Plasma pressure sensor and plasma pressure sensing system

A pressure sensor, plasma technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problems of high arc energy and difficult control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

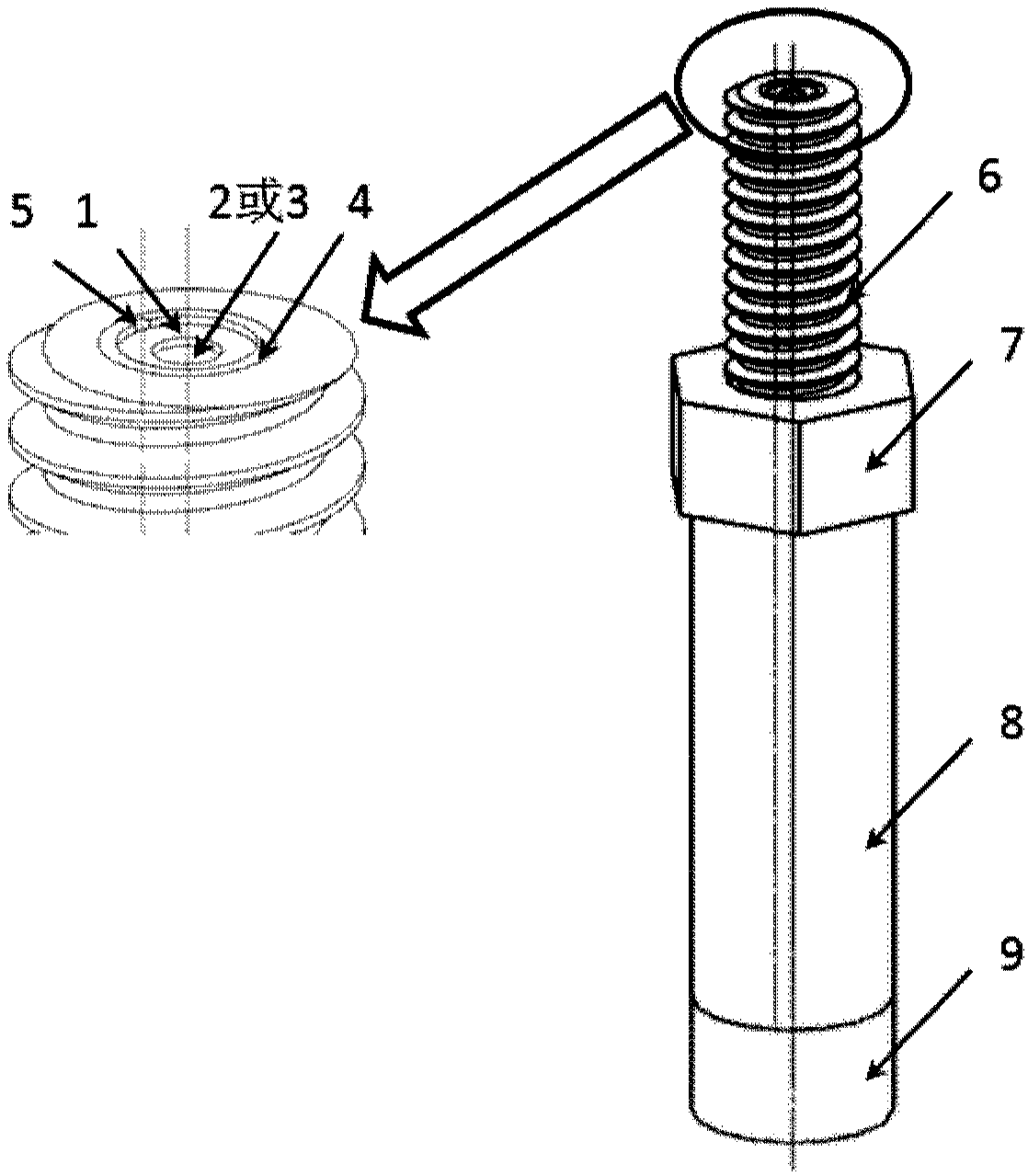

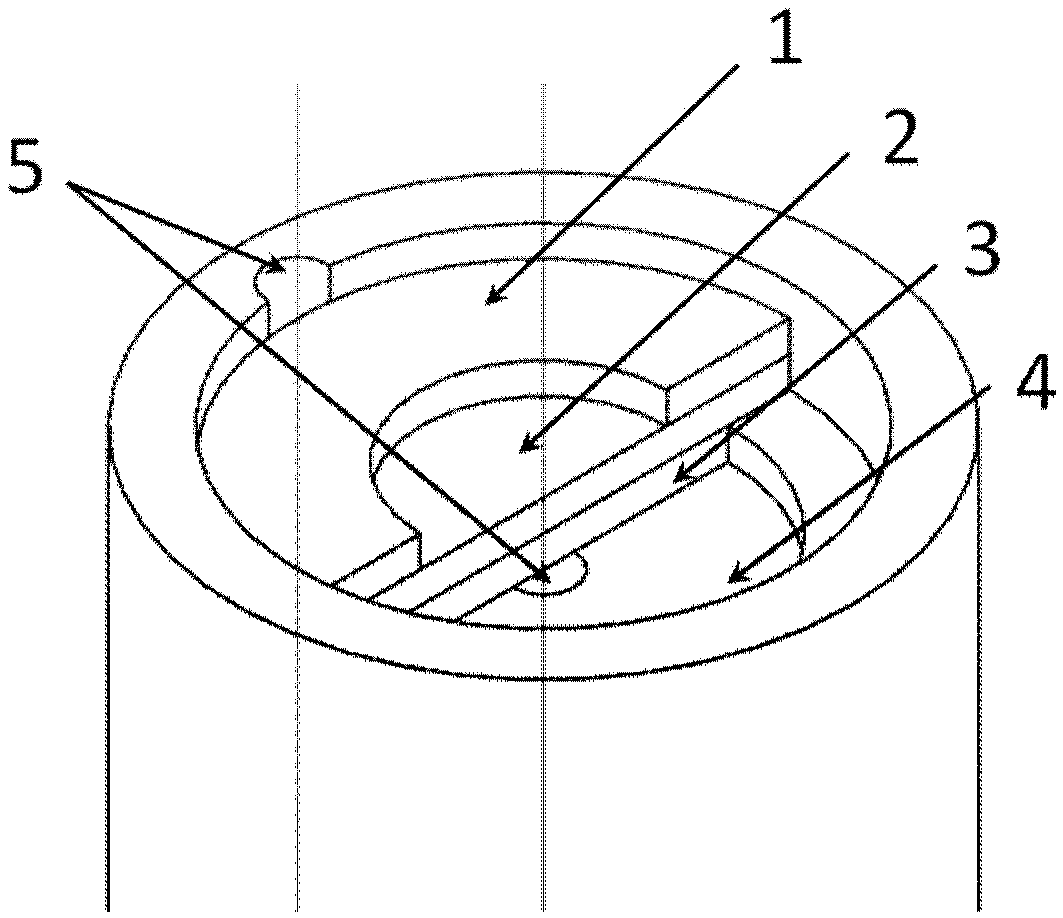

[0038] In view of this, we expect to be able to work stably in glow discharge, so in order to solve this problem and increase the measurable air pressure range, the present invention adopts a buried metal electrode discharge structure.

[0039] This plasma pressure sensor can not only conceptually improve the existing measurement methods and improve the measurement accuracy, but