A drying method for an integrated washing and drying machine and an integrated washing and drying machine

An all-in-one machine, washing and drying technology, applied in the field of clothes drying, can solve the problems of poor drying uniformity, poor drying degree, and poor drying uniformity of drying objects, and achieve the effect of uniform heating and fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

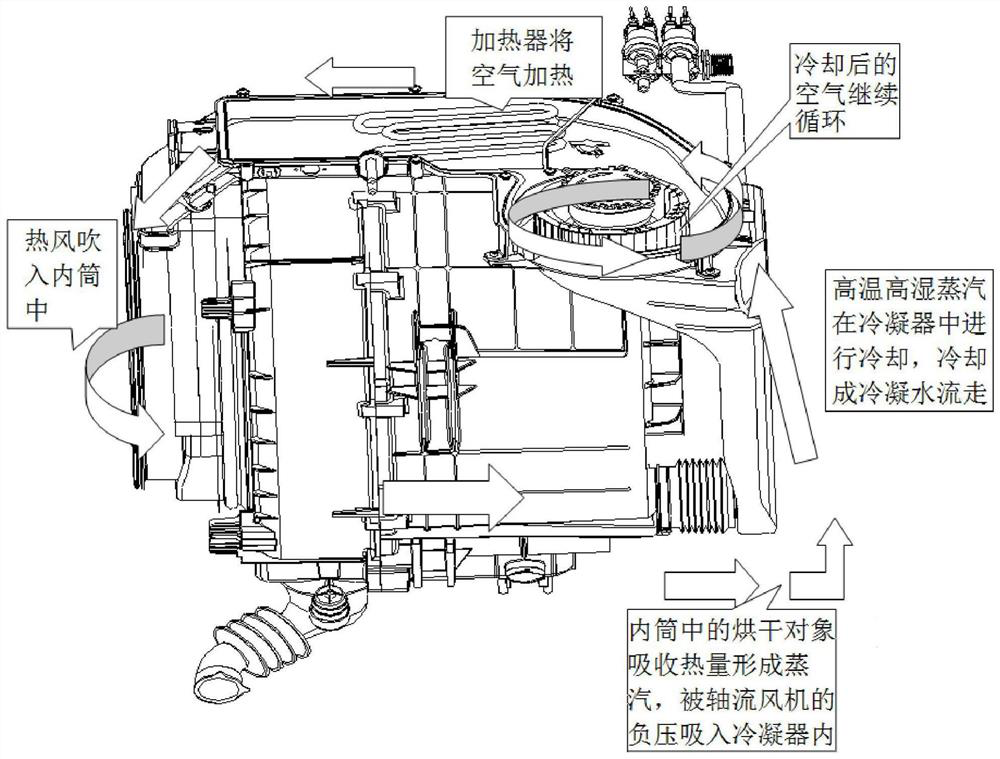

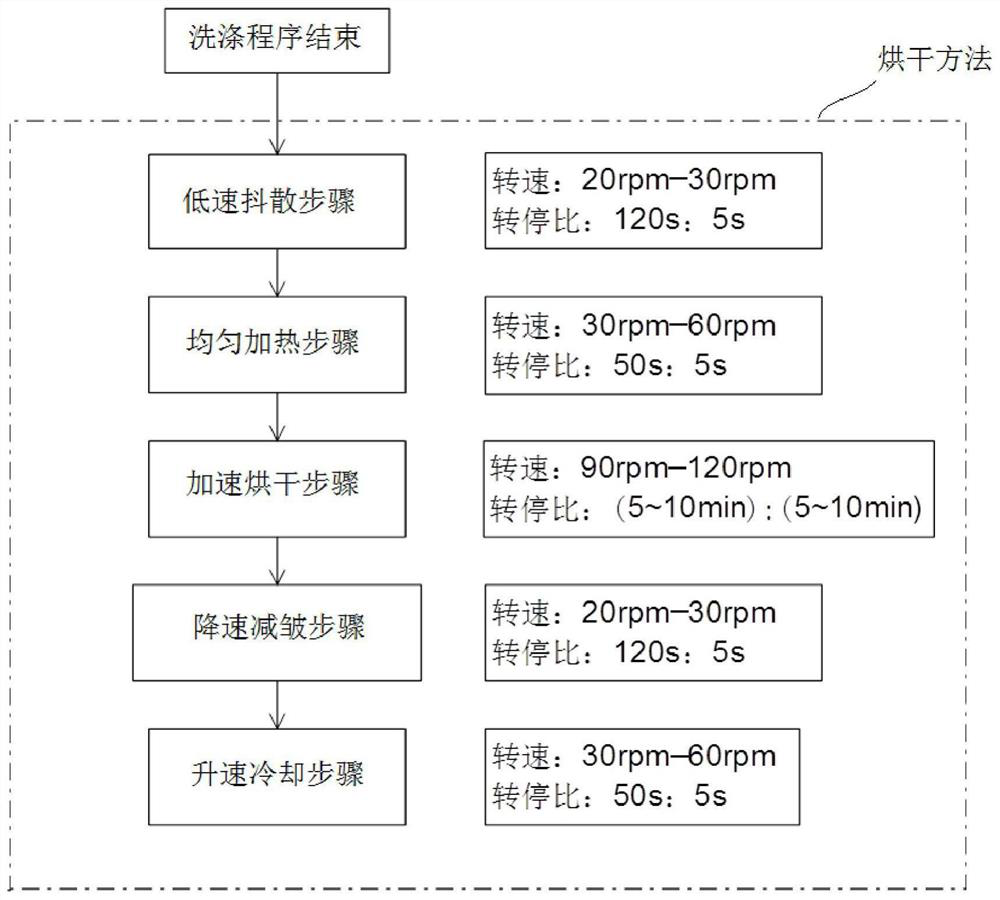

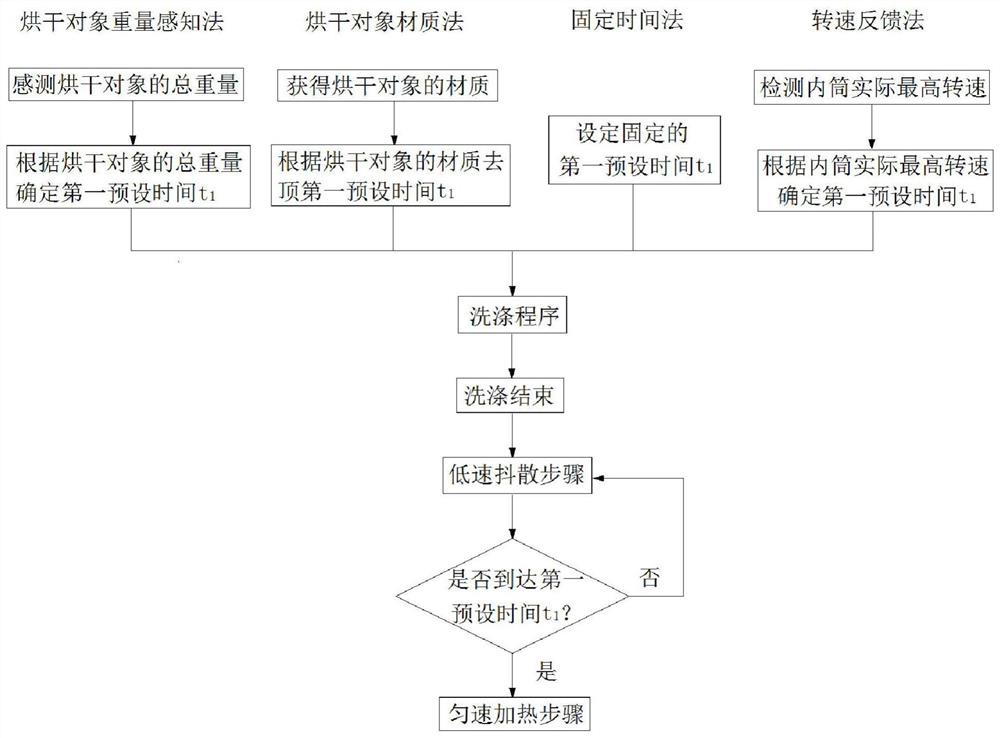

[0038] Refer figure 1 The drying principle of the current washing machine is to heat the air by a heater (e.g., a set of heating wire), the heated air (i.e., hot air) is blown into the inner cylinder by the fan in the inner cylinder to form a hot air, drying within the inner tube The object is thermally evaporated into high-temperature and high humid steam, and the high-temperature and high-humid steam is formed by the negative pressure inserted by the axial flow fan, and the high-temperature and high humidity steam is condensed into condensed water, condensed water. Under the outer wall of the unit, the air after cooling continues to circulate. During the current drying process, the inner cylinder is set to fix the speed, and the fixed rotation is rotated solely to rotate quickly to dry the drying object. However, with the increase in the capacity of the drying target, in particular, the drying of the drying target of different positions in the inner cylinder has a uniformity of ...

Embodiment 2

[0070] In the present embodiment, a dried drying machine is provided which is a drying method for a dry drying machine using the above-described embodiment. Therefore, the washing machine can make the hot air to better contact with the inner cylinder intermediate and rear portion, improve the drying uniformity of the drying target, and improve the drying performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com