A method for rapid synthesis of mesoporous biporous zif-8 materials at room temperature

A technology of ZIF-8, medium and micro-holes, applied in chemical instruments and methods, alkali metal compounds, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of restricting the entry of macromolecules, interpenetration, and rapid collapse and other issues, to achieve the effect of mild conditions, energy saving and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Dissolve 0.285g of zinc oxide in 5mL of deionized water and stir for 20 minutes to obtain a zinc oxide solution; dissolve 1.097g of zinc acetate dihydrate in 5mL of deionized water and stir for 10 minutes to obtain a zinc acetate solution; Dimethylimidazole was dissolved in 5mL N,N-dimethylformamide, and stirred for 10 minutes to obtain 2-methylimidazole solution; the zinc oxide solution was mixed with zinc acetate solution, and stirred for 20 minutes to obtain a mixed solution of zinc oxide and zinc acetate ; Add 2-methylimidazole solution and 1.07g hexadecane bromide to the mixed solution of zinc oxide and zinc acetate, and stir for 20 minutes; Suction filter the resulting product, put it into a vacuum oven at 110°C and dry it for 10 hours, The obtained medium and micro biporous ZIF-8 material is marked as sample A.

Embodiment 2

[0036] Dissolve 0.296g of zinc oxide in 5mL of deionized water and stir for 30 minutes to obtain a zinc oxide solution; dissolve 1.097g of zinc acetate dihydrate in 5mL of deionized water and stir for 20 minutes to obtain a zinc acetate solution; Dissolve imidazole in 5mL N,N-dimethylformamide, stir for 20 minutes to obtain 2-methylimidazole solution; mix zinc oxide solution and zinc acetate solution, and stir for 30 minutes to obtain a mixed solution of zinc oxide and zinc acetate; Add 2-methylimidazole solution and 1.11 g of hexadecane bromide to the mixed solution of zinc oxide and zinc acetate, and stir for 30 minutes; filter the resulting product with suction, and dry it in a vacuum oven at 120°C for 12 hours to obtain A mesomicro biporous ZIF-8 material, marked as sample B.

