Rice washing and cooking all-in-one machine

An all-in-one machine and rice storage technology, which is applied to the structure of cooking utensils, cooking utensils, household appliances, etc., can solve the problems of large water consumption, high cost, and time-consuming, and achieve smooth water flow, improve quality, and reduce water consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

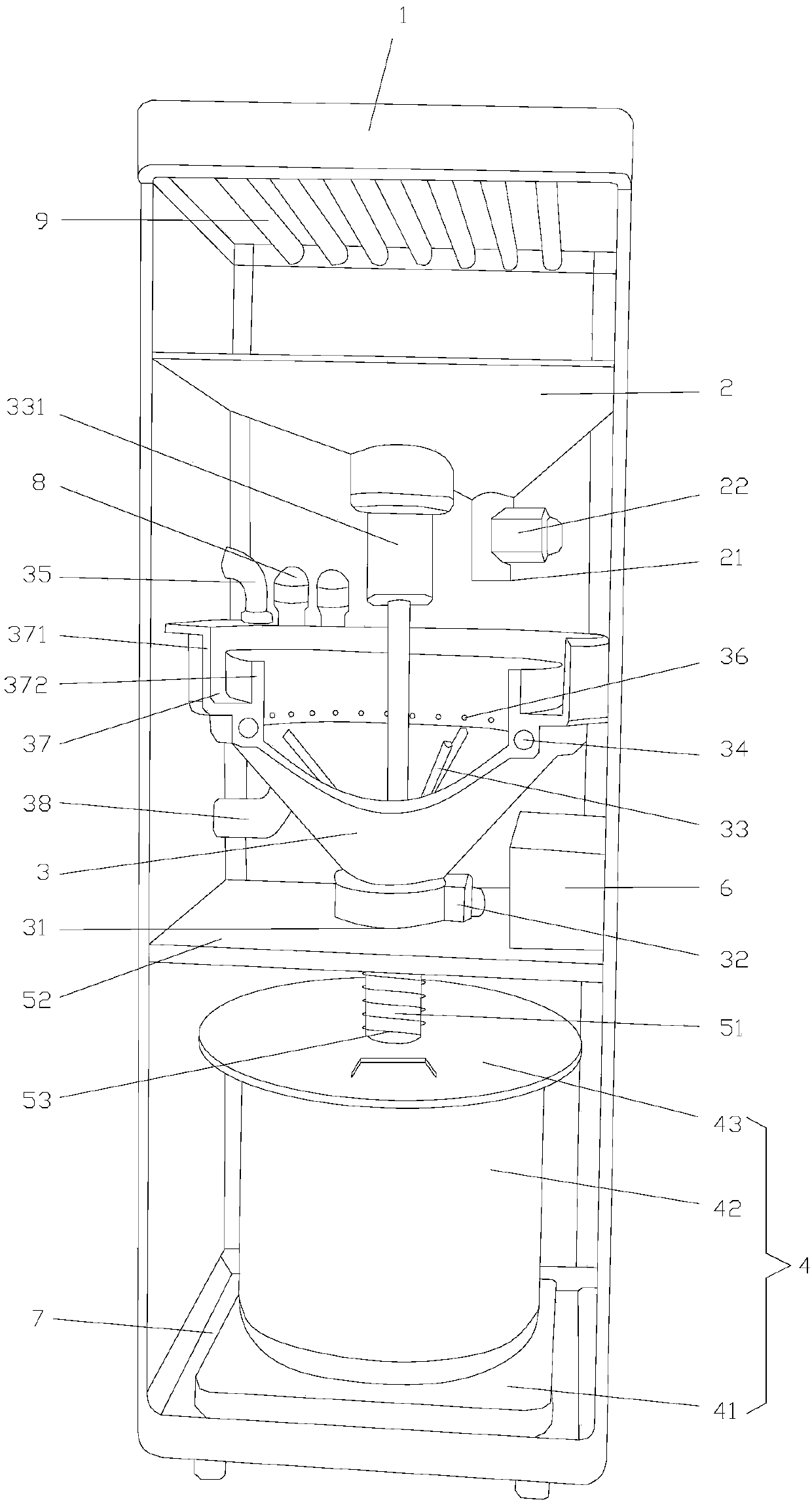

[0023] Embodiment 1 provides a kind of all-in-one machine for washing rice and cooking rice, such as figure 1 As shown, it includes a housing 1 and a rice storage hopper 2, a rice washing bucket 3 and an electric rice cooker 4 installed in the housing 1 from top to bottom in sequence. The bottom of the rice storage hopper 2 is provided with a first rice leakage port 21 and for The first valve 22 that controls the opening and closing of the first rice leakage port 21, the first valve 22 is preferably a solenoid valve, the rice grains in the rice storage bucket 2 enter the rice cleaning bucket 3 below it through the first rice leakage port 21, and the The bottom of the rice hopper 3 is provided with a second rice leakage port 31 and a second valve 32 for controlling the opening and closing of the second rice leakage port 31. The second valve 32 is preferably a solenoid valve, and the rice grains in the rice cleaning hopper 3 pass through the second valve 32. Two rice leakage mou...

