Cable performance testing device and cable performance testing method applying same

A technology of a testing device and a testing method, applied in the directions of measuring device, testing dielectric strength, measuring electricity, etc., can solve the problem of inability to accurately judge the damaged state of the inner conductor of the cable to be tested, difficult to evaluate the actual service life of the product, and the test results of the cable to be tested. Inaccuracy and other problems, to achieve the effect of reducing manual operations, improving test efficiency, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A cable performance testing method utilizing the above-mentioned cable performance testing device, the testing method comprises the following steps:

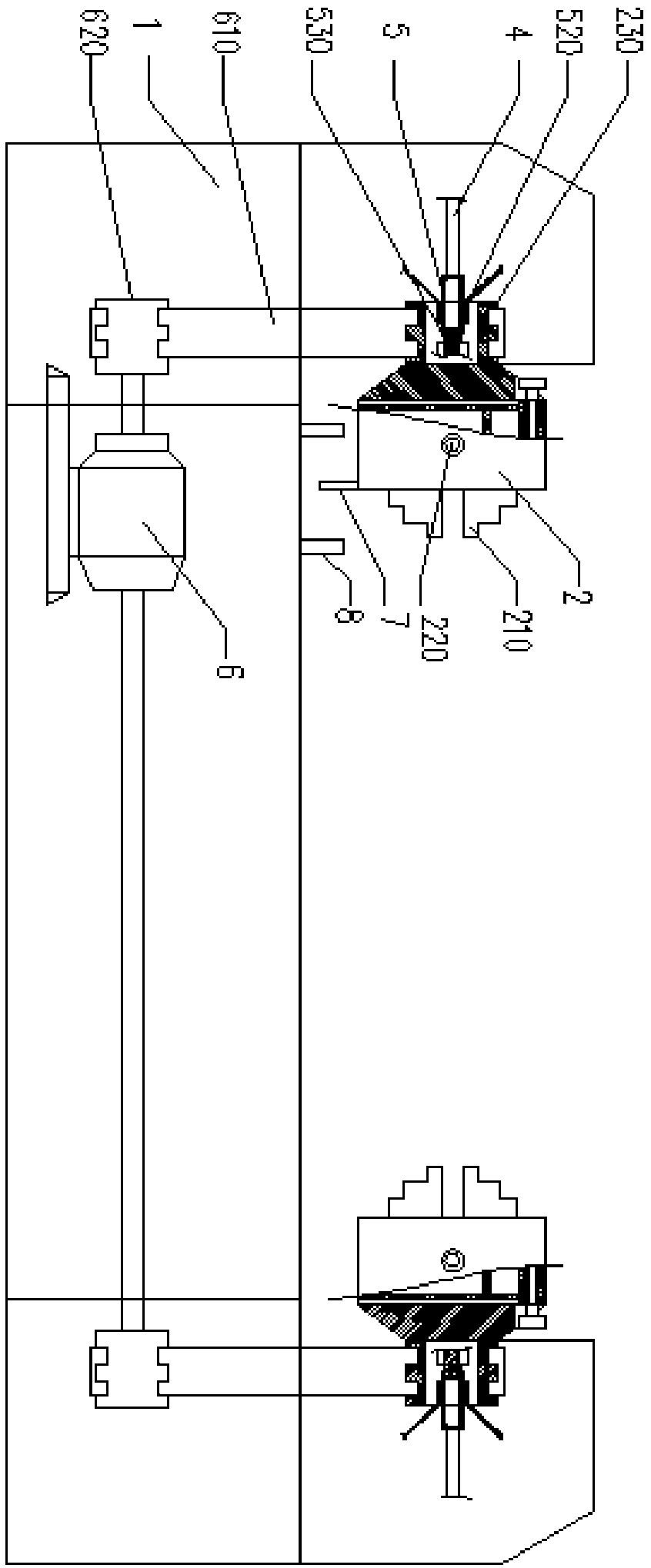

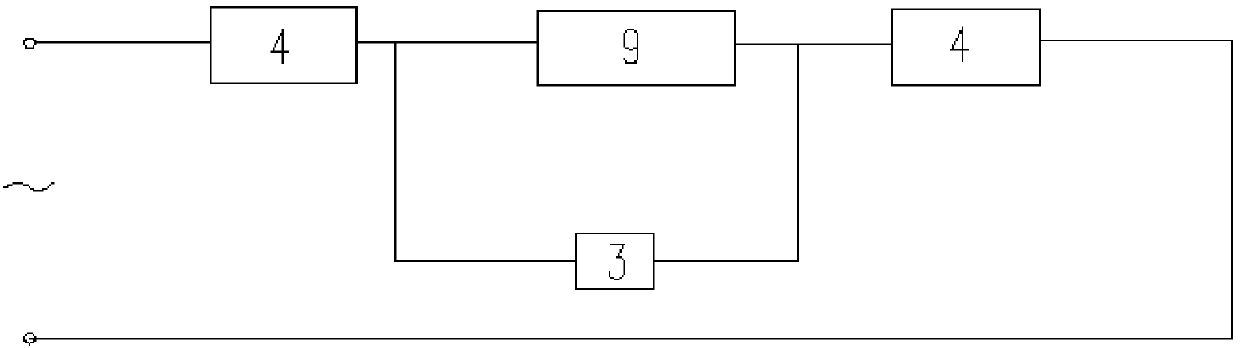

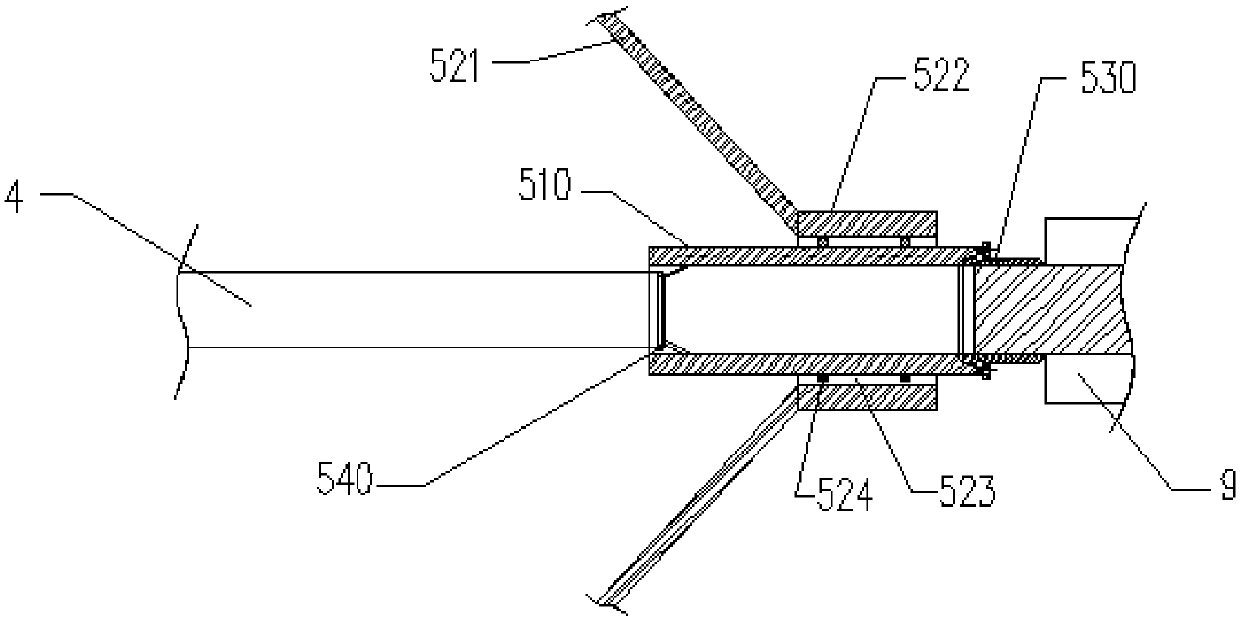

[0040]Step 1, peeling off the outer layer parts at both ends of the cable 9 to be tested, exposing the conductor parts, extending the conductor parts at both ends into the inside of the bundle tube 530 and tightening the bundle tube 530 by bolts 532;

[0041] Step 2, embed the front ends of the beam tubes 530 at both ends of the cable 9 to be tested in the hollow connecting shaft 510, and fasten them with bolts; respectively extend the two ends of the cable 9 to be tested into the mechanical chuck 210, so that the hollow connecting shaft 510 at both ends passes through the insulation The bracket 520 is fixed in the chuck rotating shaft 230;

[0042] Step 3, set the hollow connecting shaft 510 on the front end of the high-voltage lead-out rod 4, and move the front end of the conductive attachment 540 so that it elastically...

Embodiment 2

[0048] A cable performance testing method using the above-mentioned cable performance testing device, the testing method comprises the following steps:

