Oil groove filter screen for cutting fluid used for machine tool

A filter and cutting fluid technology, applied in the direction of filtration separation, fixed filter element filter, separation method, etc., can solve the problems of inconvenient use, troublesome filter installation and disassembly, and no good solution, etc., to achieve good filtering effect , good practicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

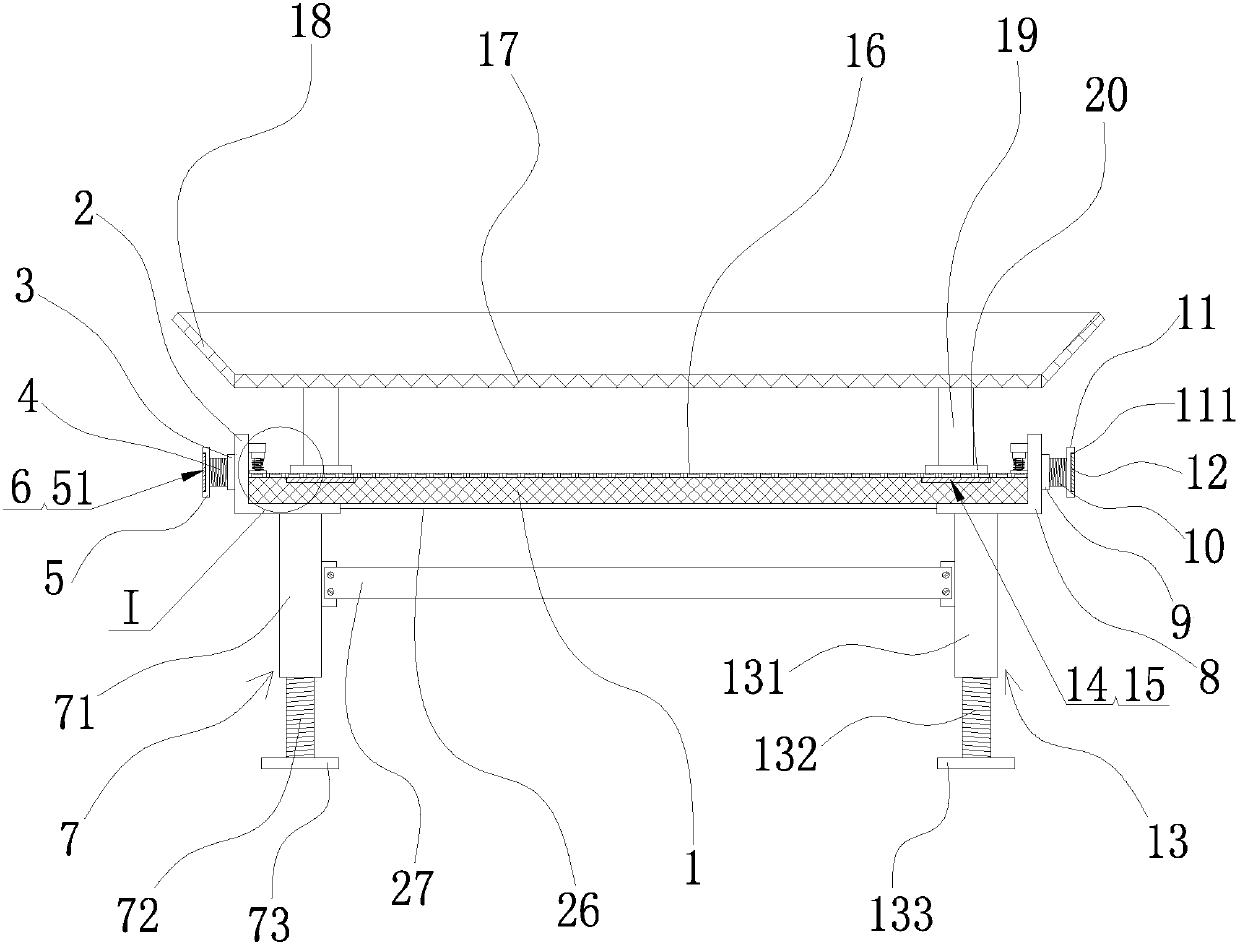

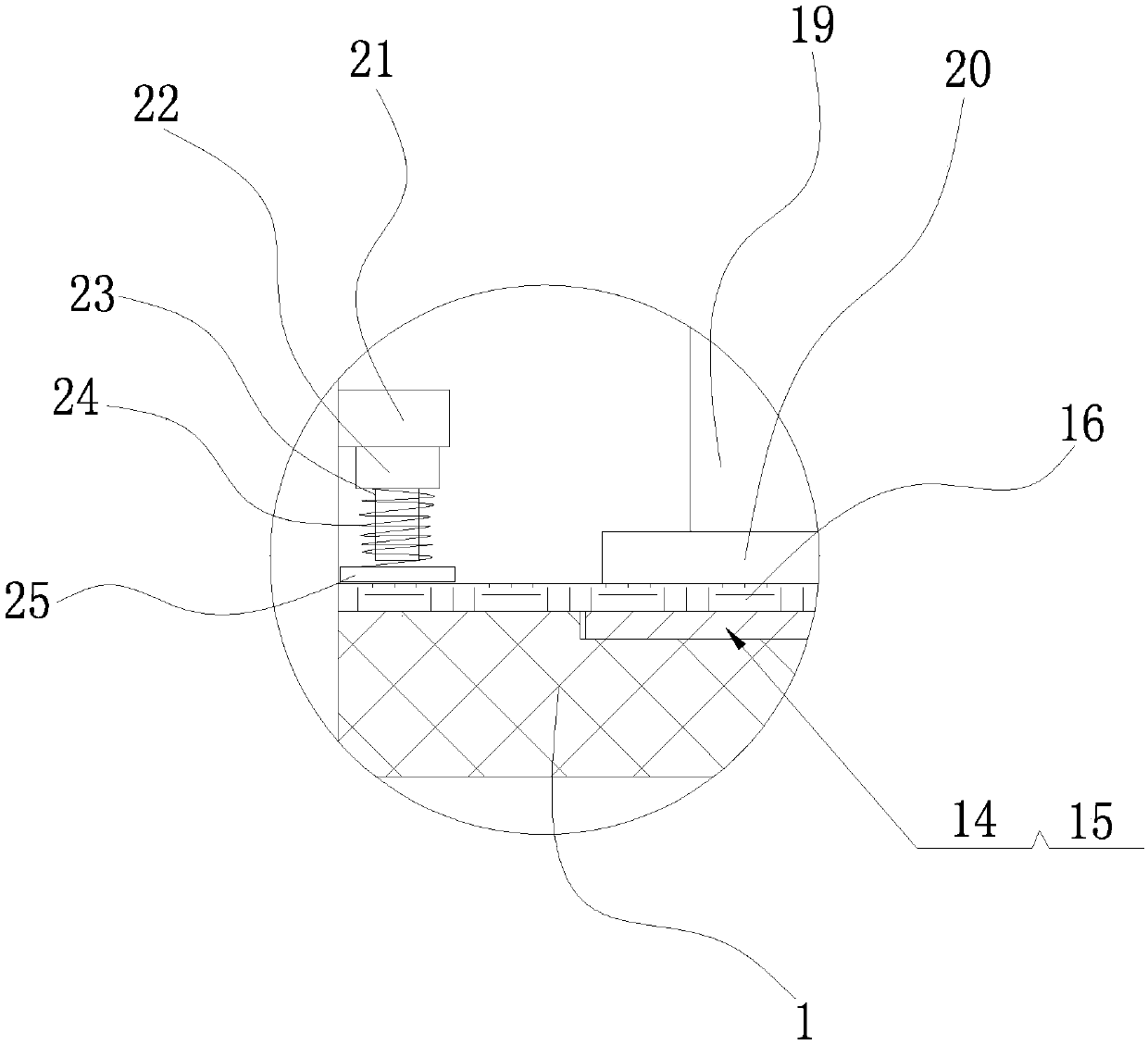

[0026] Example: such as figure 1 with figure 2 As shown, a cutting fluid oil tank filter screen for machine tools includes a filter screen body 1, a first positioning bracket 2 is welded on the left end of the filter screen body 1, and a first positioning bracket 2 is welded on the left end surface of the first positioning bracket 2. A positioning nut 3, the nut hole internal thread of the first positioning nut 3 is connected with a first adjusting screw 4, the left end of the first adjusting screw 4 is welded with a first positioning plate 5, the first positioning plate 5 is provided with a first storage groove 51 on the left end surface of the first storage groove 51, and a first magnet 6 is embedded in the first storage groove 51, and the first magnet 6 is glued to the inner wall surface of the first storage groove 51. connected and fixed; the lower end of the first positioning bracket 2 is provided with a left supporting foot 7; the right end of the filter body 1 is weld...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap