Double self-lubricating bearing motor

A technology of self-lubricating bearings and shaft tubes, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of failure to form normal oil film, damage to the surface of the mandrel, and aggravated wear, so as to reduce up and down movement and left and right shaking , reduce left and right swing and up and down movement, reduce the effect of heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

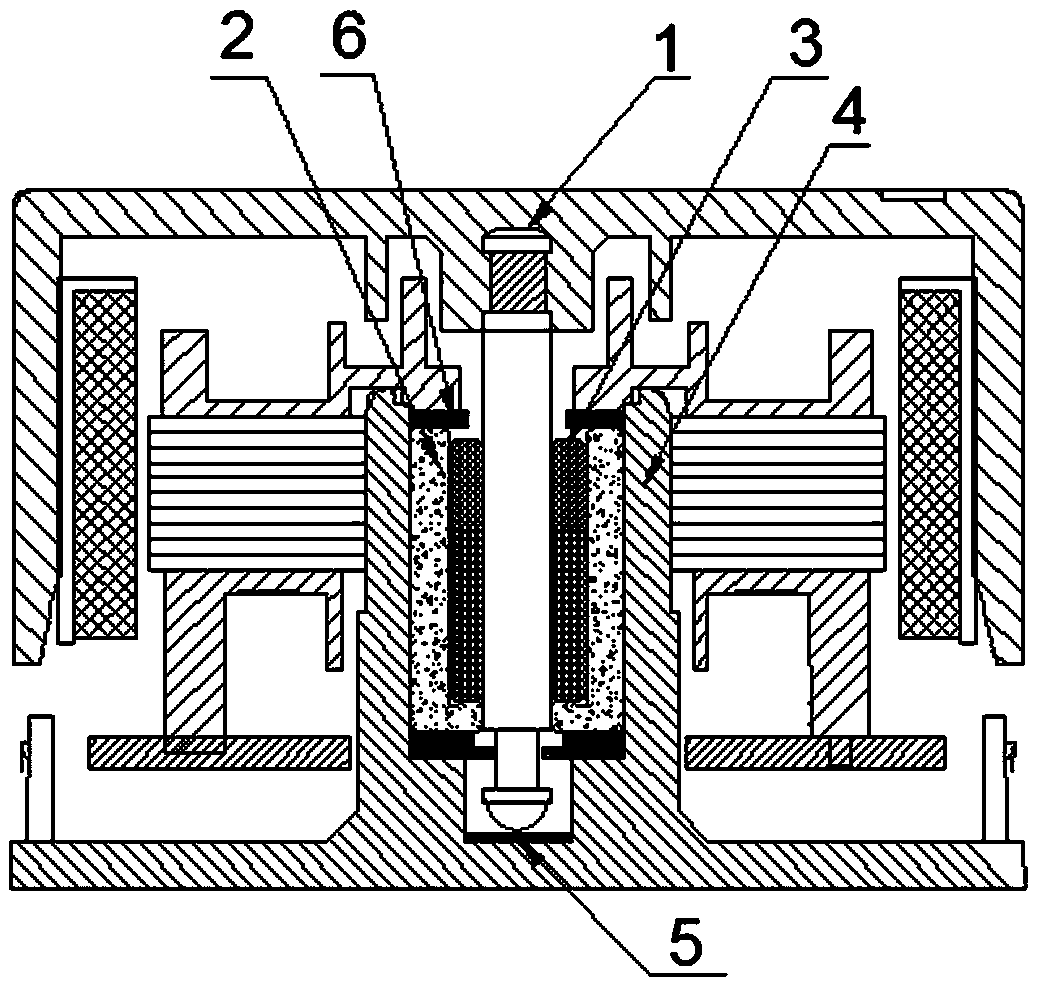

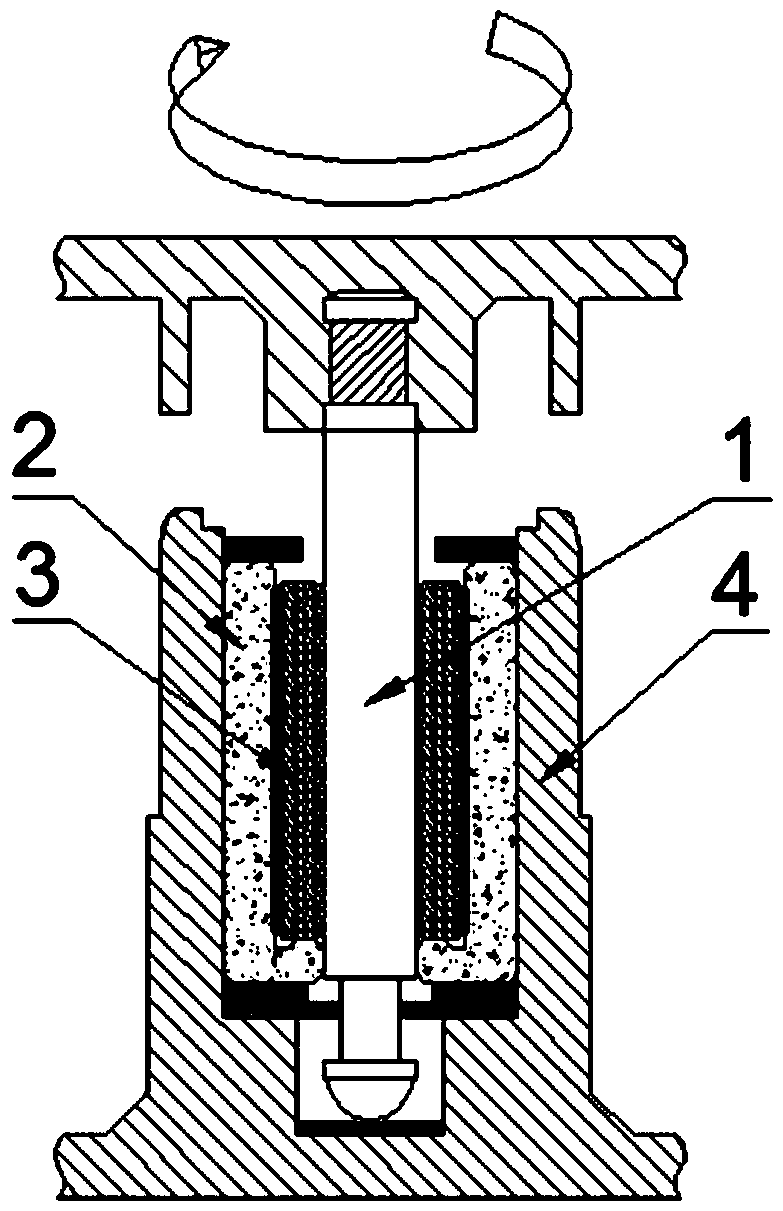

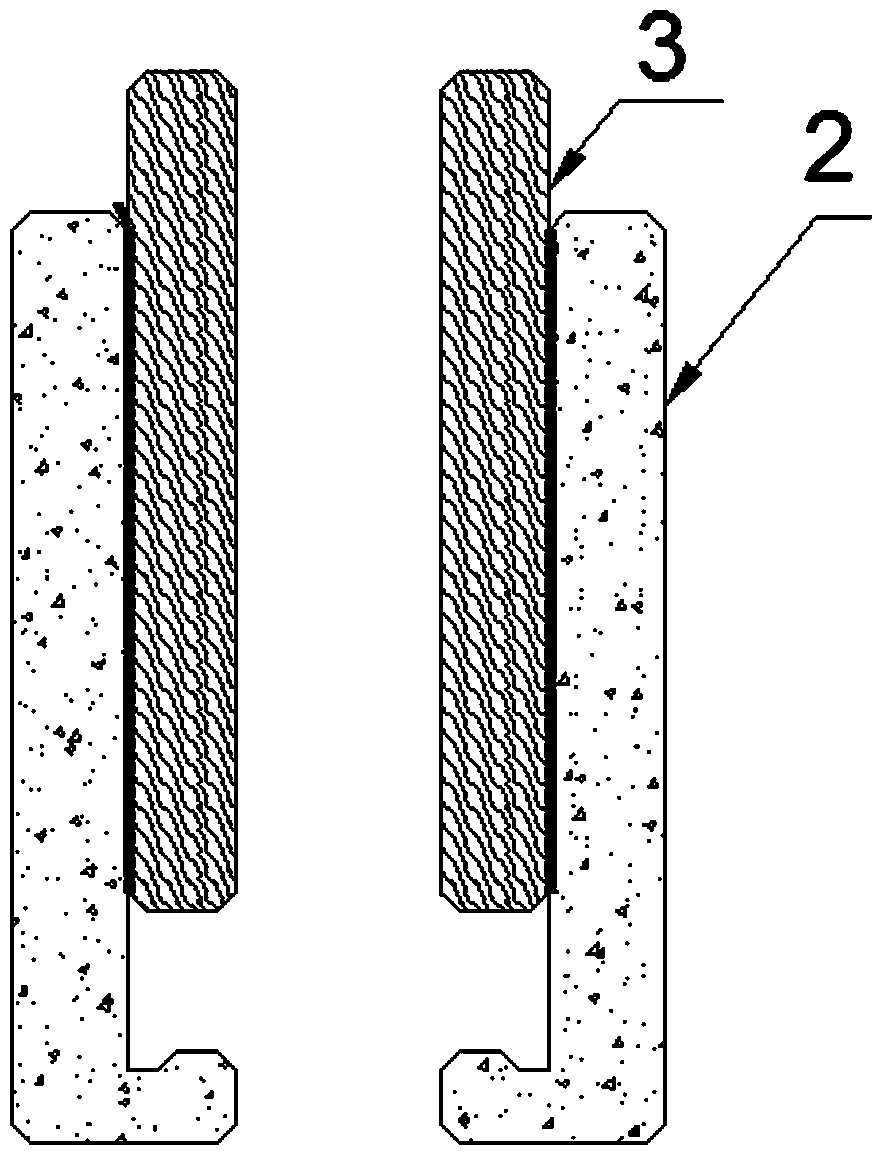

[0018] see Figure 1-4 , a double self-lubricating bearing motor, including a stator and a rotor, a shaft tube 4 is sleeved inside the stator, a mandrel is provided on the rotor, and a first self-lubricating bearing 2 and a second self-lubricating bearing 2 are inserted inside the shaft tube 4 Self-lubricating bearing 3, the first self-lubricating bearing 2 and the shaft tube 4 are in a tight fit. After assembly, the first self-lubricating bearing 2 is fixed in the shaft tube 4 and cannot move freely relative to each other. The second self-lubricating bearing 3 is slid into the first self-lubricating bearing In the inner hole of the first self-lubricating bearing 2, the inner hole of the second self-lubricating bearing 3 is provided with a mandrel 1, and the mandrel 1 is inserted through the inner hole of the second self-lubricating bearing 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com