Modularized reusable multiunit circle-to-square compression ratio plug nozzle testing device

A plug-type nozzle and test device technology, which is applied to jet propulsion devices, rocket engine devices, machines/engines, etc., can solve the problems of difficult work, high cost, limited experimental tasks, etc., and achieves convenient replacement, convenient disassembly, The effect of low cost of continued use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

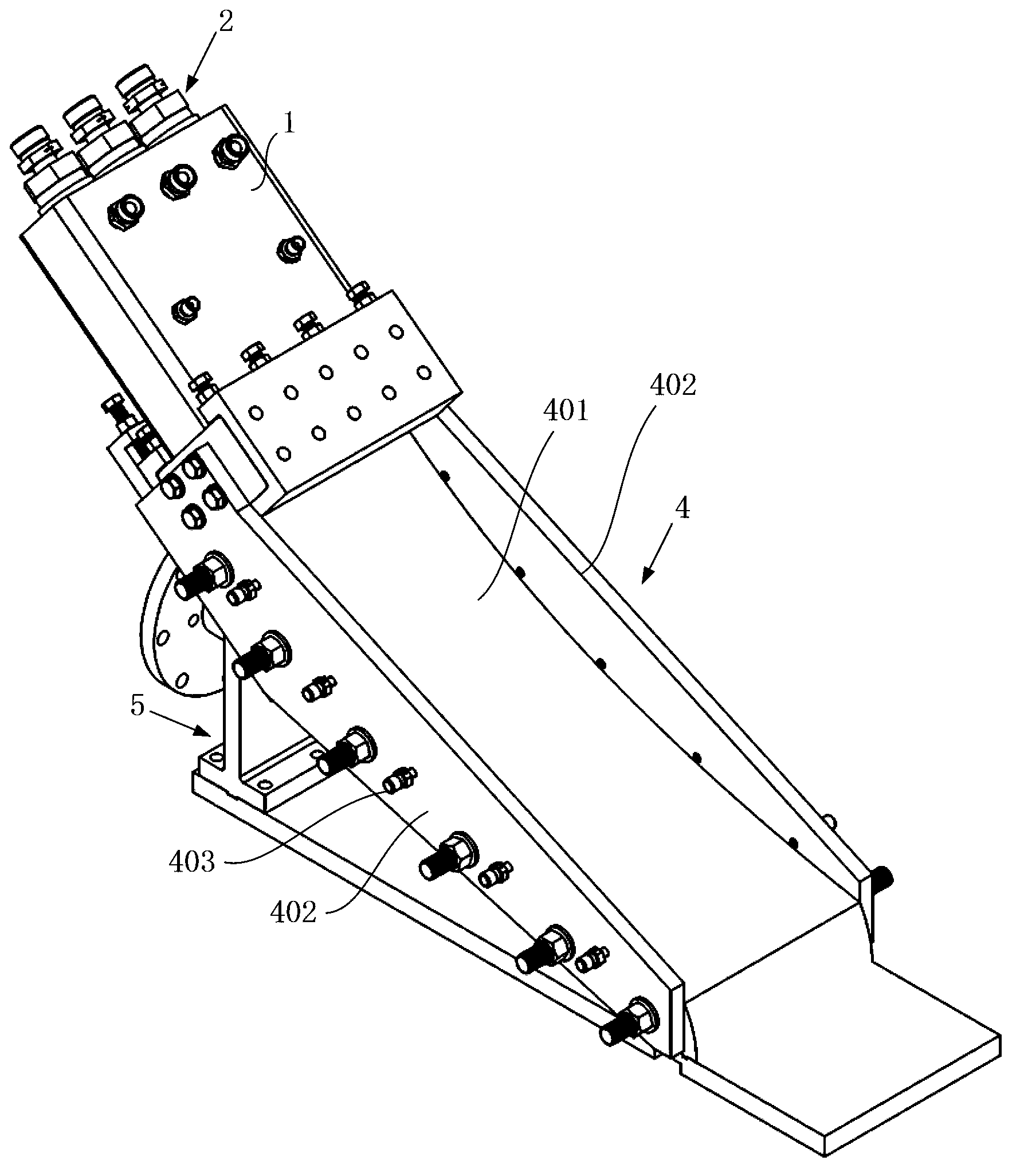

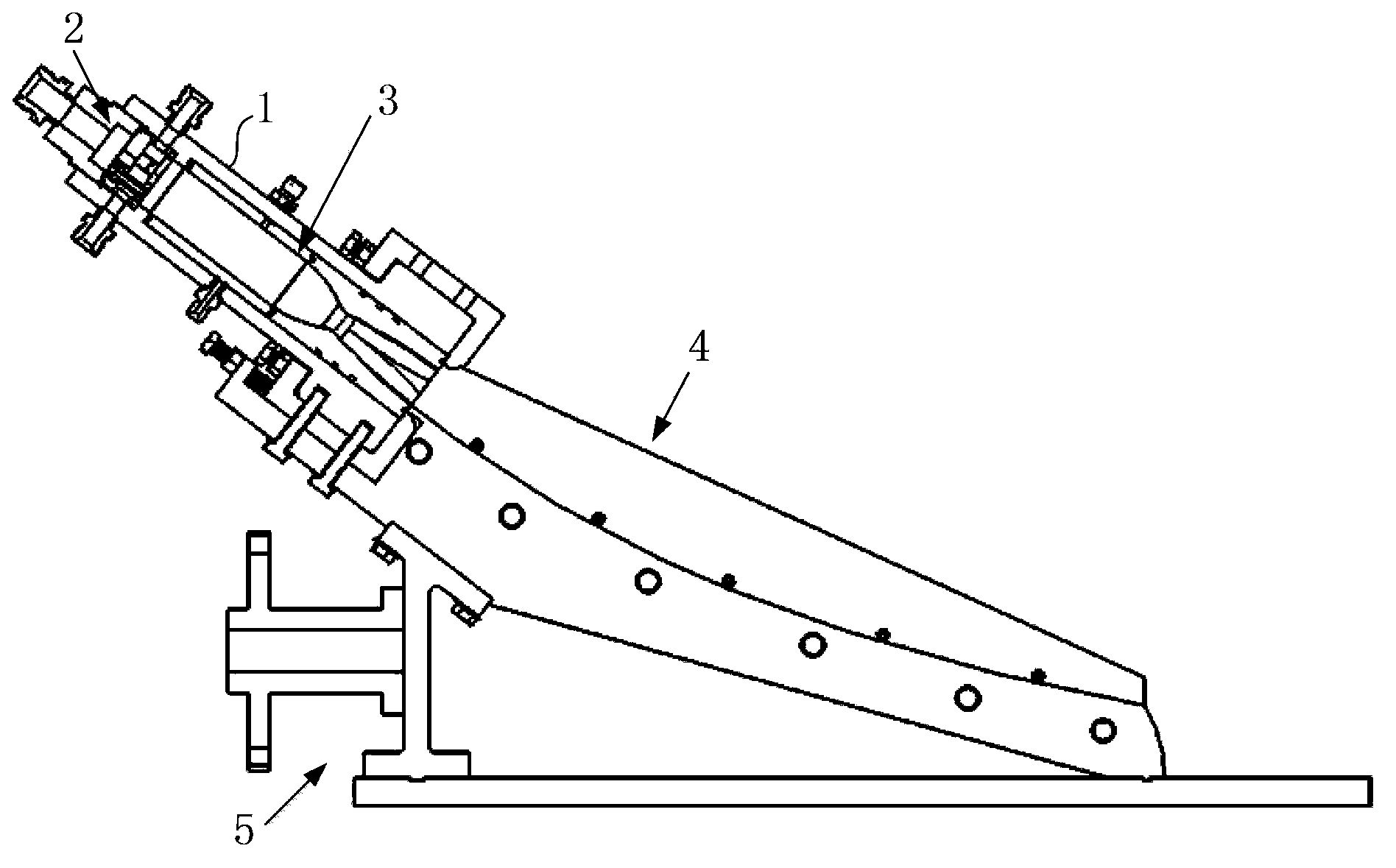

[0034] The present invention is a kind of modularized reusable multi-unit circular rotary square reduction ratio plug nozzle test device, such as figure 1 , figure 2 As shown, it includes a combustion chamber casing 1 , an injector assembly 2 , a combustion chamber assembly 3 , a plug cone assembly 4 and a support connection assembly 5 .

