Mechanical section hoop positioner and application method thereof

A technology of mechanical joints and locators, which is applied in the directions of earth-moving drilling, drilling pipes, casings, etc., can solve the problems that the induction block cannot be compressed back into the casing 1, and the accident of sticking, and achieves a small amount of wear, Reliable work, increase the effect of induction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

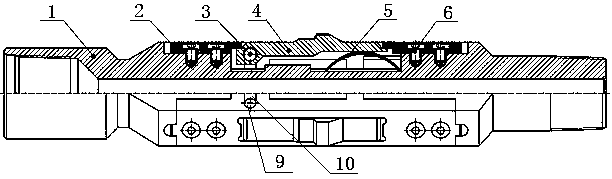

[0023] This embodiment provides a figure 1 The shown mechanical segment hoop positioner includes a housing 1, and a plurality of pressure plates 2 are fixed on the outer wall of the housing 1 at uniform intervals along the circumference, and each pressure plate 2 is provided with a long strip hole, and the long strip hole is embedded with a sensor block 4, an arc-shaped spring piece 5 is placed between the induction block 4 and the housing 1, the arc top of the arc-shaped spring sheet 5 is in contact with the induction block 4, and the contact point of the arc top is close to the bottom of the induction block 4, and the induction block 4 A hinge control mechanism is connected with the block 4 and the pressing plate 2 .

[0024] The design of the mechanical section hoop positioner is as follows: a plurality of pressure plates 2 are evenly distributed in the circumferential direction and attached to the shell 1. After the lamination, the outer diameter remains unchanged. The in...

Embodiment 2

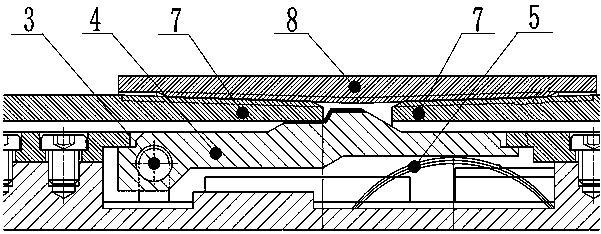

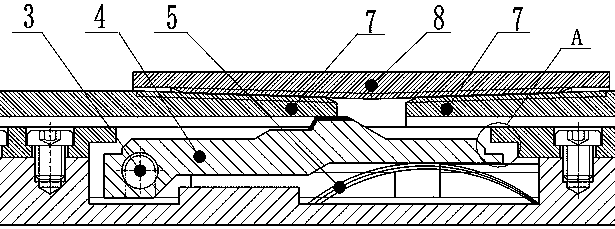

[0028] On the basis of Example 1, such as figure 1 , figure 2 with image 3 As shown, the hinge control mechanism is composed of a small hole 9, a pin shaft 3 and a groove 10, the small hole 9 is set on the induction block 4 along the short side of the elongated hole and runs through the induction block 4, the groove 10 There are two opposite ones on each pressing plate 2, and the two grooves 10 respectively correspond to the two ports of the small hole 9, the pin shaft 3 passes through the small hole 9, and the two ends of the pin shaft 3 overlap the groove 10 inside and can move along the radial direction of the housing 1.

[0029] The upper end of the induction block 4 is horizontally processed with a small hole 9, and the pressure plate 2 is processed with a groove 10 corresponding to the small hole 9 of the induction block 4. The width of the groove 10 is slightly smaller than the diameter of the small hole 9 on the induction block 4. The induction block 4 and the pres...

Embodiment 3

[0032] On the basis of Embodiment 2, the pin shaft 3 is a stepped shaft with a small diameter at both ends and a large middle diameter, and the width of the groove 10 is smaller than the diameter of the small hole 9 . Bearing pin 3 is processed into two ends small middle big step shaft, and its middle shaft just passes through the aperture 9 on the induction block, and the small shaft at two ends just puts in the groove 10 on the pressure plate. Bearing pin 3 is processed with a shoulder, thick in the middle and thin at both ends, so that pin shaft 3 can not come off from the pressing plate like this.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com