Plasma pressure sensor and plasma pressure sensing system

A pressure sensor, plasma technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve problems such as data errors, and achieve the effects of long service life, stable glow discharge, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

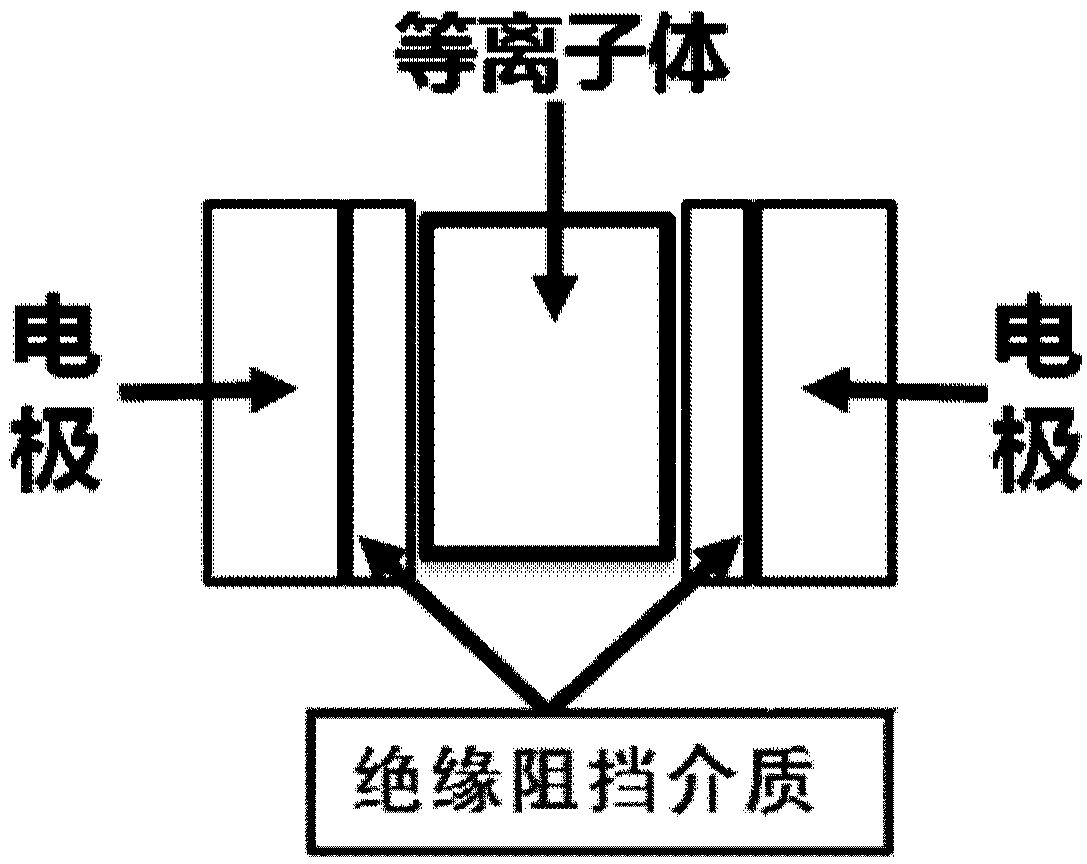

[0039] Based on the technical problem of electrode loss caused by cathode sputtering in the prior art, the present invention provides a plasma pressure sensor and system, including a discharge electrode, the discharge electrode includes two metal electrodes and two The insulating barrier medium on the surface, and the discharge electrode is used to generate plasma between the two insulating barrier mediums driven by an AC power source.

[0040] In order to make the purpose, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

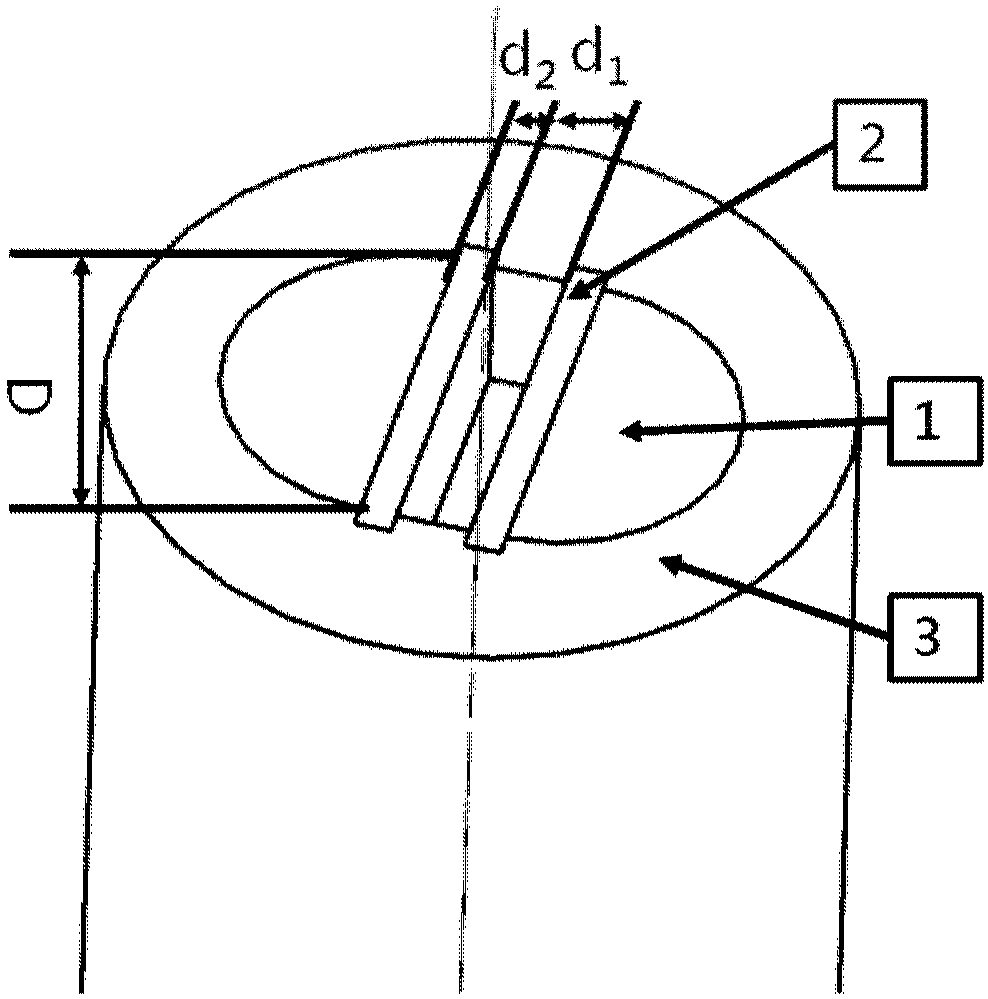

[0041] figure 1 It is a schematic diagram of the structure of the discharge electrode of the embodiment of the present invention, such as figure 1 As shown, the plasma pressure sensor includes a discharge electrode, and the discharge electrode includes two metal electrodes 1 and two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com