Dryer provided with uniform air distributing system

A technology of air distribution system and dryer, which is applied in the direction of dryer, drying, progressive dryer, etc. It can solve the problems of uneven drying of local materials, reduction of finished product quantity, and influence on work efficiency, so as to avoid secondary Drying operation, increase the settlement distance, improve the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

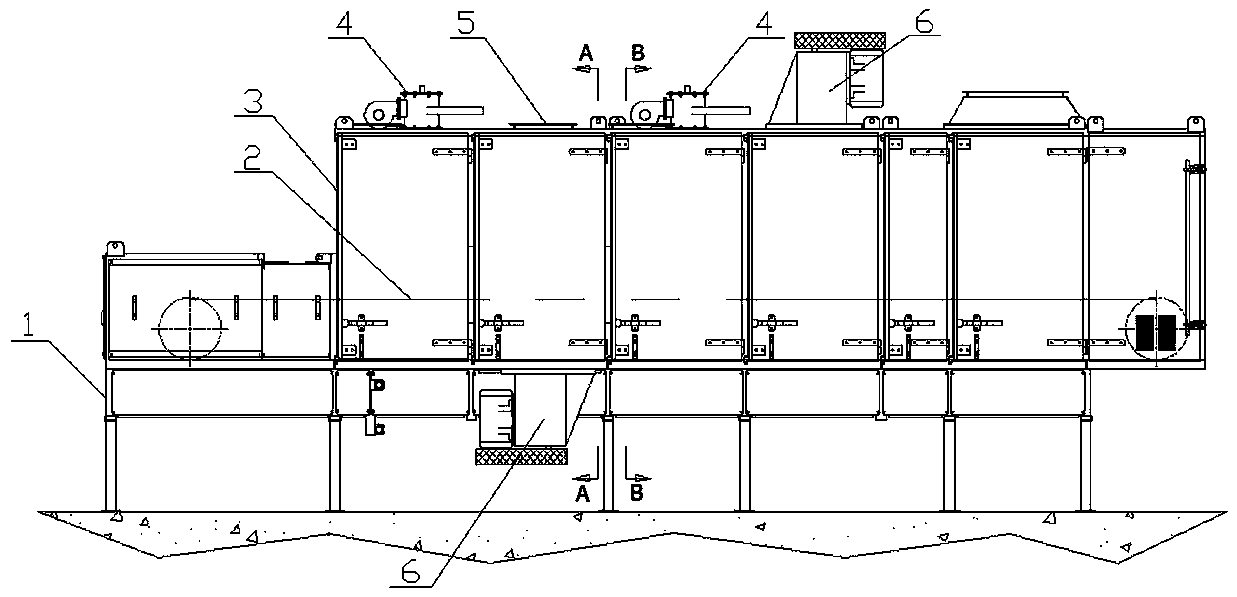

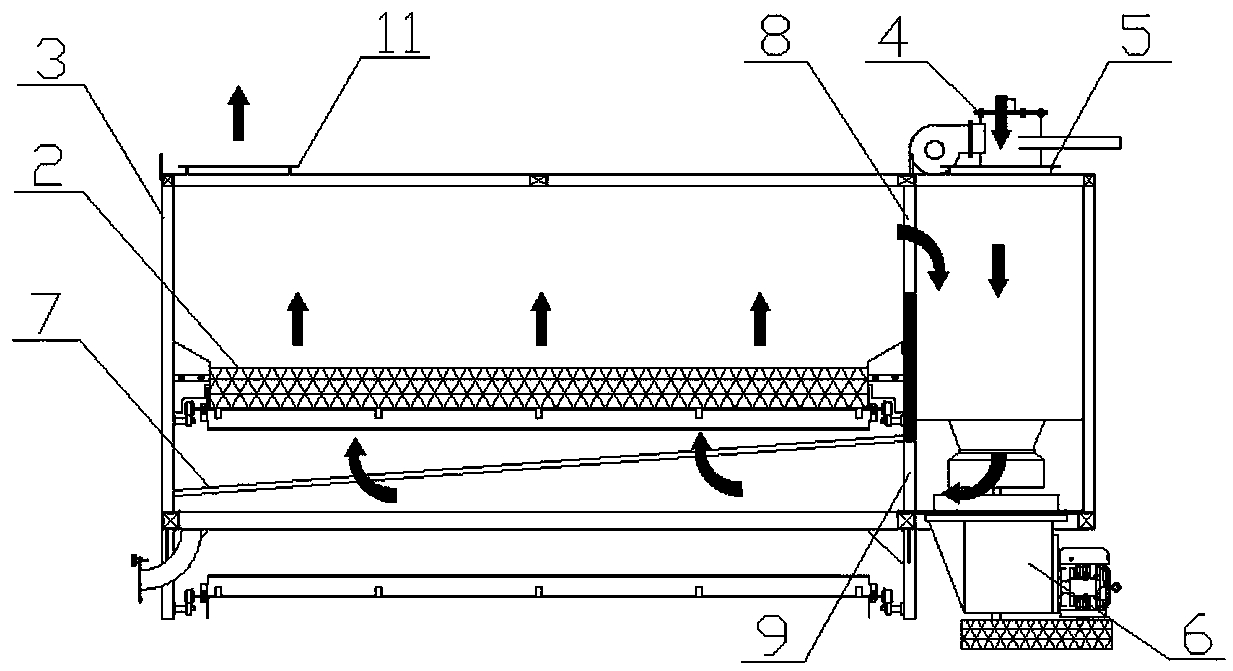

[0020] Such as figure 1 and figure 2 As shown, the dryer with a uniform air distribution system of the present invention includes a frame 1, on which a drying box 3 is arranged longitudinally and continuously, and on the frame 1 is a conveyor belt 2 that runs through the inner cavity of the drying box 3 . One side of the drying box 3 is connected with a hot air device, and there is an air outlet 9 and an air return port 8 between the hot air device and the drying box 3, and the air outlet 9 and the air return port 8 are respectively located on the upper and lower sides of the conveyor belt 2. Described hot blast device comprises hot blast box 10, and burner 4 and induced draft fan 6 are arranged on hot blast box 10, and the heating opening of burner 4 stretches