Particle pressure junction type diode anode target for pulse power device and preparation method of particle pressure junction type diode anode target

A technology of pulsed power and anode target, which is applied in the direction of ion implantation plating, coating, metal material coating process, etc., can solve the problems of low experimental efficiency and economic benefit, anode ablation, deformation, etc., and achieve enhanced thermo-mechanical Effects of damage performance, life improvement, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

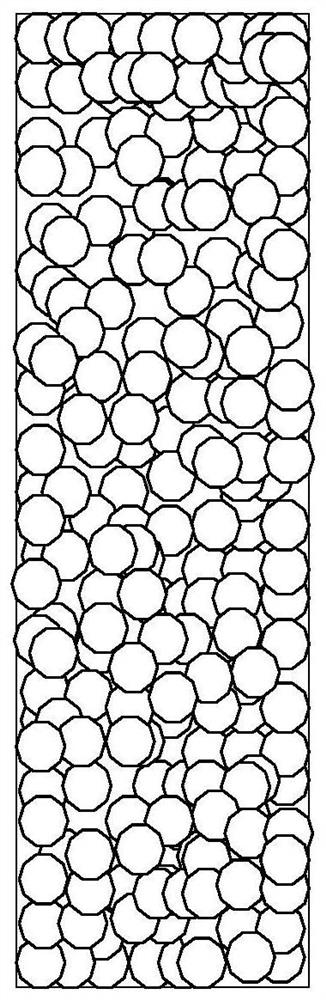

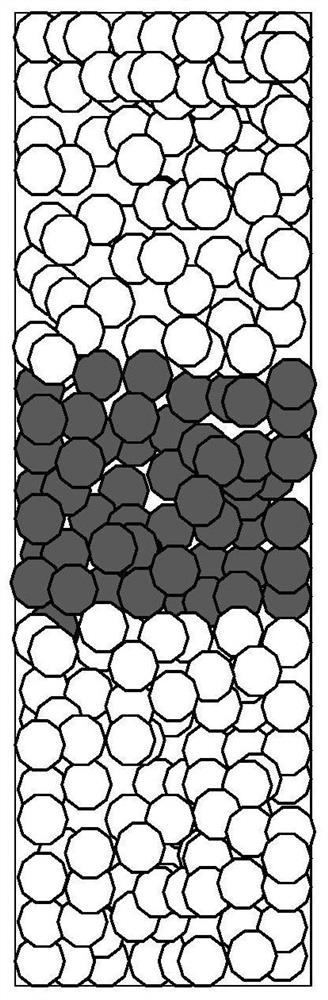

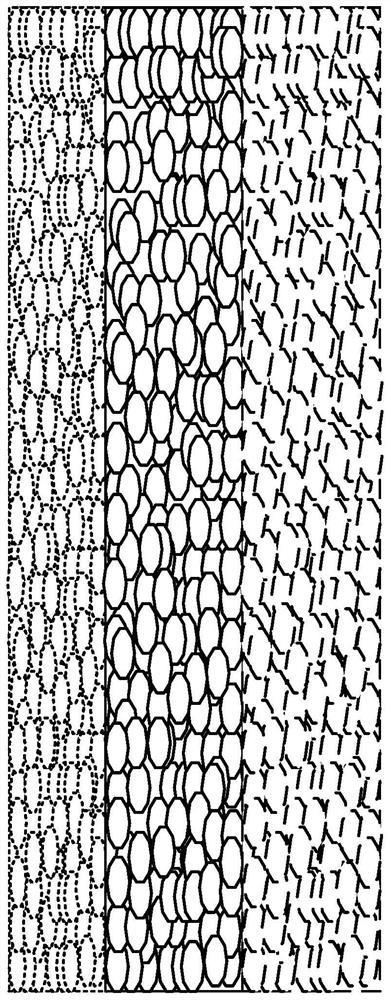

[0036] Most of the existing anode targets are single-use and need to be replaced after each experiment is completed. The invention provides a granular pressure-junction diode anode target used in a pulse power device and a preparation method. The anode target has a long service life and can replace the monolithic single-layer tantalum target used in existing high-current diodes. At the same time, the anode target is different from the existing ordinary low-energy industrial targets, and is mainly used in the field of high-power pulse technology. The anode target can withstand hundreds of kA, hundreds of kV to several MV high-en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com