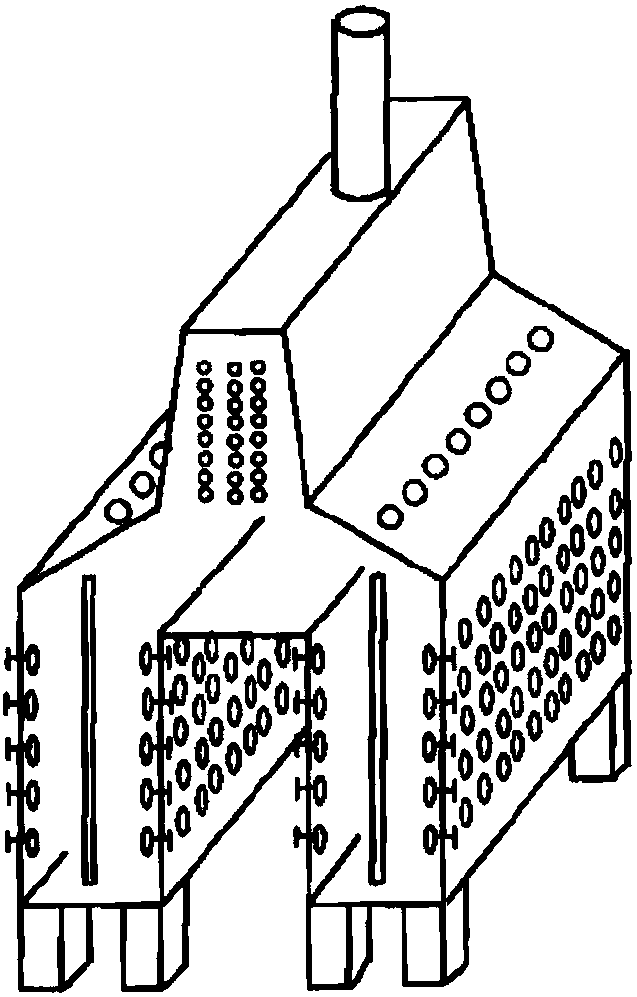

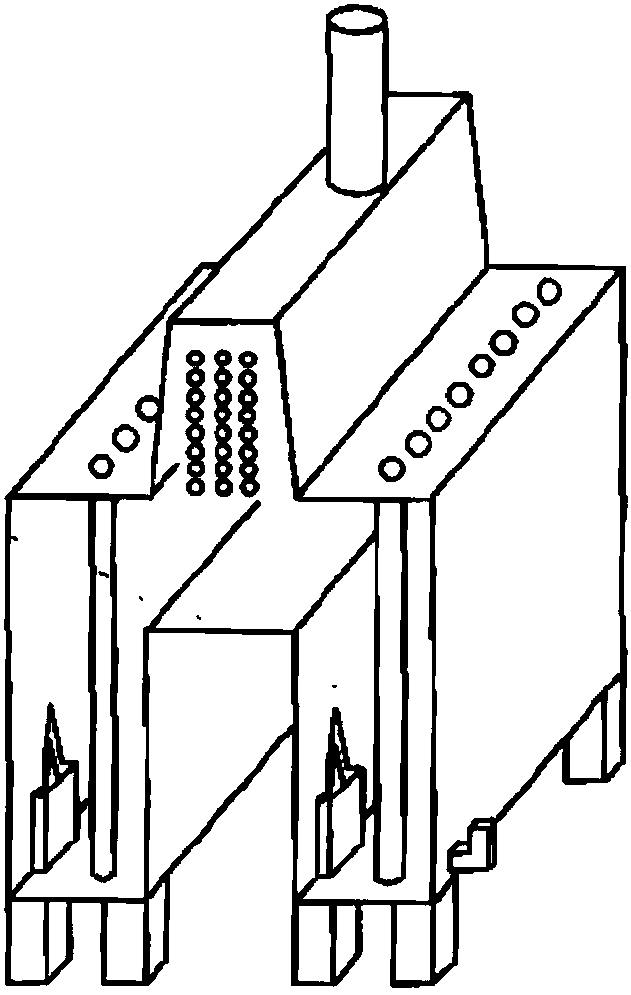

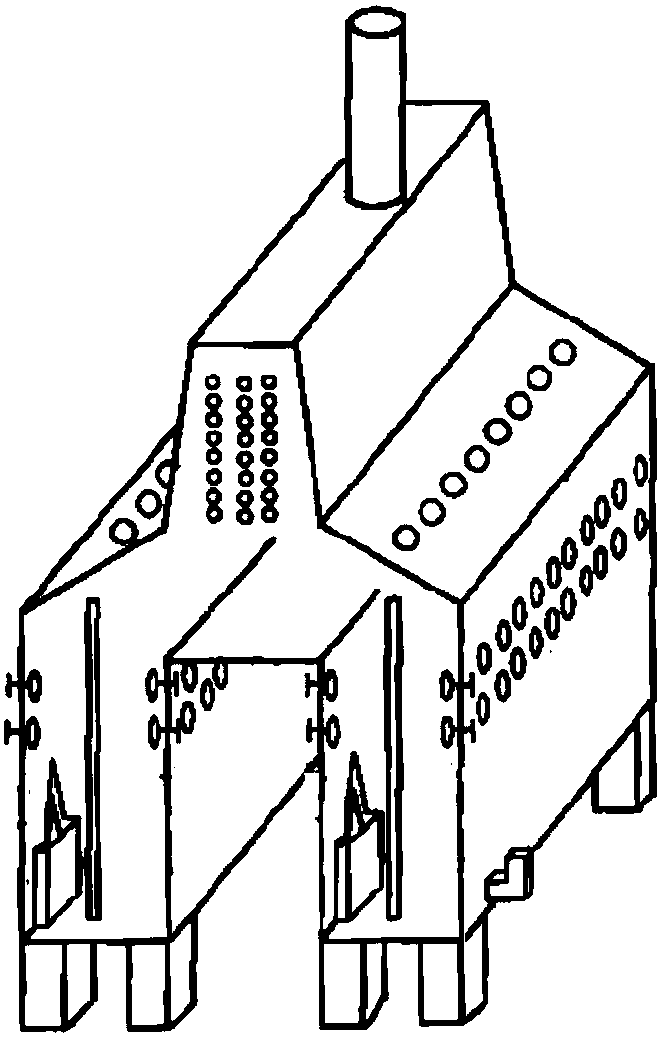

Ethylene cracking furnace

A technology of ethylene cracking furnace and hearth, which is applied in the direction of cracking, hydrocarbon cracking to hydrocarbon, non-catalytic thermal cracking, etc. It can solve the problems that the outer wall of the furnace is easy to overheat, it is difficult to meet the emission standard, and the flame is turned over, so as to avoid the interference of the upper and lower flames. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Preferred embodiments of the present invention will be described in more detail below with reference to the accompanying drawings. Although preferred embodiments of the invention are shown in the drawings, it should be understood that the invention may be embodied in various forms and should not be limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art.

[0040] In the present invention, if there is no clear contrary explanation, the "inlet pipe" in the radiant furnace tube can refer to the radiant furnace tube where the hydrocarbon material enters the radiant section from the top, and the "outlet pipe" can refer to the cracked hydrocarbon material enters from the top. Radiant furnace tubes of condensing boilers; "upper, lower, left, right, front, rear, vertical" can refer Figure 4, where "up and down" can ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com