High-calorific-value easily-ablated artificial de-bonding layer material and preparation method thereof

A layer material, high calorific value technology, applied in the direction of offensive equipment, compressed gas generation, explosives, etc., can solve the problems of small contribution to the total impact of solid ramjet engines, waste of resources, and non-provision, so as to increase temperature and pressure, increase engine The effect of total flushing and high calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

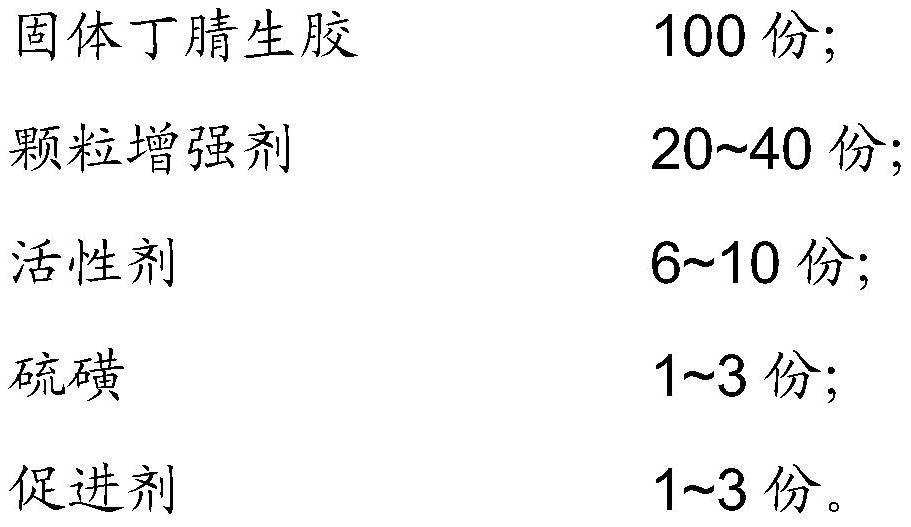

[0037] According to a second aspect of the present invention, there is provided a method for preparing an artificial debonding layer material with high calorific value and easy ablation, the method comprising the following steps:

[0038] Add particle reinforcing agent, active agent, sulfur and accelerator to solid nitrile butadiene raw rubber that has been masticated, and pressurize and vulcanize after sufficient mixing to prepare artificial debonding layer material.

[0039] Wherein, the selection and raw material ratio of solid nitrile raw rubber and particle reinforcing agent, active agent, sulfur and accelerator are consistent with those described in the first aspect.

[0040] In a preferred embodiment, during the preparation of the artificial debonding layer material, a calorific value enhancer is also added in the mixing stage, and the calorific value enhancer includes any one of aluminum powder, magnesium powder or boron powder One or more, preferably boron powder. Th...

Embodiment 1

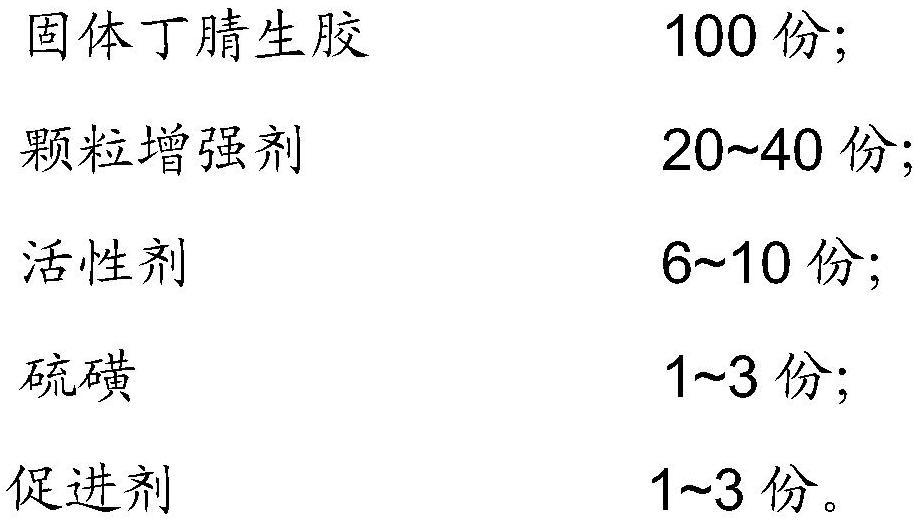

[0047] The artificial debonding layer material with high calorific value and easy ablation is made of the following raw materials in parts by weight:

[0048]

[0049] The preparation method is as follows: masticating solid nitrile rubber in an open mill; 2) adding carbon black and boron powder of the above weight, and fully mixing; 3) adding zinc oxide and stearic acid of the above weight, fully mixing; 4) Add the above weight of sulfur and accelerator M, and mix fully; 5) In the open mill, reverse the thin pass in the form of a triangular bag, and release the sheet for use; 6) The material is made into a test piece by mold pressurization, The process parameters are: vulcanization temperature 160°C, vulcanization pressure 15Mpa, vulcanization time 40 minutes.

Embodiment 2

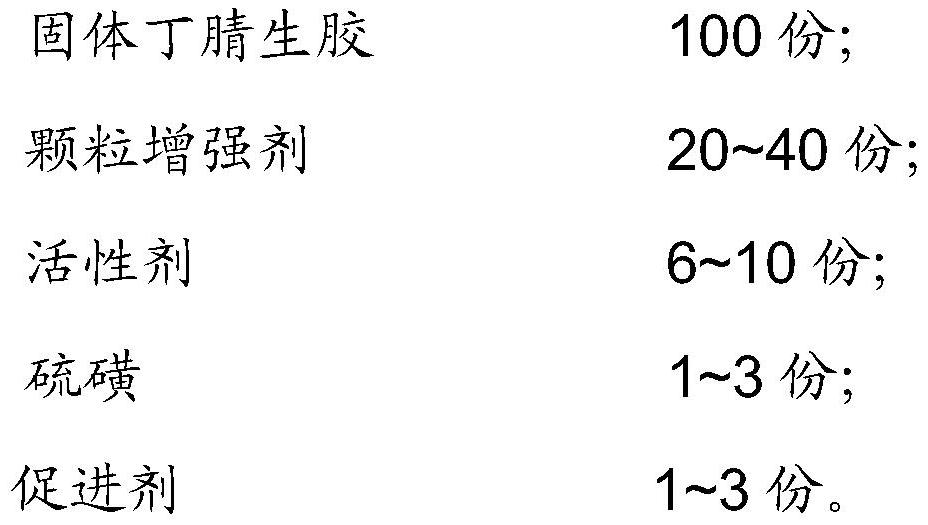

[0051] The artificial debonding layer material with high calorific value and easy ablation is made of the following raw materials in parts by weight:

[0052]

[0053] The preparation method is consistent with that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com