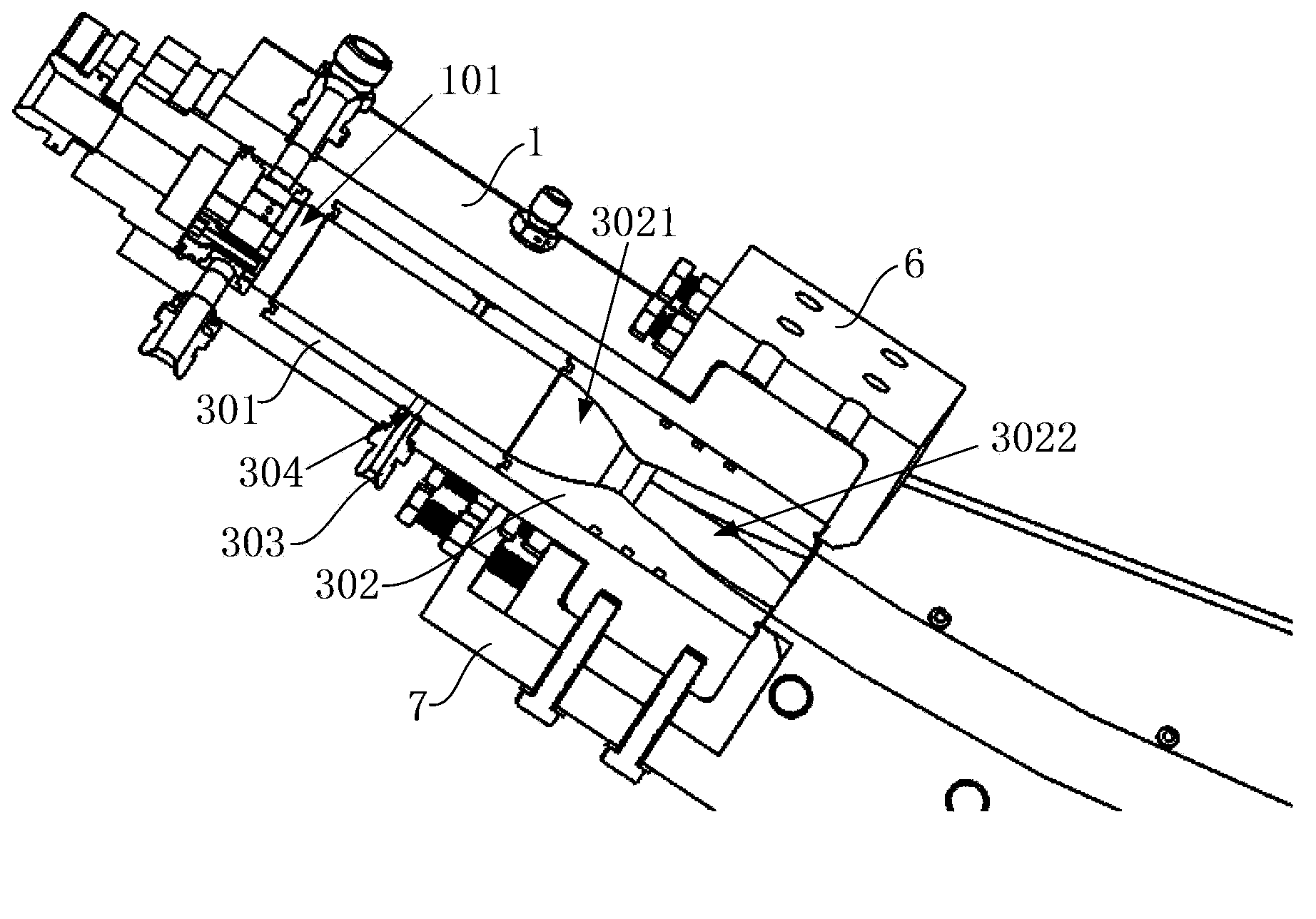

[0035] The combustion chamber housing 1 is processed by 1Cr18Ni9Ti material, and n cylindrical inner cavities 101 are arranged side by side, n>1, such as image 3 As shown, the specific number of inner chambers 101 is determined according to the outlet width of the circular inner nozzle 301 and the width of the plug cone 401, and the two ends of each inner chamber 101 pass through the front and rear ends of the combustion chamber housing 1; A set of injector assembly 2 and a set of combustion chamber assembly 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com