A kind of cold coating silver topcoat containing modified acrylic acid polymer resin A and preparation method thereof

An acrylic polymer and resin technology, applied in the coating and chemical fields, can solve the problems affecting the quality of the zinc dipping layer, the effect of the coating, and the complex construction process, and achieve good metal appearance effect, simple construction and application process, and color retention. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

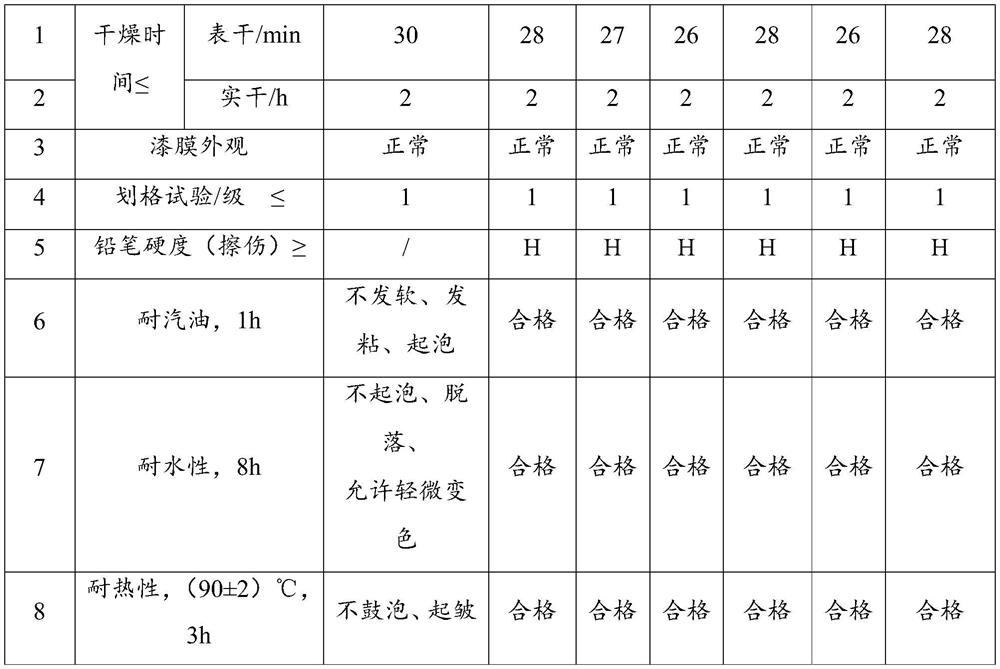

Embodiment 1

[0043] A kind of cold coating silver topcoat that contains modified acrylic polymer resin A, the concrete component and quality of the modified acrylic polymer resin A used in the preparation cold coating silver topcoat are as follows: methyl methacrylate 17kg, butyl acrylate 8kg of ester, 18kg of styrene, 8kg of functional monomer, 0.6kg of acrylic acid, 0.7kg of initiator, 35kg of hydrogenated toluene, 12.7kg of propylene glycol methyl ether acetate, the initiator in this formula includes dibenzoyl peroxide, benzene peroxide tert-butyl formate, 0.7kg of initiators include 0.42kg of dibenzoyl peroxide, 0.28kg of tert-butyl peroxybenzoate, functional monomers are cyclohexyl acrylate, hydrogenated toluene and propylene glycol methyl ether acetate Both are solvents.

[0044] The preparation method of the modified acrylic acid polymer resin A used in the cold coating silver topcoat is as follows:

[0045] S1: Add the formula amount of styrene into the batching tank, slowly add t...

Embodiment 2

[0060] A kind of cold coating silver topcoat that contains modified acrylic acid polymer resin A, the concrete component and quality of the modified acrylic polymer resin A used in the preparation cold coating silver topcoat are as follows: methyl methacrylate 21kg, butyl acrylate 10kg of ester, 18kg of styrene, 8kg of functional monomer, 0.7kg of acrylic acid, 0.8kg of initiator, 34kg of hydrogenated toluene, 7.5kg of propylene glycol methyl ether acetate, the initiator in this formula includes dibenzoyl peroxide, benzene peroxide tert-butyl formate, 0.8kg of initiators include 0.48kg of dibenzoyl peroxide, 0.32kg of tert-butyl peroxybenzoate, functional monomers are cyclohexyl acrylate, hydrogenated toluene and propylene glycol methyl ether acetate Both are solvents.

[0061] The preparation method of the modified acrylic acid polymer resin A used in the cold coating silver finish paint is as follows:

[0062] S1: add in the styrene of formula quantity in batching tank, slo...

Embodiment 3

[0077] A kind of cold coating silver topcoat that contains modified acrylic acid polymer resin A, the concrete component and the quality of the modified acrylic polymer resin A used in the preparation cold coating silver topcoat are as follows: methyl methacrylate 19kg, butyl acrylate 9kg of ester, 20kg of styrene, 9kg of functional monomer, 0.8kg of acrylic acid, 1kg of initiator, 30kg of hydrogenated toluene, 11.2kg of propylene glycol methyl ether acetate, the initiator in this formula includes dibenzoyl peroxide and benzoic acid peroxide tert-butyl ester, 1kg of initiator includes 0.6kg of dibenzoyl peroxide, 0.4kg of tert-butyl peroxybenzoate, functional monomer is cyclohexyl acrylate, hydrogenated toluene and propylene glycol methyl ether acetate are solvent.

[0078] The preparation method of the modified acrylic acid polymer resin A used in the cold coating silver finish paint is as follows:

[0079] S1: Add the formula amount of styrene into the batching tank, slowly a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com