Screw feeding device of screw driving robot

A robot and screw locking technology, which is applied to screwdrivers, wrenches, manufacturing tools, etc., can solve the problems of low screw conveying efficiency, low screw locking efficiency, easy material jams, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0020] One of the implementation manners: the vacuum valve is connected with a pumping dual-purpose vacuum pump. Another embodiment: the vacuum valve is respectively connected with a micro air pump and a micro air pump.

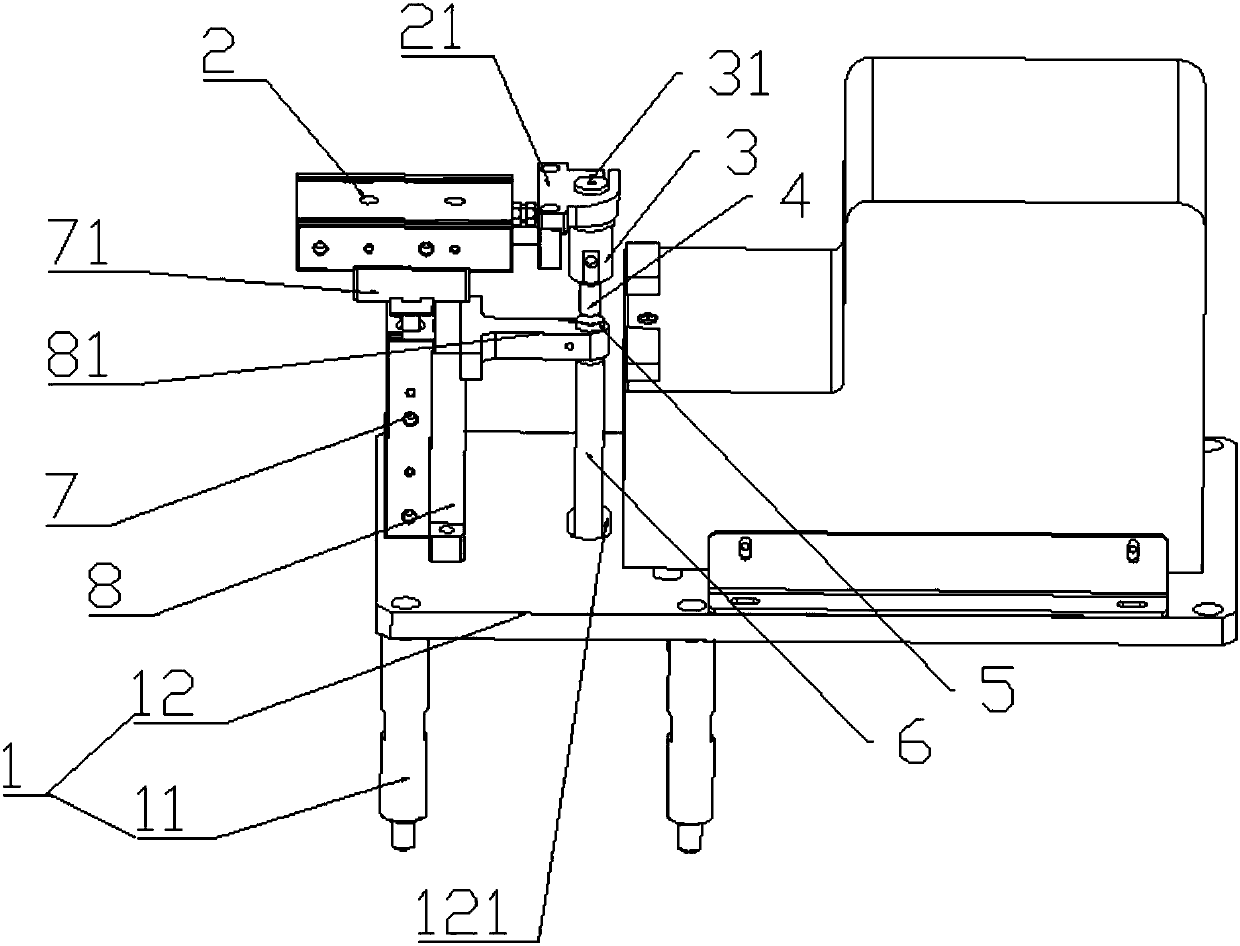

[0021] Also includes a fixed seat 8, the Z-axis cylinder 7 is fixed on the fixed seat 8, the fixed seat 8 is provided with a limit block 81, and the blowing nozzle 5 is fixed on the limit block 81 Above, the air blowing pipe 6 is tightly connected to the air blowing nozzle 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com