Ultrasonic plasticizing forming system and forming method

An ultrasonic and ultrasonic technology, applied in the field of ultrasonic plasticizing molding system, can solve the problems that ultrasonic plasticizing molding products cannot meet the quality requirements, can not effectively control the polymer plasticizing time, plasticizing quality, plasticizing quality decline, etc., to achieve Saving raw materials, strong practicability, and the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

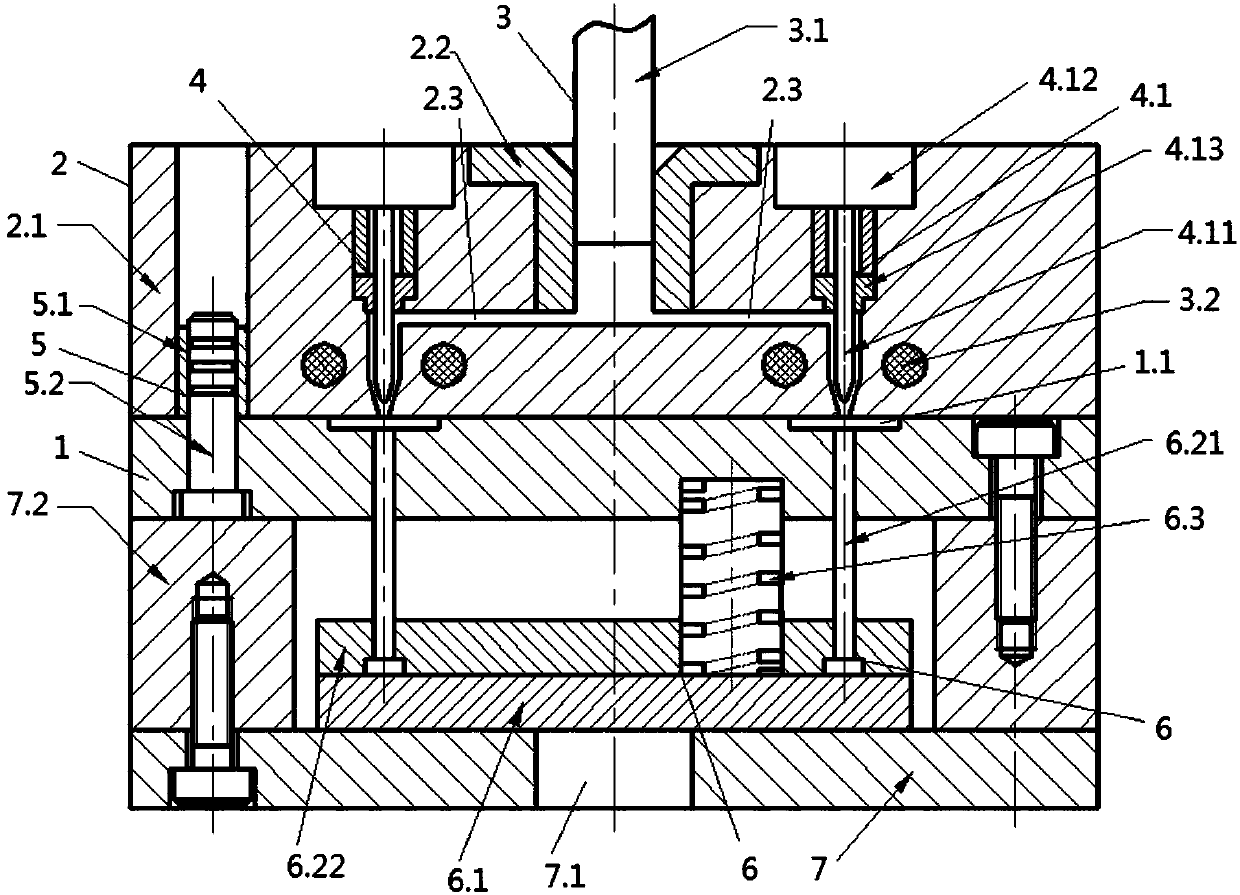

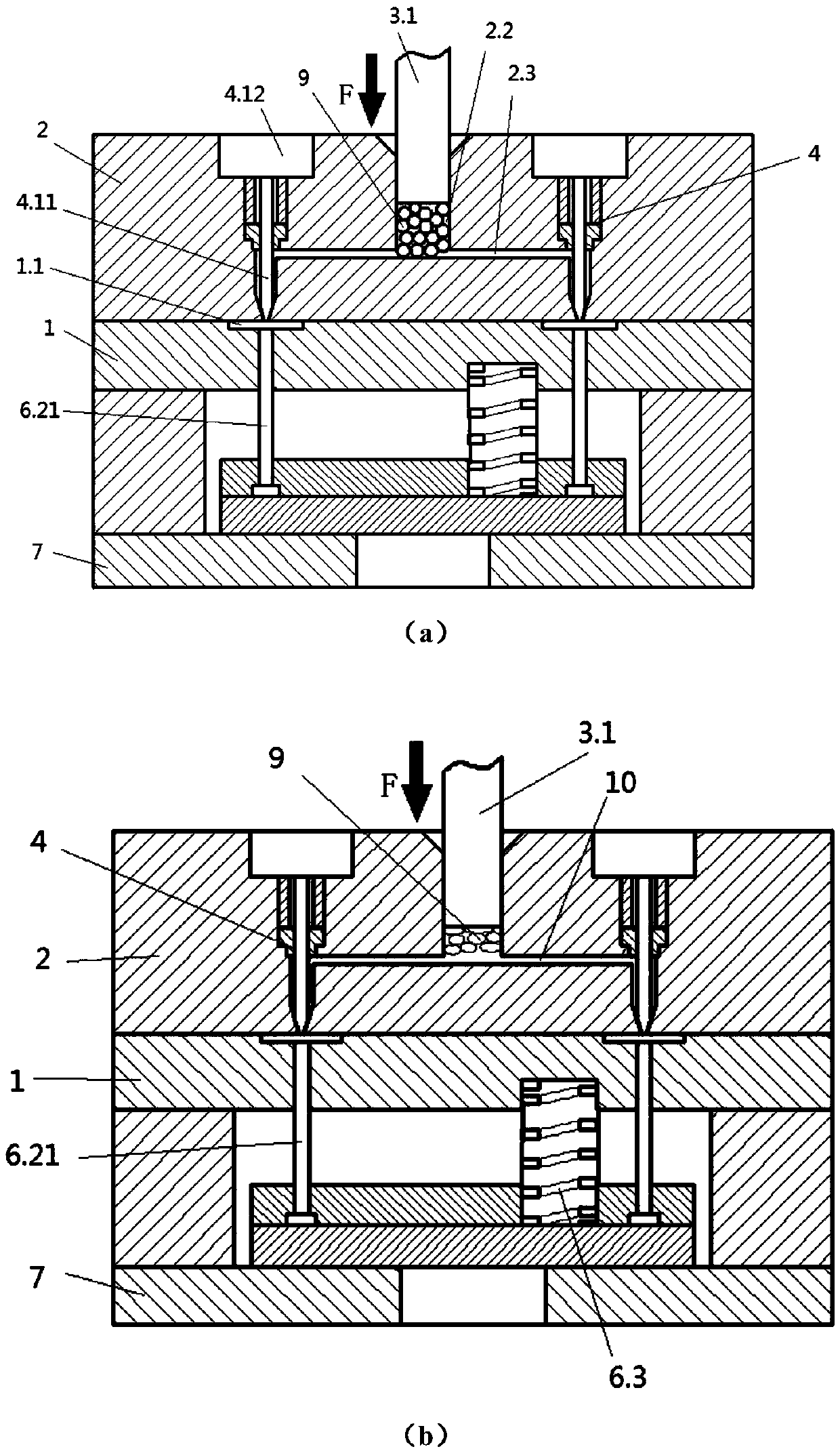

[0056] An ultrasonic plasticizing molding system, see figure 2 , including cavity template 1, plasticizing splitter template 2, plasticizing component 3, needle valve component 4, adjustable connector 5, pusher component 6 and fixed template 7, details are as follows:

[0057] The plasticizing splitter template 2, the cavity template 1 and the fixed template 7 are arranged from top to bottom.

[0058] The cavity template 1 is provided with two cavity 1.1 matching the shape of the workpiece 8 and a push channel 1.2 corresponding to the cavity 1.1 and communicating with the cavity 1.1, here: the cavity 1.1 Horizontal setting; there are two push rod channels, and the push rod channels are set along the vertical direction).

[0059] The plasticizing splitter template 2 includes a body 2.1, a plasticizing cavity 2.2 and two splitting channels 2.3, the plasticizing cavity 2.2 and the splitting channels 2.3 are both arranged in the body 2.1, and the splitting channels 2.3 Used to ...

Embodiment 2

[0075] The only difference between embodiment 2 and embodiment 1 is that it also includes a controller, the valve needle power source 4.12, the ultrasonic horn 3.1, the plasticizing power source, the adjustable connecting piece 5 and the push plate pushing unit. Connect with PLC controller. That is, each component operates under the control of the controller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com