Novel environment-friendly waterproof flame-retardant awning fabric and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

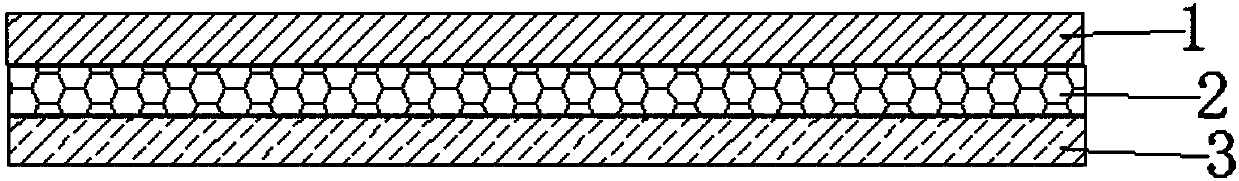

Image

Examples

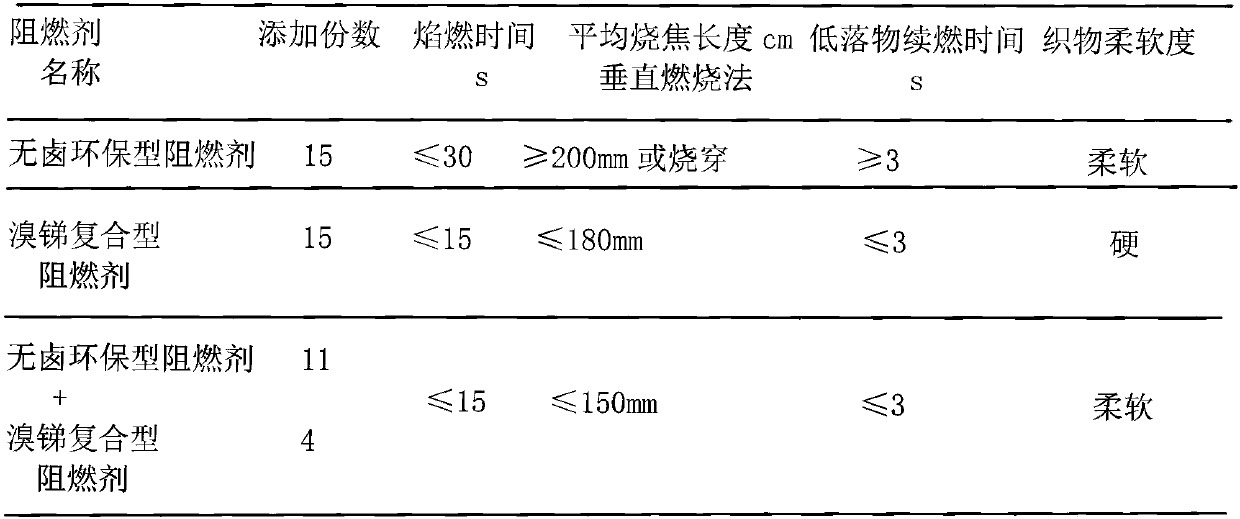

Embodiment 1

[0040] Step 1, base cloth layer treatment

[0041] Prepare 175T brocade silk as the base cloth layer, and subject the base cloth layer to hot-rolling treatment, the hot-rolling temperature is 120°C, and the calender roll pressure is 60T;

[0042] Step 2. Scratch the adhesive bottom layer

[0043] Step 2-1. Prepare the adhesive base layer, the specific components are as follows:

[0044] Polyether polyurethane 6065A, 90 parts;

[0045] Bottom curing agent L1470, 5 parts;

[0046] Bottom solvent toluene, 18 parts;

[0047] Bottom flame retardant CAS1309-64, 1 part;

