Interference spray test device for opposed piston engine

A technology of opposing pistons and testing devices, which is applied in the direction of internal combustion engine testing, etc., to achieve the effect of flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

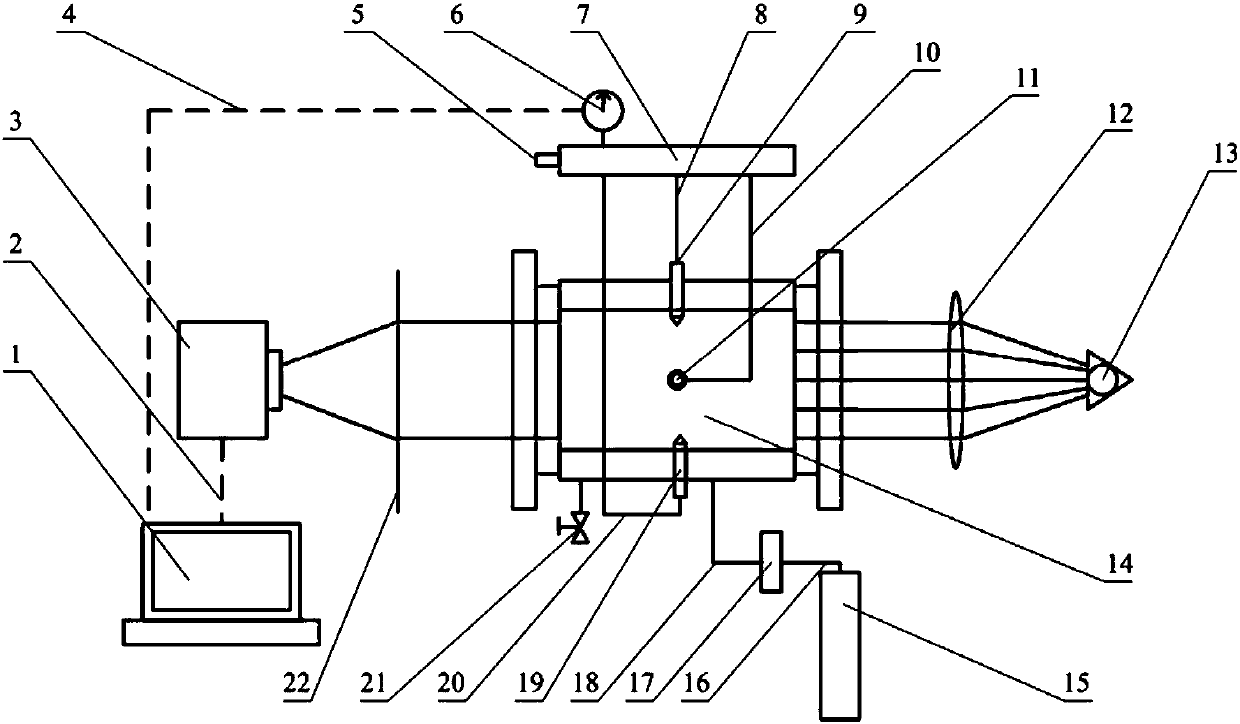

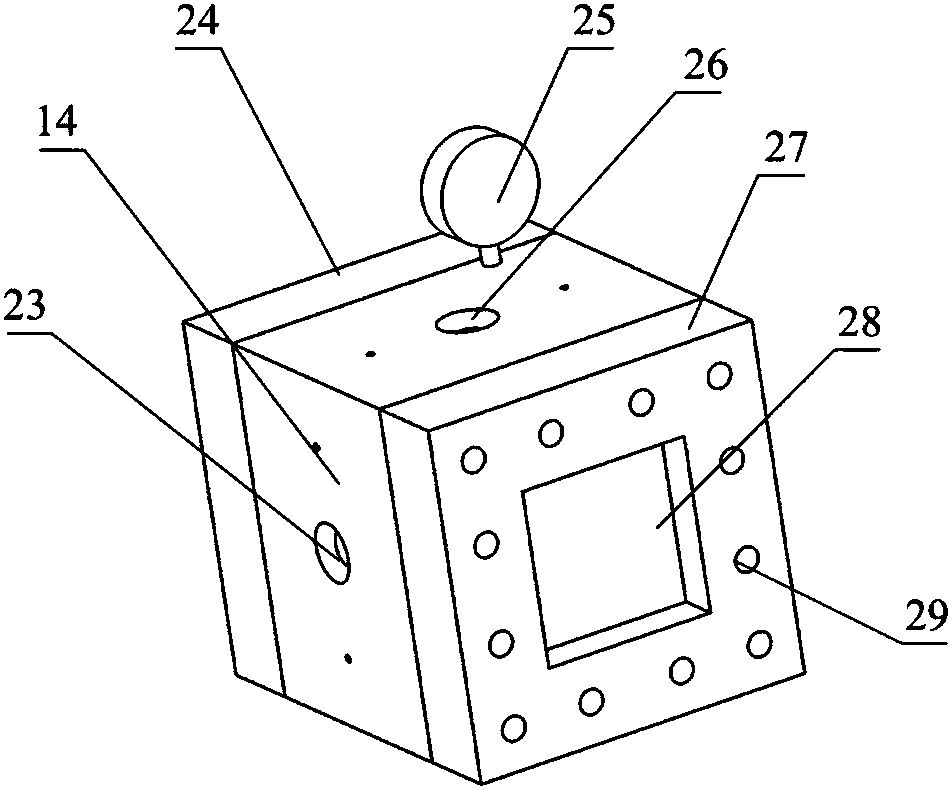

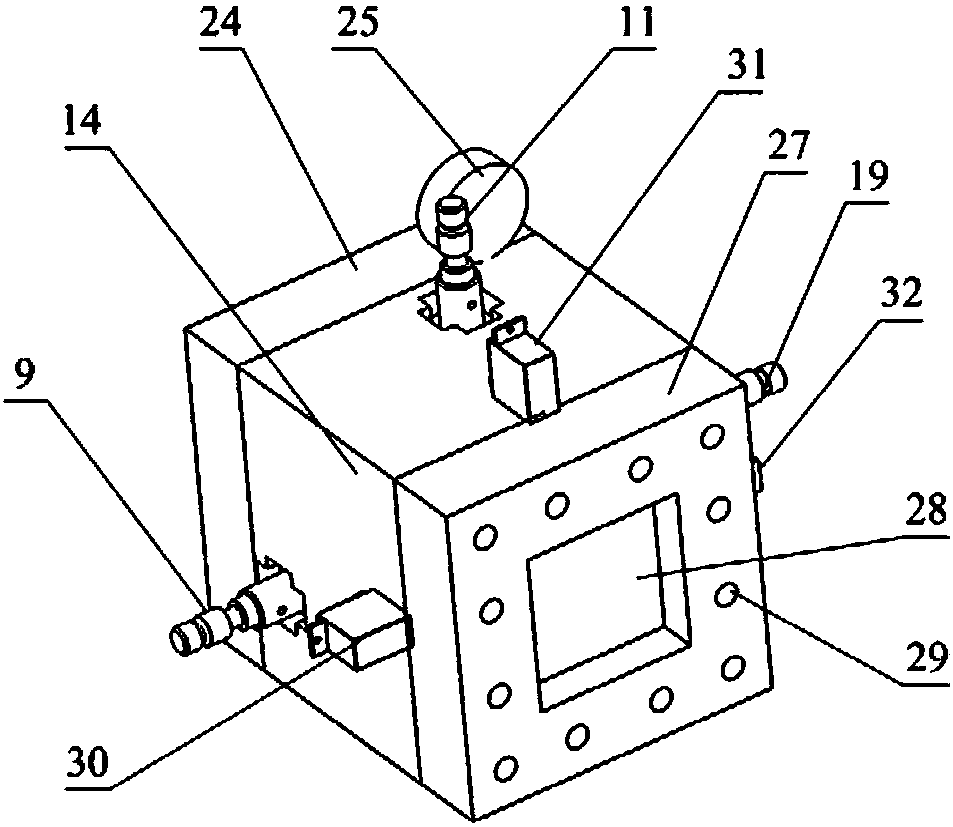

[0024] The invention provides an interference spray test device for an opposed-piston engine, comprising a constant volume bomb system, an intake and exhaust system, a fuel injection system, a high-speed photography system, a control and acquisition system, and the constant volume bomb system is used to simulate the position of the piston The internal situation in the combustion chamber at the inner dead point realizes the fuel injection collision atomization experiment; the intake and exhaust system provides the corresponding injection back pressure for the constant volume projectile body of the constant volume projectile system, and at the same time, the oil mist during the experiment Exhaust gas is discharged; the fuel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com