An on-board vehicle intelligent oil change cleaning maintenance system suitable for appointment service

A technology for on-board vehicles and maintenance systems, applied in the field of intelligent oil change and cleaning maintenance systems for on-board vehicles, which can solve the problems of long oil change time and long waiting time for owners, and achieve the effects of reducing the impact of weather, simple structure, and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

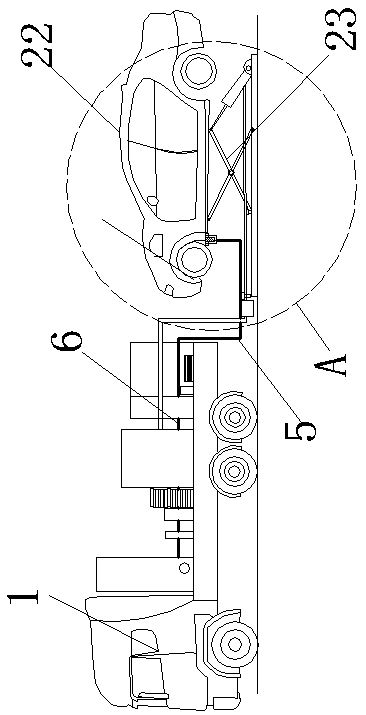

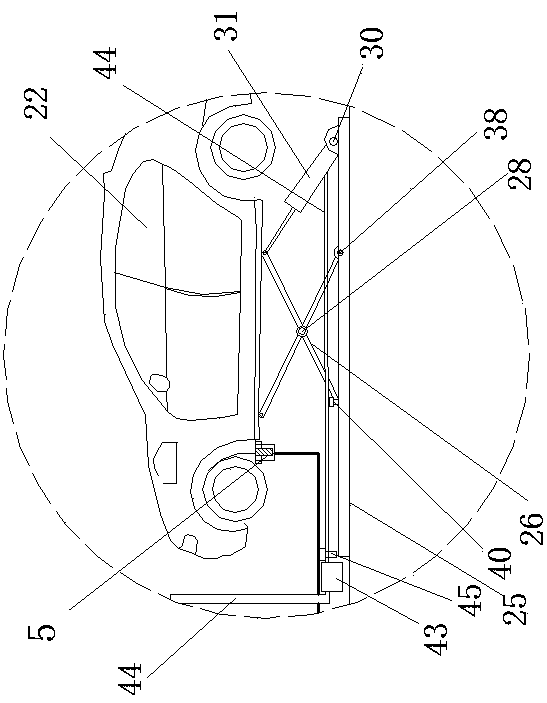

[0045] Example 1. Such as Figure 1-8 As shown, an on-board vehicle intelligent oil change, cleaning and maintenance system suitable for scheduled service is installed on the vehicle body 1, and the system includes an oil storage device, a lubricating oil mechanism, and a control device.

[0046] The oil storage device includes a recovery oil tank 2, a new oil tank 3, and a cleaning oil tank 11; the electromagnetic connecting valve 4 is provided with three oil inlets 41 and an oil outlet 42, and each oil inlet of the electromagnetic connecting valve 4 41. An electromagnetic valve is provided on the oil outlet 42, and the oil recovery tank 2, the new oil tank 3, and the cleaning oil tank 11 are respectively connected to an oil inlet 41 of the electromagnetic connecting valve 4 through the oil pipe 12, and the oil outlet 42 of the electromagnetic connecting valve 4 A hose 6 is connected to a refueling connector 5 , and a DC vacuum pump 7 is provided on the hose 6 between the el...

Embodiment 2

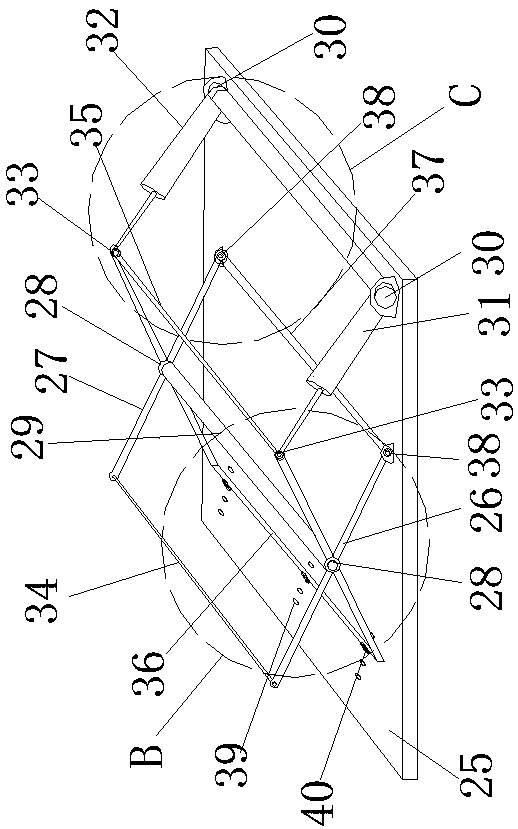

[0057] Example 2. Such as Figure 9-15 As shown, the difference between this embodiment and Embodiment 1 is that the oil storage device includes two recovery oil tanks 2, two new oil tanks 3, and two cleaning oil tanks 11; Six oil inlets 41 and two oil outlets 42 are arranged on the top, each oil inlet 41 and oil outlet 42 of the solenoid valve 4 are provided with electromagnetic valves, each recovery oil tank 2, new oil tank 3, and cleaning oil tank 11 They are respectively connected to an oil inlet 41 of the electromagnetic connecting valve 4 through the oil pipe 12; each oil outlet 42 is connected to a refueling joint 5 through a hose 6; A DC vacuum pump 7 is provided and an electromagnetic reversing valve 8 is provided on the DC vacuum pump 7 . The left sides of the front cross bar 26 and the rear cross bar 27 on the chassis 25 are respectively hinged with a front hydraulic cylinder 31 and a rear hydraulic oil cylinder 32 through a third connecting hinge 30. The central ...

Embodiment 3

[0058] Example 3. Such as Figure 16-20 As shown, the difference between this embodiment and Embodiment 1 is that the oil storage device includes a recovery oil tank 2, two new oil tanks 3, and a cleaning oil tank 11; Four oil inlets 41 and one oil outlet 42 are arranged on the top, each oil inlet 41 and oil outlet 42 of the electromagnetic Unicom valve 4 are provided with electromagnetic valves, and the recovery oil tank 2, the new oil tank 3, and the cleaning oil tank 11 are respectively Connect with an oil inlet 41 of the electromagnetic connecting valve 4 through the oil pipe 12; A DC vacuum pump 7 is provided on the hose 6 and an electromagnetic reversing valve 8 is provided on the DC vacuum pump 7 . The left end bottom of the front cross bar 26, the rear cross bar 27 and the chassis 25 are respectively hinged by a second connecting hinge 38 and the central axis of the hinge shaft of the second connecting hinge 38 is on the same line as the central axis of the fourth co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com