Cleaning device for air purification

A cleaning device and air purification technology, applied in electrode cleaning, external electrostatic separator, electrostatic separation, etc., can solve the problems of manual maintenance, PM2.5 pollution, human health hazards, etc., to reduce occupation and reduce the entry of garbage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

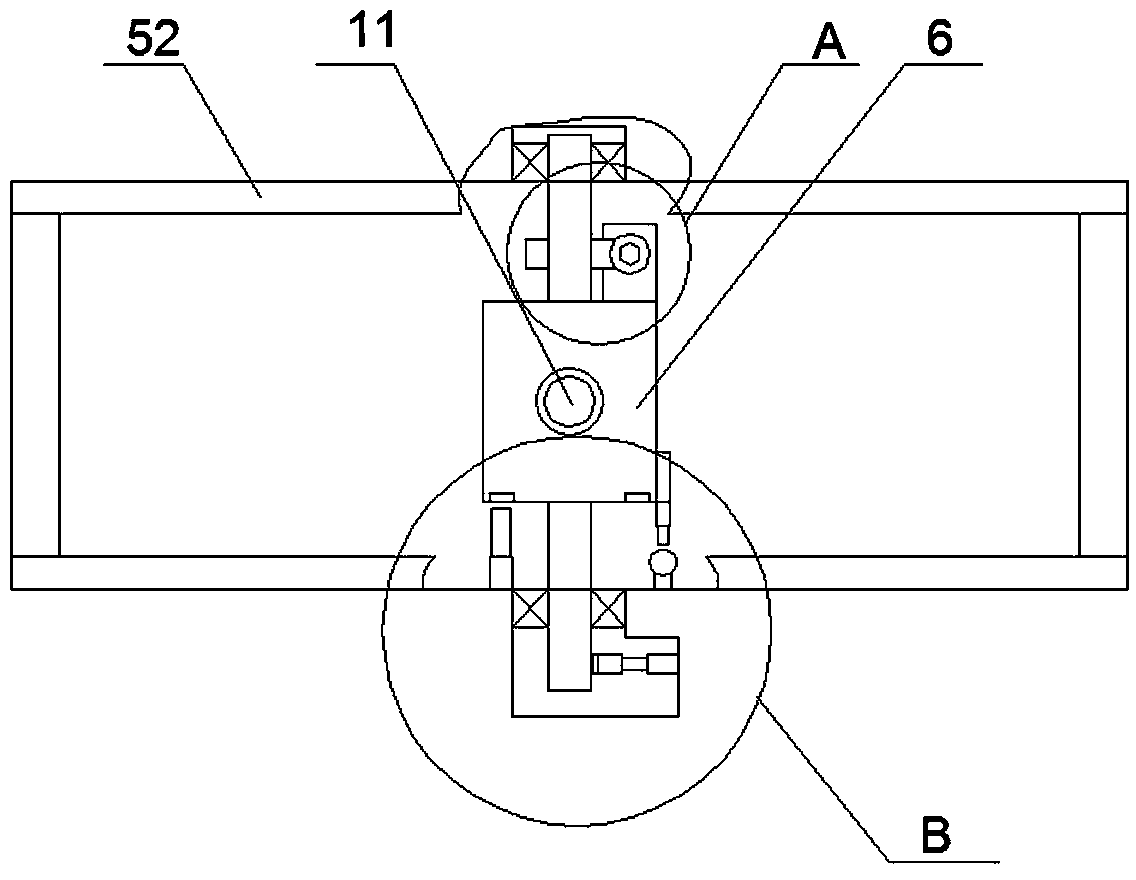

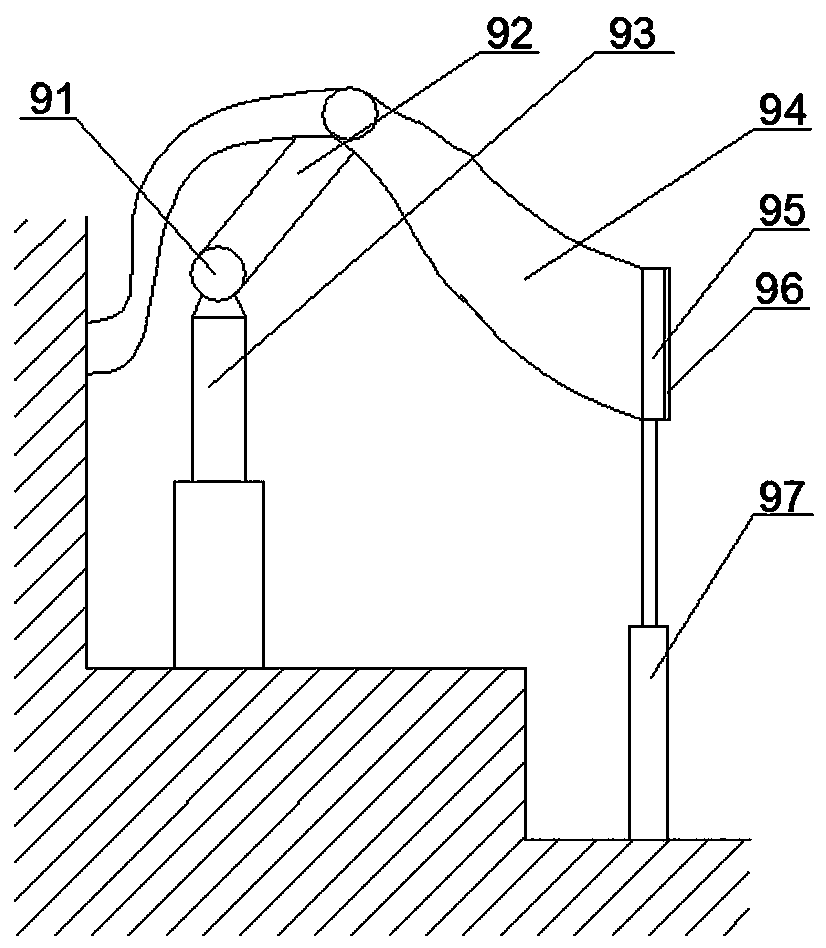

[0052] A cleaning device for air purification, comprising a tank body 1, a haze removal mechanism arranged in the tank body 1 for removing haze, and a regeneration device that is arranged in the tank body 1 and cooperates with the haze removal mechanism Mechanism 9, the opening and closing mechanism arranged at the opening of the tank body 1 for opening and closing, the sewage discharge mechanism arranged at the bottom of the tank body 1, the driving mechanism arranged in the tank body 1, and the 1 The control mechanism on the side wall is used to coordinate and control the haze removal mechanism, the regeneration mechanism 9, the opening and closing mechanism 5 and the sewage mechanism;

