifying exhaust gas are provided. In addition, the catalyst 7 is a well-known three-way catalyst adopting a monolithic structure, and purifies harmful substances contained in the exhaust gas through oxidation and reduction by raising the temperature to the activation temperature.

[0036] The exhaust turbine 6 includes a turbine wheel (turbine wheel) 6a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com