also provide more detailed flow field detail data for the verification and development of high-reliability three-dimensional flow numerical simulation methods, thus providing support for the development of turbomachinery. Clarification of internal flow mechanism, blade optimization design and development of stability expansion technology provide more effective research methods and lay the foundation for improving my country's aerodynamic equipment development capabilities.

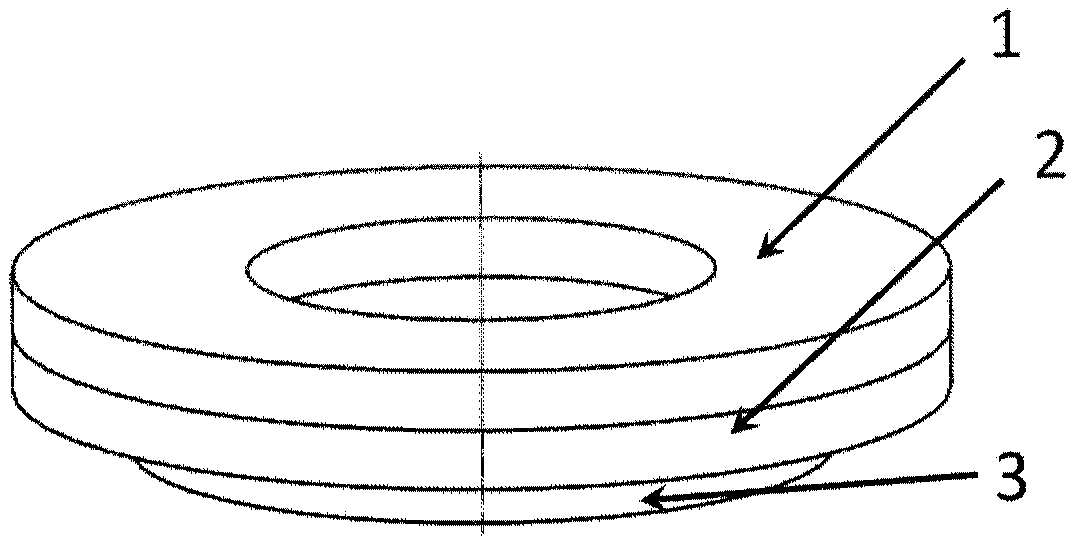

[0040] The present invention provides a plasma pressure sensor, which includes a discharge electrode, and the discharge electrode i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com