Novel motor controller device integration structure

A motor controller, integrated technology, applied in the direction of motor control, electrical components, control systems, etc., can solve the problems of difficult assembly pre-installation, high manufacturing yield, difficult to guarantee, etc., to improve the space utilization of the whole machine , Improve manufacturability and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

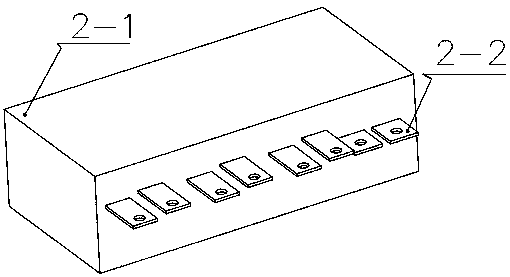

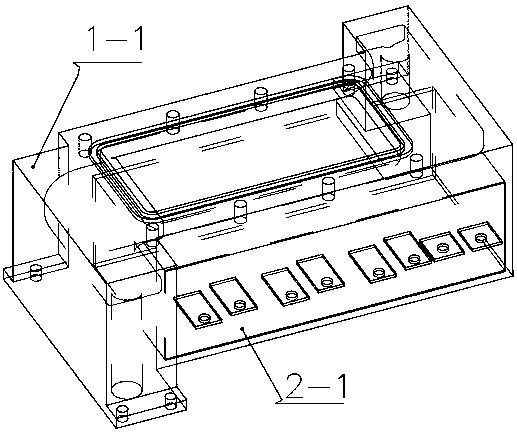

[0019] This embodiment provides a new motor controller IGBT cooling water channel and capacitor integrated structure. The integrated structure is designed with a specific shell, internally designed with a water channel structure and a capacitor cavity, and the water channel structure can simultaneously dissipate heat for the IGBT and the capacitor. It can effectively and quickly reduce the temperature of the capacitor and improve the life and reliability of the capacitor. The capacitor core and the busbar copper bar are sealed with epoxy resin glue in the capacitor cavity. Through specific tooling, the positioning of the capacitor core and the busbar copper bar is guaranteed. with fixed.

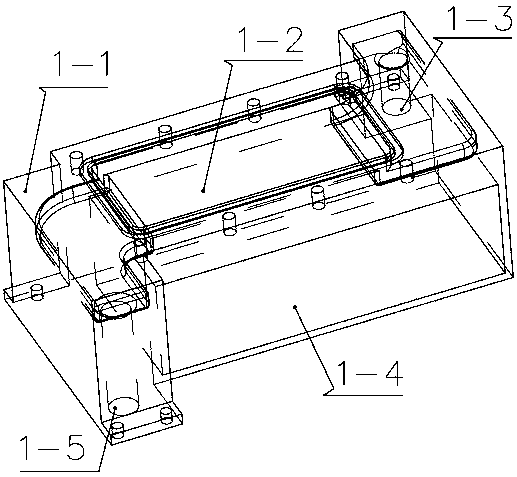

[0020] Such as figure 1 As shown, the integrated structure of the new motor controller device described in the present invention includes an integrated structural shell 1-1 of aluminum alloy material, and the integrated structural shell 1-1 is provided with a water channel heat dissipation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com