Copper bar cutting-off machine with automatic collecting mechanism

A technology of cutting machine and cutting mechanism, which is applied to the feeding device, positioning device, storage device, etc., can solve the problems of small adjustment range of cutting length, damage and deformation of copper rods, and difficult to move, so as to avoid scatter and improve the The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

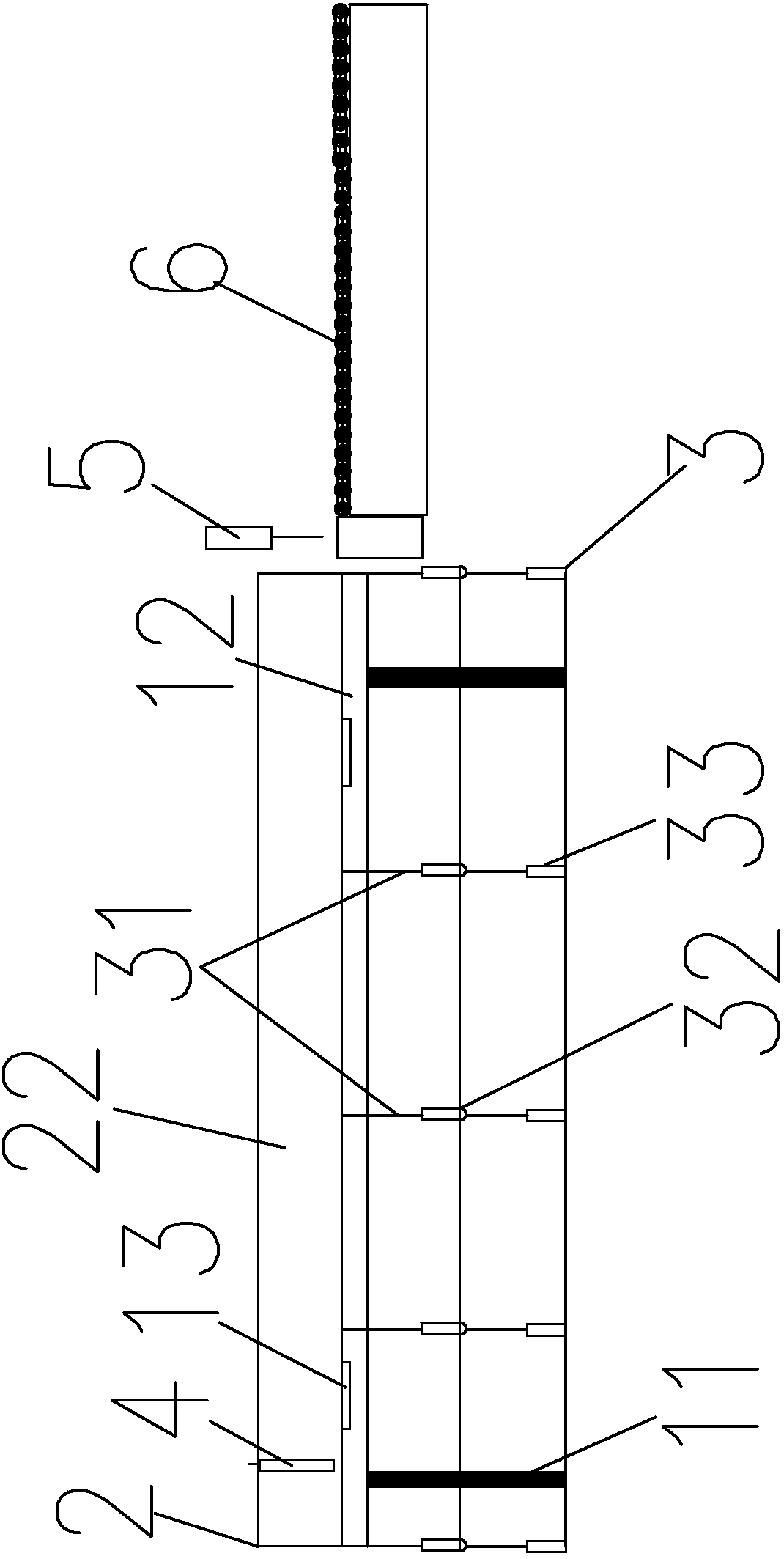

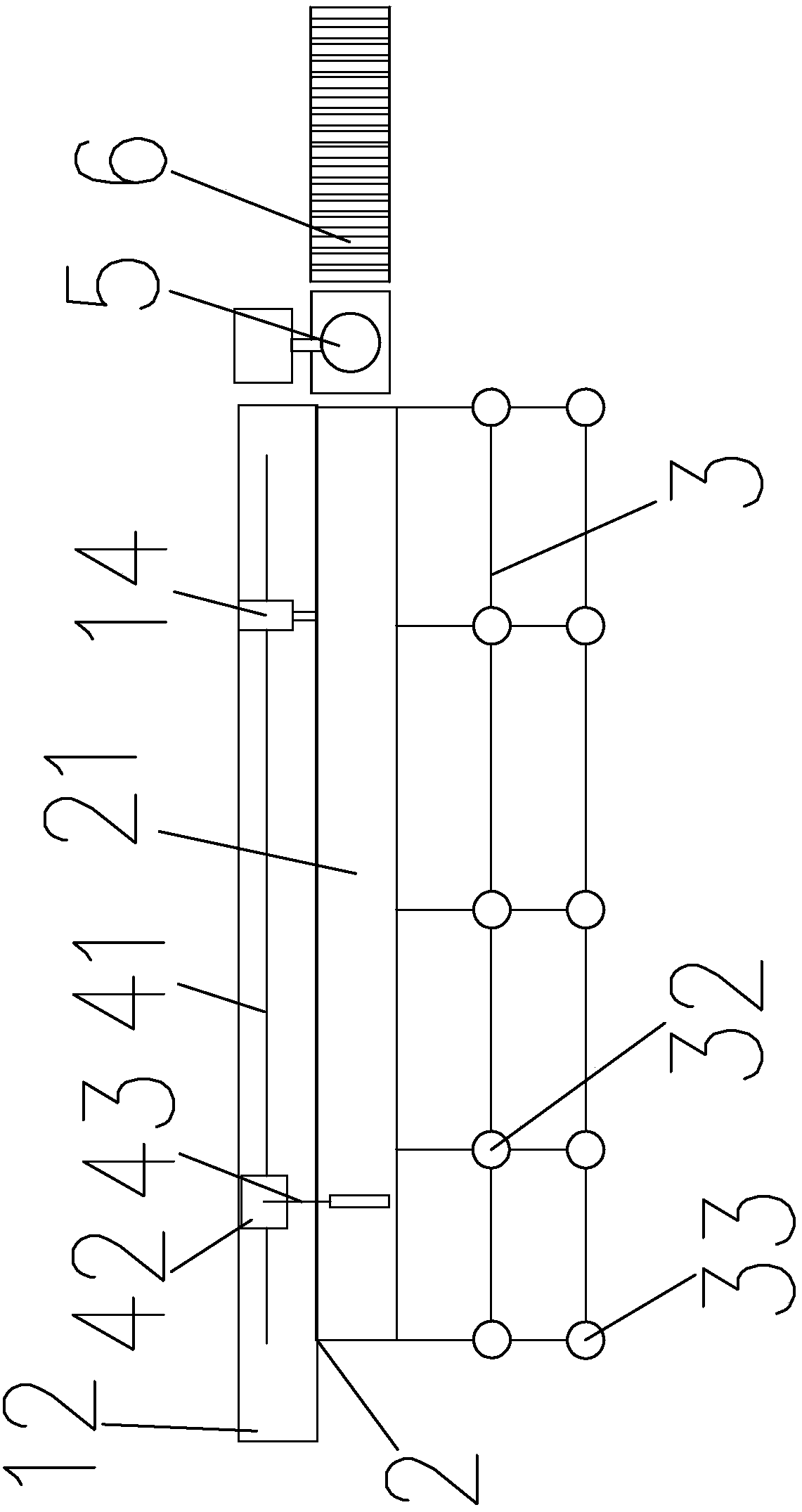

[0017] refer to figure 1 and figure 2 , a kind of copper rod cutting machine with automatic collecting mechanism of the present invention, comprises control system, air cylinder 14, conveyer belt 6, cutting mechanism 5, long table 1 and the collecting frame 3 that is arranged on the side of long table 1, described cutting Mechanism 5 is a high-speed punching machine, and the high-speed punching machine is provided with a sharp punching head, which can realize precise cutting of copper rods. The long table 1 includes four supporting legs 11 and a rectangular table top 12, the table top 12 is provided with a right-angled long groove 2 parallel to the rectangular table top 12, and the right-angled long groove 2 includes a vertical surface 22 and a horizontal surface 21, the vertical surface 22 and the horizontal surface 21 are welded at 90°, the horizontal surface 21 of the right-angled long groove 2 is wider than the vertical surface 22, and the outside of the right-angled lon...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap