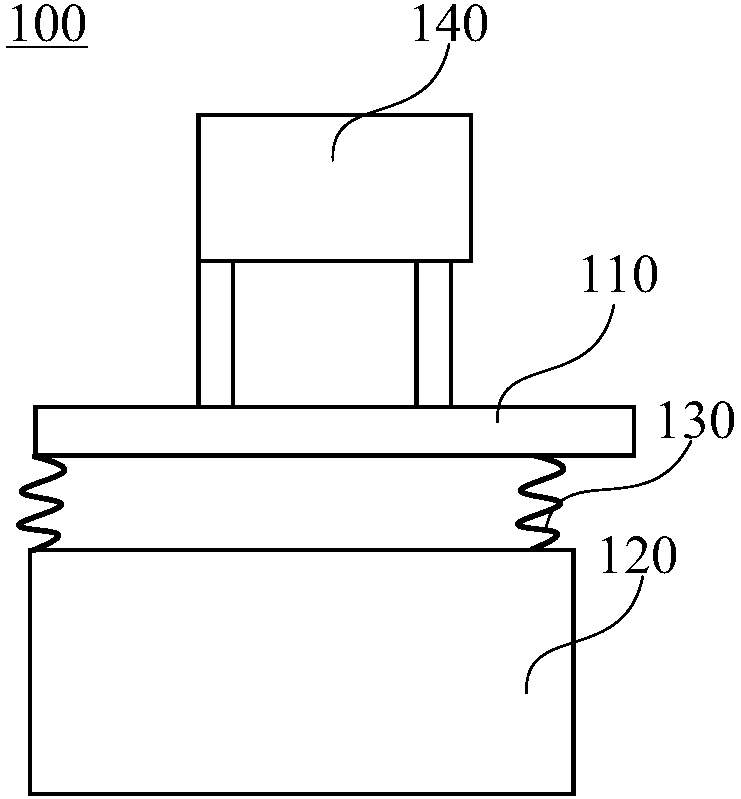

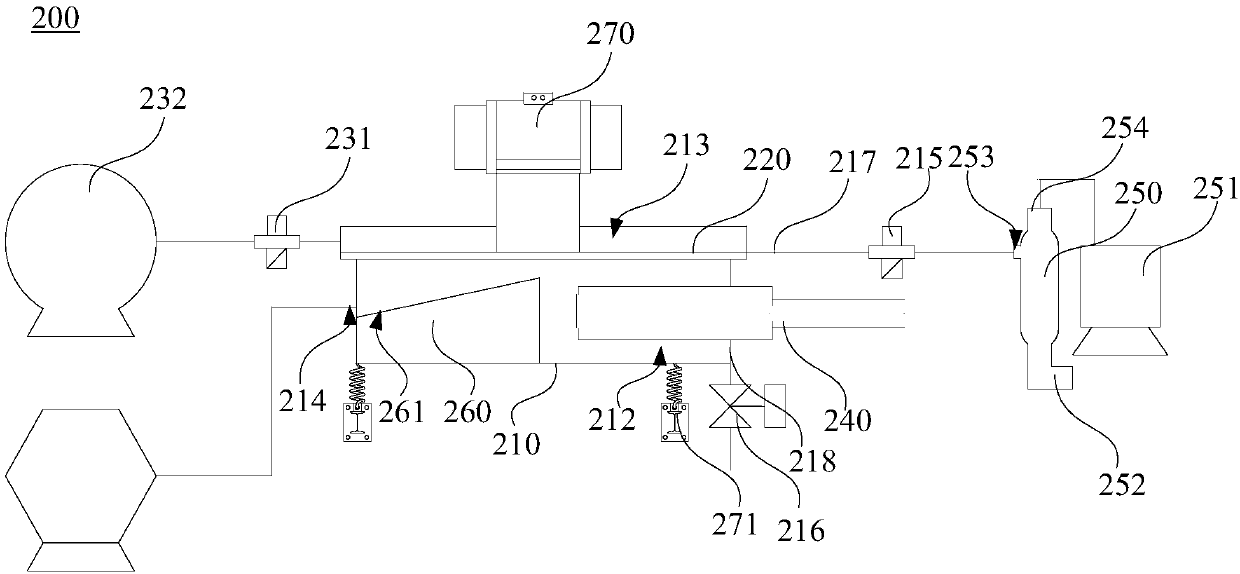

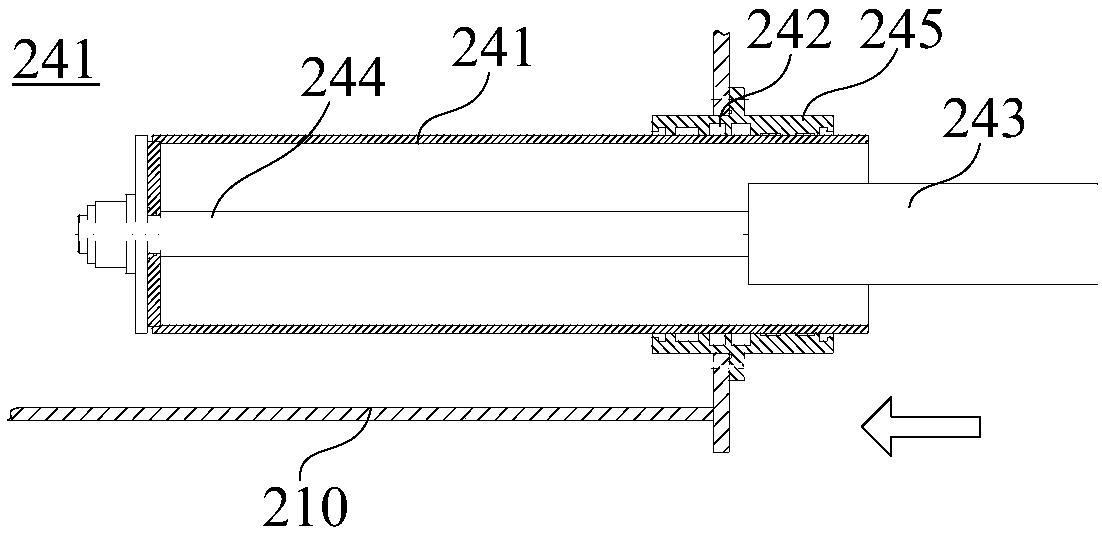

Mud-water separation device, mud-water separation system and use method of mud-water separation device

A technology of mud-water separation and gas-water separator, which is applied in the field of separation, can solve the problems of easy silting of the filter screen, achieve the effect of not easy to damage, efficient and convenient cleaning, and save time for cleaning mud

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] When the mud-water separation equipment filters the mud, the mud flows from one end of the filter unit to the other end, and what is filtered to the other end of the filter unit is water (lower density mud), while what stays at one end of the filter unit is sludge (density). higher mud). The inventors of the present invention have found after long-term research that when filtering, the mud often flows from a high place to a low place under the influence of gravity, thereby causing sludge to clog the filter unit. The inventors of the present invention also found that under the influence of gravity, not only can the sludge not escape from the filter unit, but it will further infiltrate into the filter unit to make the clogging more serious. And, when clearing the sludge clogged in the filter unit, if the sludge is allowed to filter the filter unit under the influence of gravity, the filter unit will be easily damaged; The sludge is not easy to clean, and the cleaning eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com