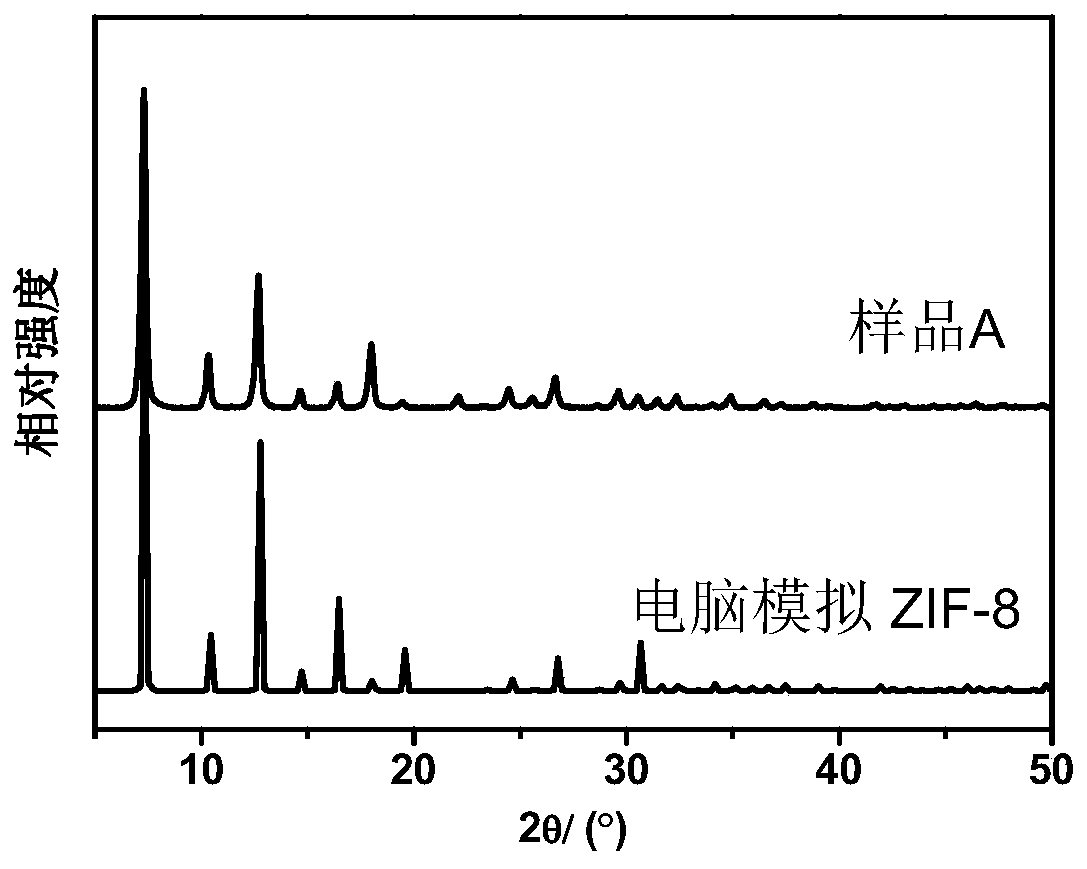

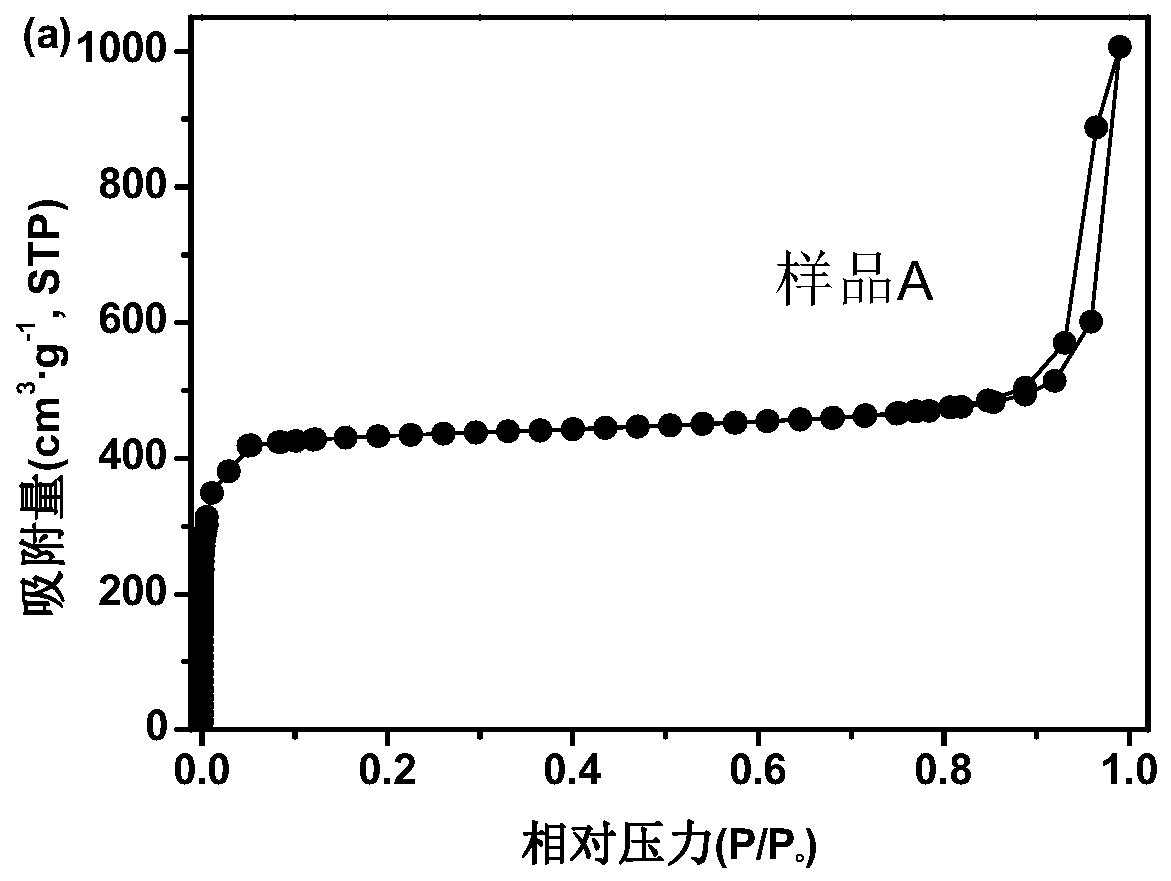

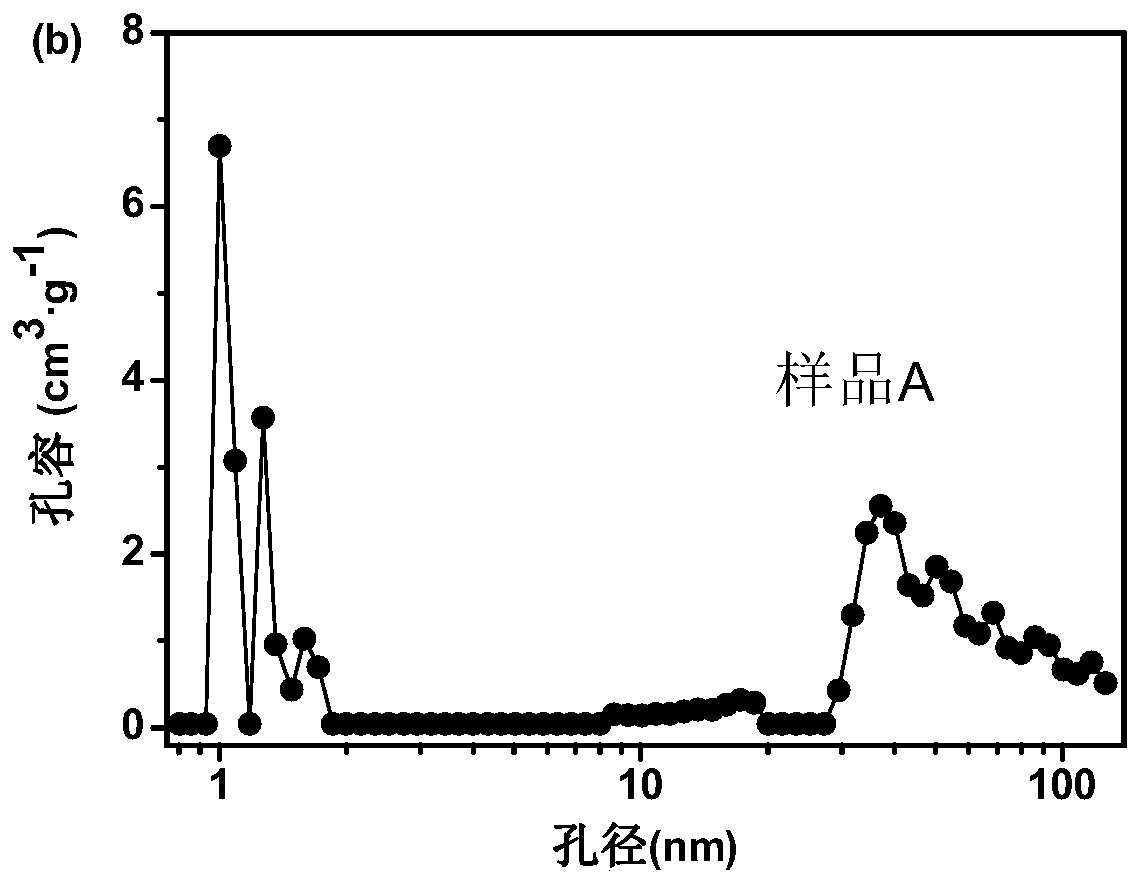

[0037] The medium-micro-double-porous ZIF-8 material prepared in Example 1 was used as a representative for analysis. The analysis results of the medium-micro-double-porous ZIF-8 material prepared i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com