[0049] Step 1, peeling off the outer layer parts at both ends of the cable 9 to be tested, exposing the conductor parts, extending the conductor parts at both ends into the inside of the bundle tube 530 and tightening the bundle tube 530 by bolts 532;

[0050] Step 2, embed the front ends of the beam tubes 530 at both ends of the cable 9 to be tested in the hollow connecting shaft 510, and fasten them with bolts; respectively extend the two ends of the cable 9 to be tested into the mechanical chuck 210, so that the hollow connecting shaft 510 at both ends passes through the insulation The bracket 520 is fixed in the chuck rotating shaft 230;

[0051] Step 3, set the hollow connecting shaft 510 on the front end of the high-voltage lead-out rod 4, and move the front end of the conductive attachment 540 so that it elastically to...

Embodiment 3

[0057] A cable performance testing method using the above-mentioned cable performance testing device, the testing method comprises the following steps:

[0058] Step 1, peeling off the outer layer parts at both ends of the cable 9 to be tested, exposing the conductor parts, extending the conductor parts at both ends into the inside of the bundle tube 530 and tightening the bundle tube 530 by bolts 532;

[0059] Step 2, embed the front ends of the beam tubes 530 at both ends of the cable 9 to be tested in the hollow connecting shaft 510, and fasten them with bolts; respectively extend the two ends of the cable 9 to be tested into the mechanical chuck 210, so that the hollow connecting shaft 510 at both ends passes through the insulation The bracket 520 is fixed in the chuck rotating shaft 230;

[0060] Step 3, set the hollow connecting shaft 510 on the front end of the high-voltage lead-out rod 4, and move the front end of the conductive attachment 540 so that it elastically to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com