Preparation method of powdery coating having three-dimensional metal effect

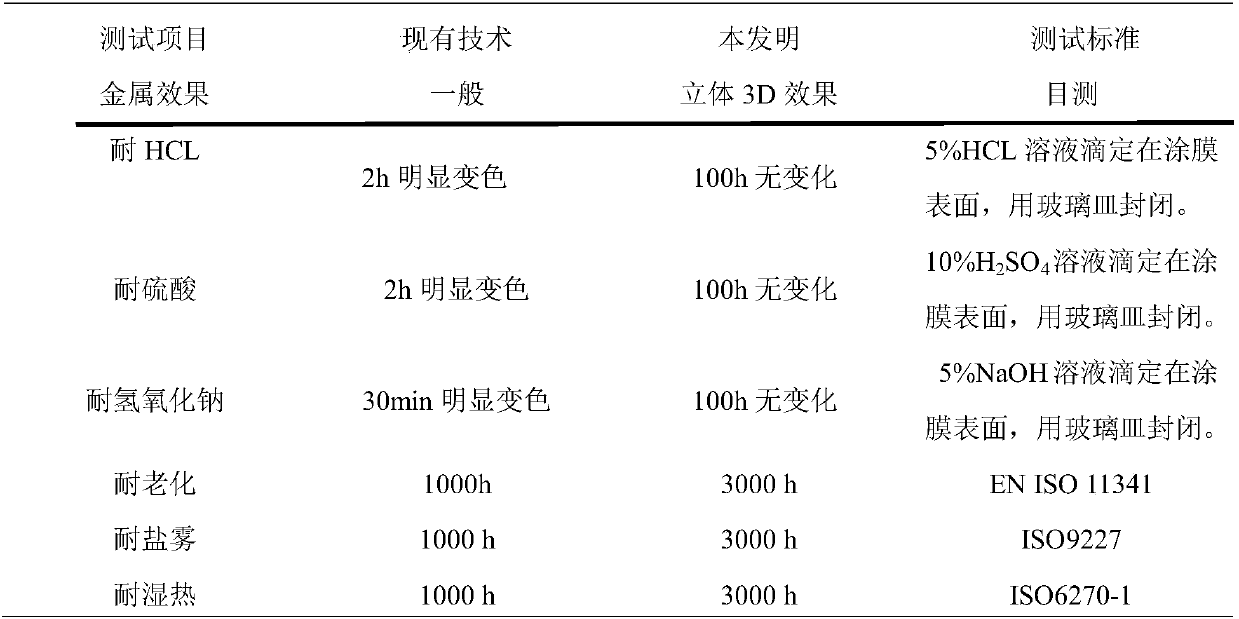

A metal effect, powder coating technology, applied in powder coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problems of metal effect powder coatings without three-dimensional effect, pigment arrangement and metal texture are not strong, flammable and explosive, etc. The effect of eliminating spraying defects, super strong metal three-dimensional texture, strong chemical resistance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment discloses a wrapped metal material, which is made of the following raw materials in parts by mass: 20-90 parts of acrylic resin, 0-20 parts of silicone resin, 0-20 parts of thermosetting fluorocarbon resin, hydroxyl or carboxyl polyester resin 0-70 parts, curing agent 10-15 parts, leveling agent 0.1-1.5 parts, degassing agent 0.5-1 part, metallic pigment 0.5-11 parts.

Embodiment 2

[0042] This embodiment discloses a wrapped metal material, which is made of the following raw materials in parts by mass: 25 parts of acrylic resin, 8 parts of thermosetting fluorocarbon resin, 25 parts of hydroxyl polyester resin, 12 parts of curing agent, 1 part of leveling agent, 0.5 part of degassing agent, 0.5 part of metallic pigment.

Embodiment 3

[0044] This embodiment discloses a wrapped metal material, which is made of the following raw materials in parts by mass: 40 parts of carboxyl polyester resin, 40 parts of epoxy resin, 10 parts of curing agent, 1 part of leveling agent, 1 part of degassing agent, 6 parts of metallic pigments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com