Novel tower-type three-dimensional space vegetable cultivation greenhouse

A three-dimensional space and tower technology, applied in the agricultural field, can solve the problems of unfavorable continuous planting, not using different vegetable planting, inconvenient soil replacement, etc., and achieve the effect of convenient soil replacement, solving the problem of repeated cropping, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

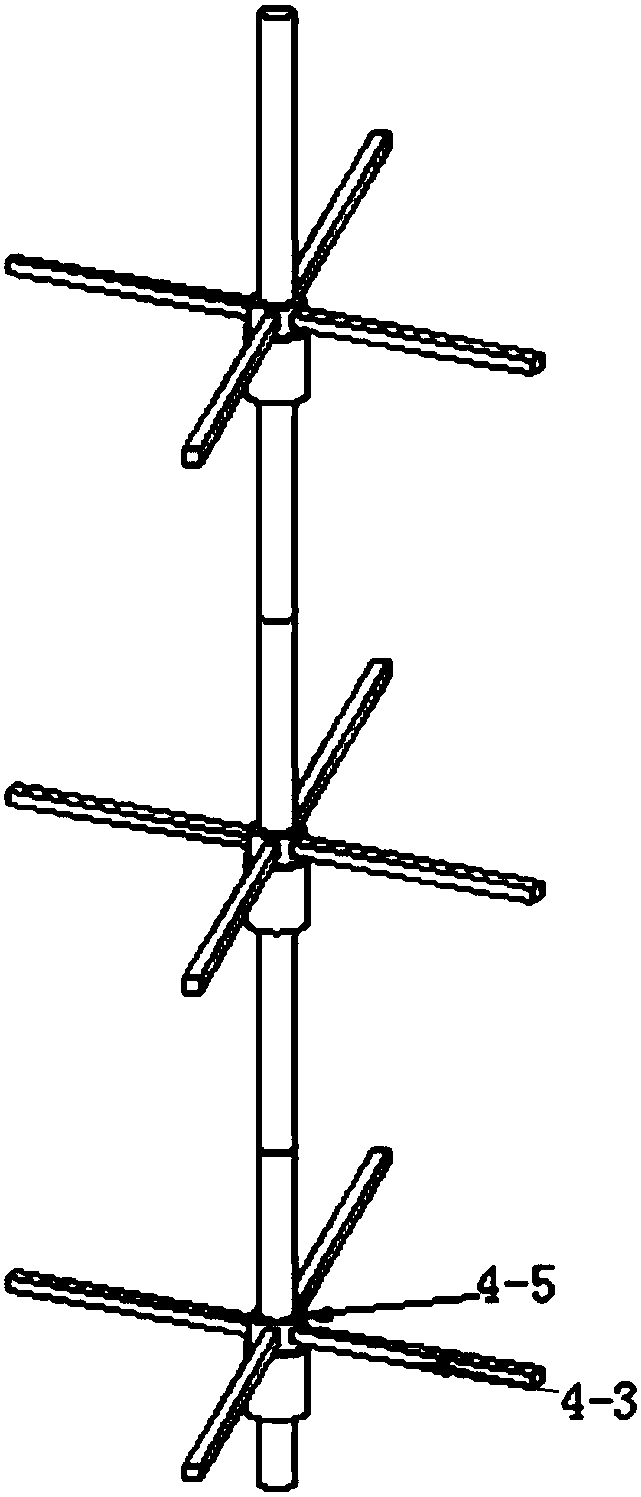

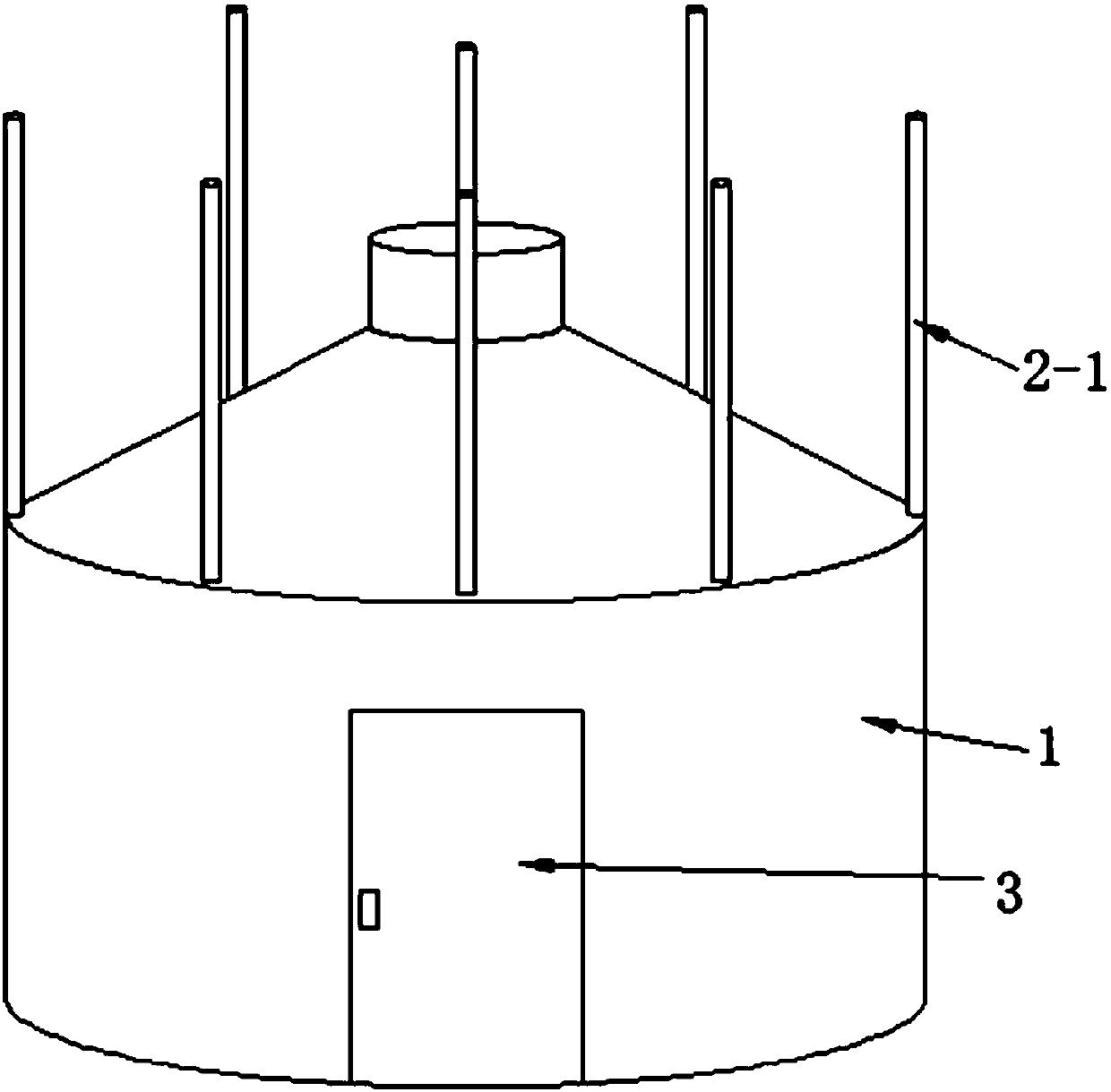

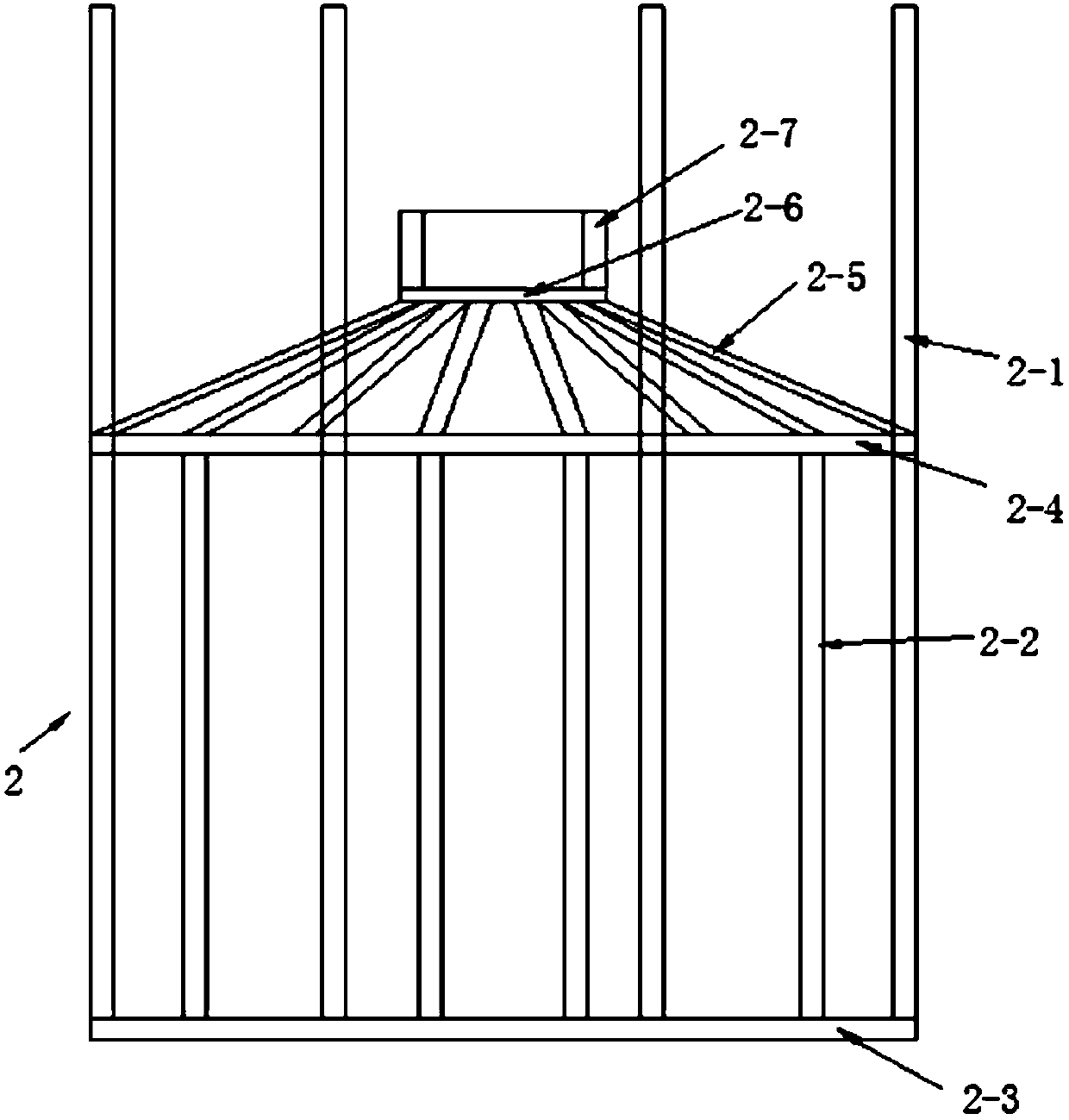

[0023] see as Figure 1-Figure 8 As shown, the technical solution adopted in this specific embodiment is: it includes the thermal insulation outer layer 1, the steel frame 2, the planting mechanism 4 and the sprinkler mechanism 5; the thermal insulation outer layer 1 is wrapped on the outside of the steel frame 2, and is fixed by steel wire On the steel frame 2, the two constitute a planting shed body with an open top, and an access door 3 is provided on the front side of the planting shed body; bedding insulation material); the several planting mechanisms 4 are arranged inside the steel frame 2, and the sprinkler mechanism 5 is arranged on the inner top of the steel frame 2; the planting mechanism 4 is composed of a support rod 4-1 and a planting tray 4-2 , support frame 4-3, support sleeve 4-4, collar 4-5 and limit sleeve 4-6; the lower end of the support rod 4-1 is inserted and fixed on the ground, and its upper end is welded and fixed on the steel frame 2 above; the exter...

specific Embodiment approach 2

[0029] see Figure 9 The difference between this specific embodiment and specific embodiment 1 is that: several lower water delivery pipes 5-5 are connected to the bottoms of the several annular pipes 5-3, and the lower water delivery pipes 5-5 are passed through metal universal pipes. 5-6 is connected with the sprinkler head 5-7 on the lower floor, and the rest of the components and connection relationship are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com