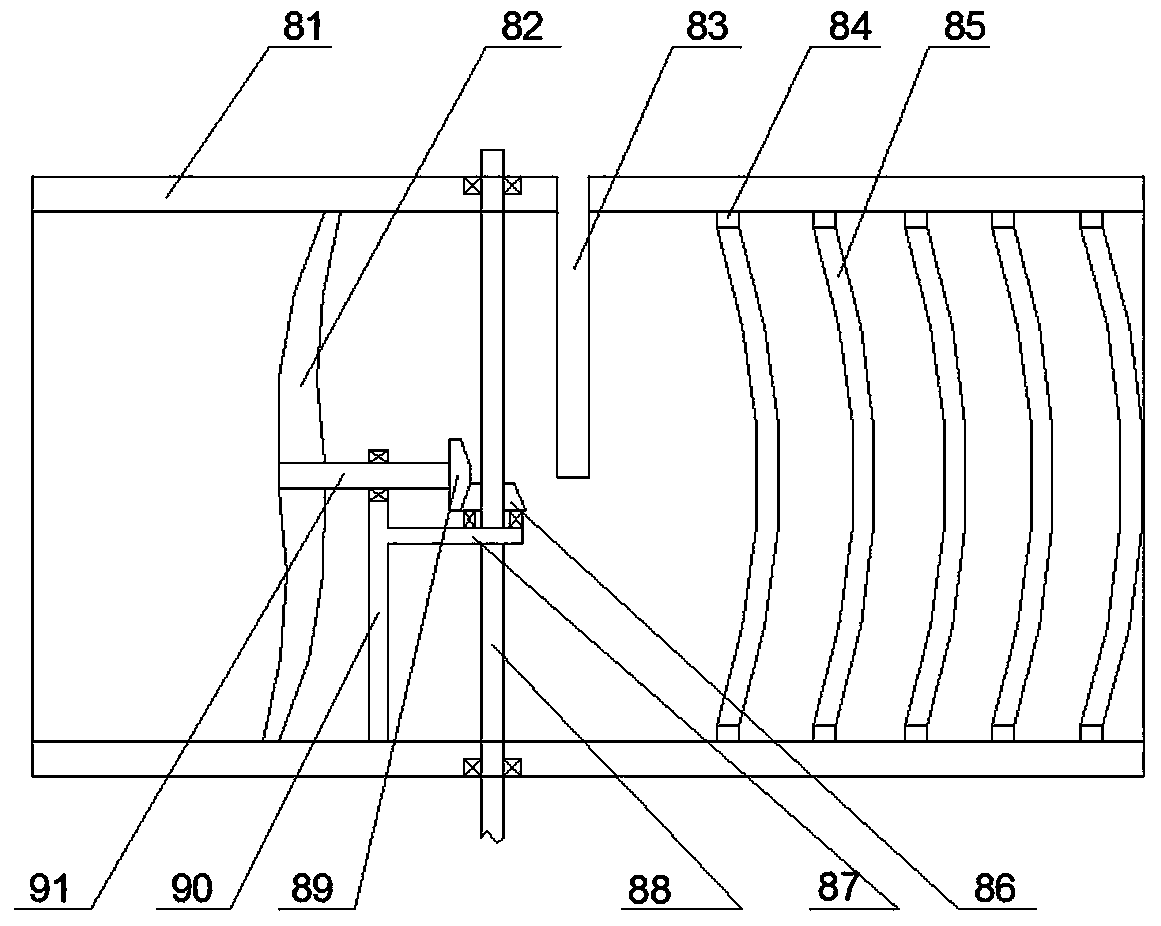

[0053] The haze removal mechanism includes a rotating module arranged on the tank body, two haze removal telescopic rods arranged on the rotation module, and a haze removal module 8 arranged at the ends of the haze removal telescopic rods 11, arranged in the groove A locking module on the si...

Embodiment 2

[0073] The difference from Embodiment 1 is that the vertical transmission rod 88 is a hexagonal rod.

[0074] In this embodiment, in order to ensure the operation of the device, an electrostatic protection net is set on each telescopic element and the weak current element to ensure the stable operation of the device, and the components used are all treated with antirust to avoid corrosion caused by long-term underground; and The vertical transmission rod used is a hexagonal rod, which can ensure the stability of power transmission. In order to ensure that the hexagonal rod can move freely up and down in the first bevel gear when the haze removal telescopic rod is stretched, graphite lubrication is installed on the surface of the hexagonal rod. layer or lubricating oil.

[0075] In addition, the stirring hose used in this embodiment is made of elastic rubber and has a trumpet shape, which can ensure a good bridge with the haze removal tube and a perfect connection with the brid...

Embodiment 3

[0077] Such as Figure 10 Shown, its difference with embodiment two is:

[0078] The second rotating member 72 is a worm, and the third transmission member 73 is a worm wheel.

[0079] The middle part of the spacer rod 57 is provided with a first slot 58 and a second slot 59 that match the haze removal telescopic rod 11 and the vertical transmission rod 88;

[0080] An elastic film disposed on the first slot 58 and the second slot 59 .

[0081] The second rotating part used in this embodiment is a worm, and the third rotating part used is a worm wheel, which can convert the horizontally arranged power into vertical power, and can be rotated by the output shaft after the motor casing is locked. , to transmit the power to the vertical transmission parts, and can drive the lower haze removal impeller to work during the regeneration process, so as to stir the air in the tank and ensure that the humidity in the tank will not be too high; at the same time, due to the The transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com