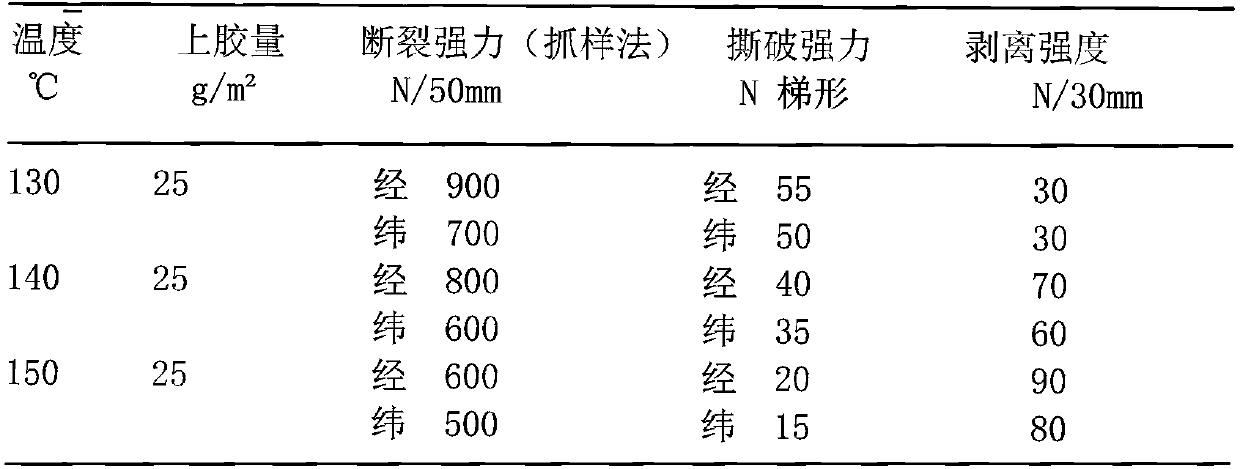

[0048] Step 2-2. Scrape-coat the adhesive bottom layer on the base fabric layer with two-coating and two-drying equipment. The process parameters are as follows: the temperature in the first zone is 90°C, the temperature in the second zone is 130°C; the vehicle speed is 15m / min, the amount of squeegee coating of the adhesive base layer is 25 g / cm 2 ;

[0049] Step 3, scrape the adhesive surface

[0050] Ste...

Embodiment 2

[0065] Step 1, base cloth layer treatment

[0066] Prepare 175T brocade silk as the base cloth layer, and subject the base cloth layer to hot rolling treatment, the hot rolling temperature is 140°C, and the calender roll pressure is 70T;

[0067] Step 2. Scratch the adhesive bottom layer

[0068] Step 2-1. Prepare the adhesive base layer, the specific components are as follows:

[0069] Polyether polyurethane 6386A, 100 parts;

[0070] Underlayer curing agent UN-7038, 7 parts;

[0071] Bottom solvent methyl ethyl ketone, 18 parts;

[0072] Bottom flame retardant CAS1309-64, 2 parts;

[0073] Step 2-2. Scrape-coat the adhesive bottom layer on the base fabric layer with two-coating and two-drying equipment. The process parameters are as follows: the temperature in the first zone is 100°C, the temperature in the second zone is 140°C; the vehicle speed is 18m / min, the coating amount of adhesive primer is 28 g / cm 2 ;

[0074] Step 3, scrape the adhesive surface

[0075] St...

Embodiment 3

[0083] Step 1, base cloth layer treatment

[0084] Prepare K59225 brocade silk as the base fabric layer, and subject the base fabric layer to hot-rolling treatment, the hot-rolling temperature is 160°C, and the calender roll pressure is 80T;

[0085] Step 2. Scratch the adhesive bottom layer

[0086] Step 2-1. Prepare the adhesive base layer, the specific components are as follows:

[0087] Polyether polyurethane 6065A, 90-110 parts;

[0088] Underlayer curing agent UN-7038, 8 parts;

[0089] Bottom solvent toluene, 20 parts;

[0090] Bottom flame retardant CAS1309-64, 2 parts;

[0091] Step 2-2. Scrape-coat the adhesive bottom layer on the base fabric layer using two-coating and two-drying equipment. The process parameters are as follows: the temperature in the first zone is 120°C, the temperature in the second zone is 150°C; the vehicle speed is 20m / min, the amount of squeegee coating of the adhesive base layer is 30 g / cm 2 ;

[0092] Step 3, scrape the adhesive surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com