Vertical connection node component for modularized buildings and construction method of vertical connection node component

A technology for connecting nodes and connectors, applied in the direction of architecture and building structure, etc., can solve the problems of destroying the overall decoration, affecting the application range of type nodes, and reducing the height of the building.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further illustrated below by specific examples.

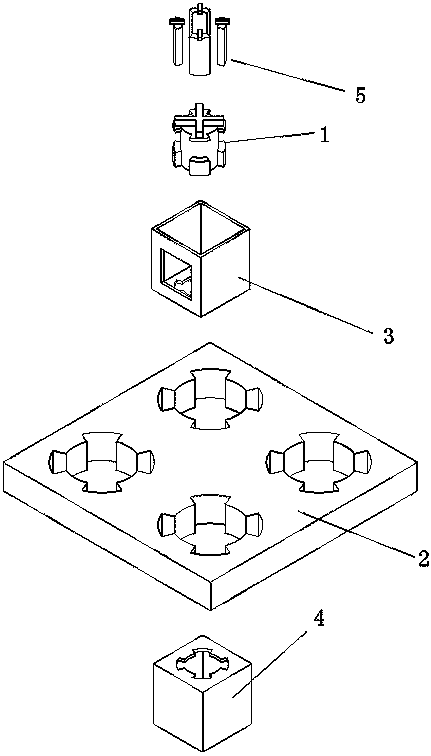

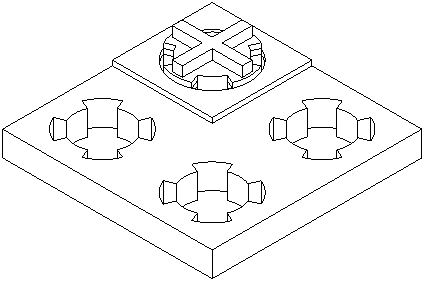

[0020] Such as figure 1 , figure 2 As shown, a vertical connection node assembly of a modular building includes a rotating member 1, a multi-column connecting plate 2, an upper column connecting member 3, a lower column connecting member 4 and an insert body 5; wherein the rotating member includes a round steel column 1. The bottom bosses and top bosses are respectively arranged at the bottom and top of the round steel column, and a cross rotation rod is also arranged on the top surface of the top boss; the multi-column connecting plate 2 is used to connect the upper and lower floors and surrounding columns, which includes The connection plate body and the multiple sets of connection holes on the connection plate body are provided, and the cross-sectional shape of the connection hole is the same as the projection shape of the rotating part; Opening, the opening on the bottom surface is an inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com