in hot blast box 10, and the induced draft outlet of induced draft fan 6 is aimed at described air outlet 9 . There is an air distribution plate 7 inside the drying box 3 between the air outlet 9 and the conveyor be...

Embodiment 2

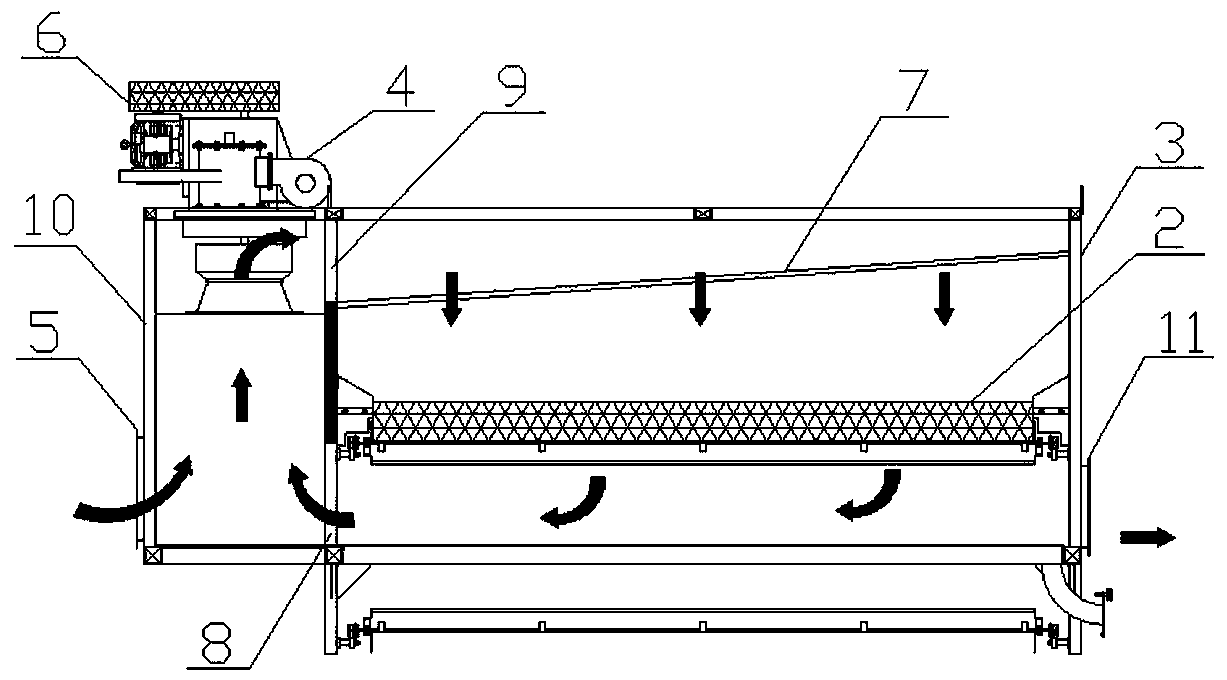

[0023] Such as figure 1 and image 3 As shown, the dryer with a uniform air distribution system of the present invention includes a frame 1, on which a drying box 3 is arranged longitudinally and continuously, and on the frame 1 is a conveyor belt 2 that runs through the inner cavity of the drying box 3 . One side of the drying box 3 is connected with a hot air device, and there is an air outlet 9 and an air return port 8 between the hot air device and the drying box 3, and the air outlet 9 and the air return port 8 are respectively located on the upper and lower sides of the conveyor belt 2. Described hot blast device comprises hot blast box 10, and burner 4 and induced draft fan 6 are arranged on hot blast box 10, and the heating opening of burner 4 stretches in hot blast box 10, and the induced draft outlet of induced draft fan 6 is aimed at described air outlet 9 . There is an air distribution plate 7 inside the drying box 3 between the air outlet 9 and the conveyor bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com