Embodiment 2

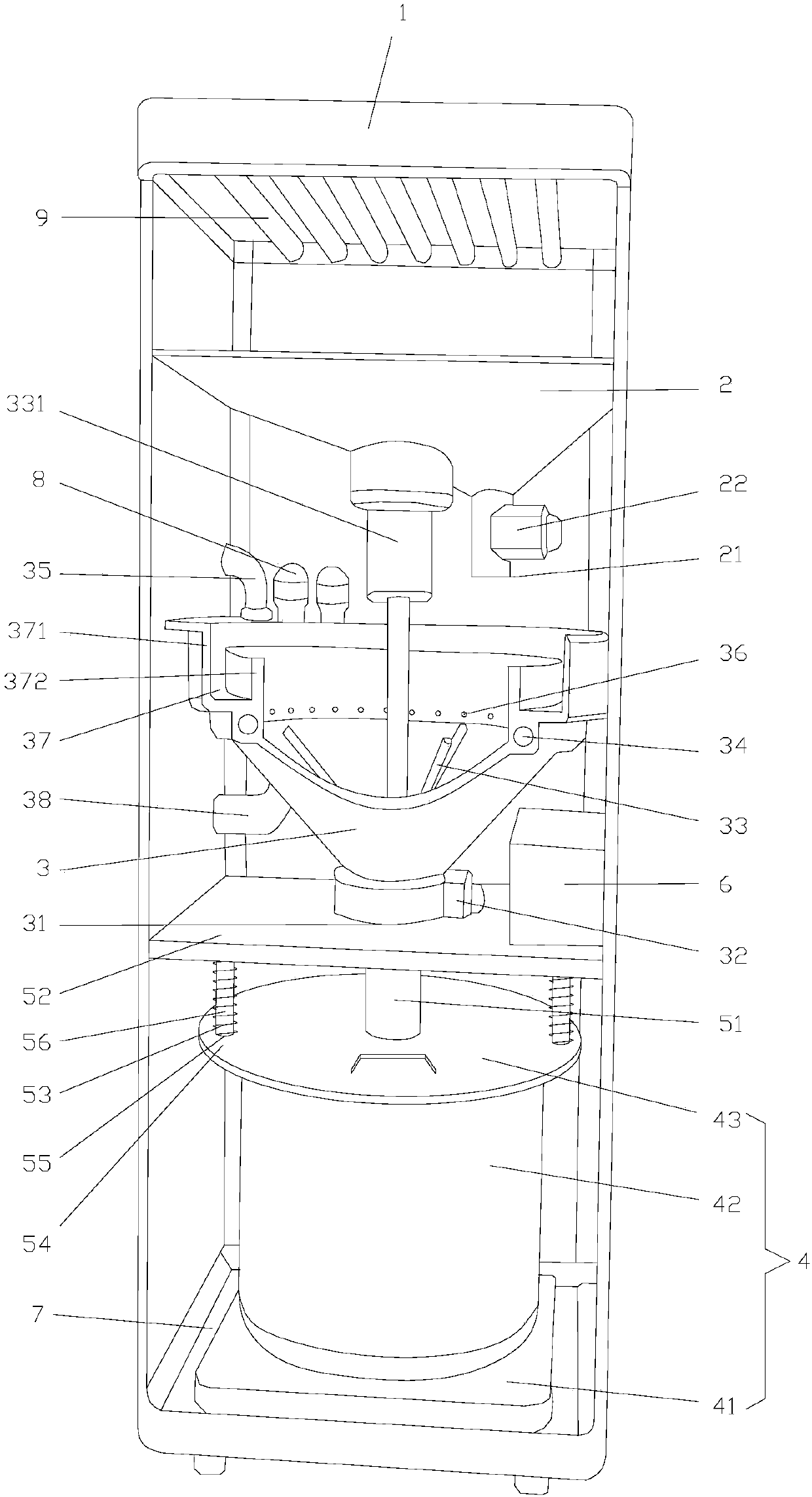

[0031] Embodiment 2 provides a kind of all-in-one machine for washing rice and cooking rice, such as figure 2 As shown, the components included in Embodiment 2 and the relationship between each component are basically the same as Embodiment 1, the difference is that the outer edge of the pot cover 43 is provided with a pressing portion that exceeds the pot mouth of the pot body 42 54, a guide hole 55 is provided on the pressing part 54, a guide rod 56 extending downward and passing through the guide hole 55 is connected on the diaphragm 52, the pot cover 43 can translate up and down along the guide rod 56, and the compression spring 53 is sleeved On the guide rod 56, and the two ends of the compression spring 53 are respectively supported on the diaphragm 52 and the pressing part 54, like this, the pressing part 54 of the pressing pot cover 43 is pressed down by the compression spring 53 so that the pot cover 43 is covered tightly, When uncovering the pot cover 43, the pot co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com