Pug mill

A technology of mud refining machine and frame, which is applied in the directions of clay preparation device, mixing operation control device, unloading device, etc., to achieve the effect of ensuring production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

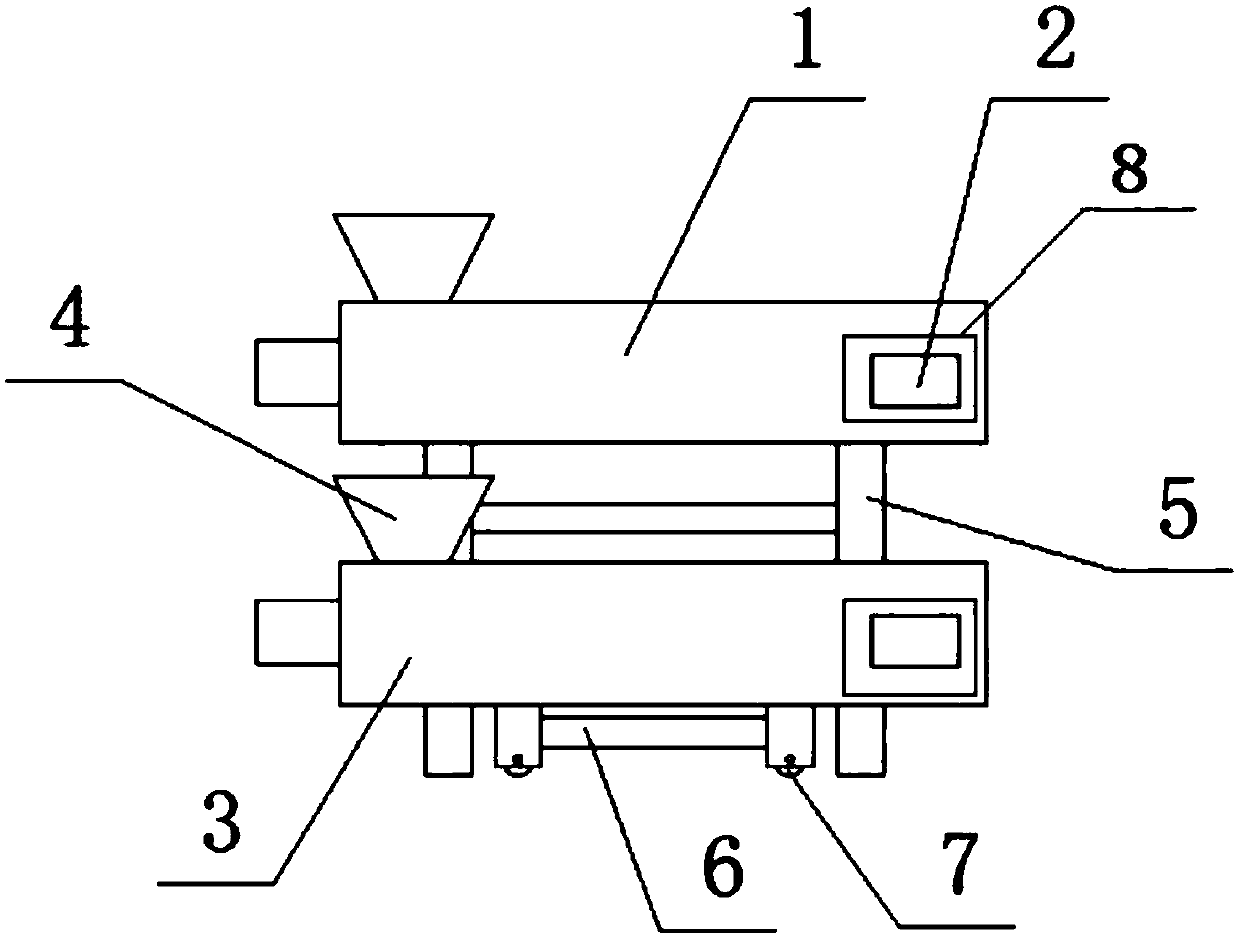

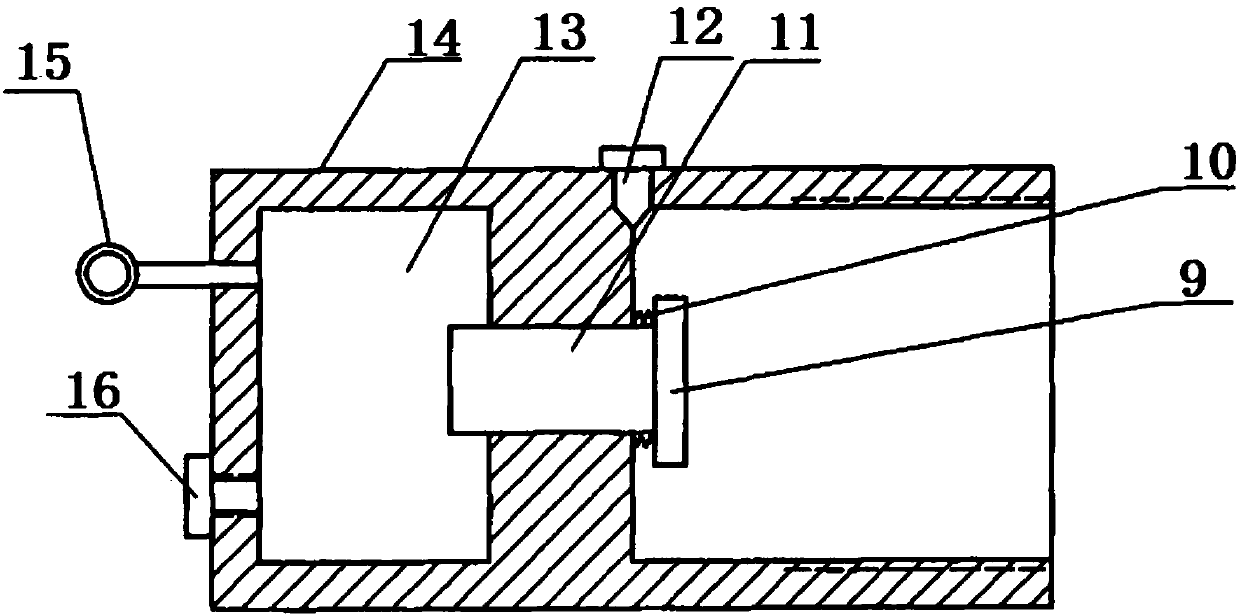

[0030] exist figure 1 , In the embodiment shown in 2, the present invention includes the first mud refining machine 1, the discharge port 2, the second mud refining machine 3, the feeding port 4, the first frame 5, the second frame 6, the roller 7, Extrusion force tester 8, pressure head 9, rubber sleeve 10, piston 11, vent hole 12, oil tank 13, cylindrical shell 14, oil pressure gauge 15, oil seal cover 16.

[0031] The first mud refining machine 1 is fixedly arranged on the frame, and the first mud refining machine 1 is provided with two discharge ports 2, and each discharge port is provided with an extrusion force measuring instrument 8. The extrusion force measuring instrument 8 comprises a pressure head 9, a rubber sleeve 10, a piston 11, an air vent 12, an oil tank 13, a cylindrical shell 14, an oil pressure gauge 15 and an oil seal 16; The way of moving left and right is arranged on the frame, and the frame includes a first frame 5 and a second frame 6, the first frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com