Polishing composition

A technology of composition and abrasive grains, which is applied to polishing compositions containing abrasives, grinding machine tools, grinding devices, etc., can solve the problems of easy sedimentation of abrasive grains, uneven grinding composition, grinding damage, etc., which is not easy to achieve Sedimentation, easy redispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

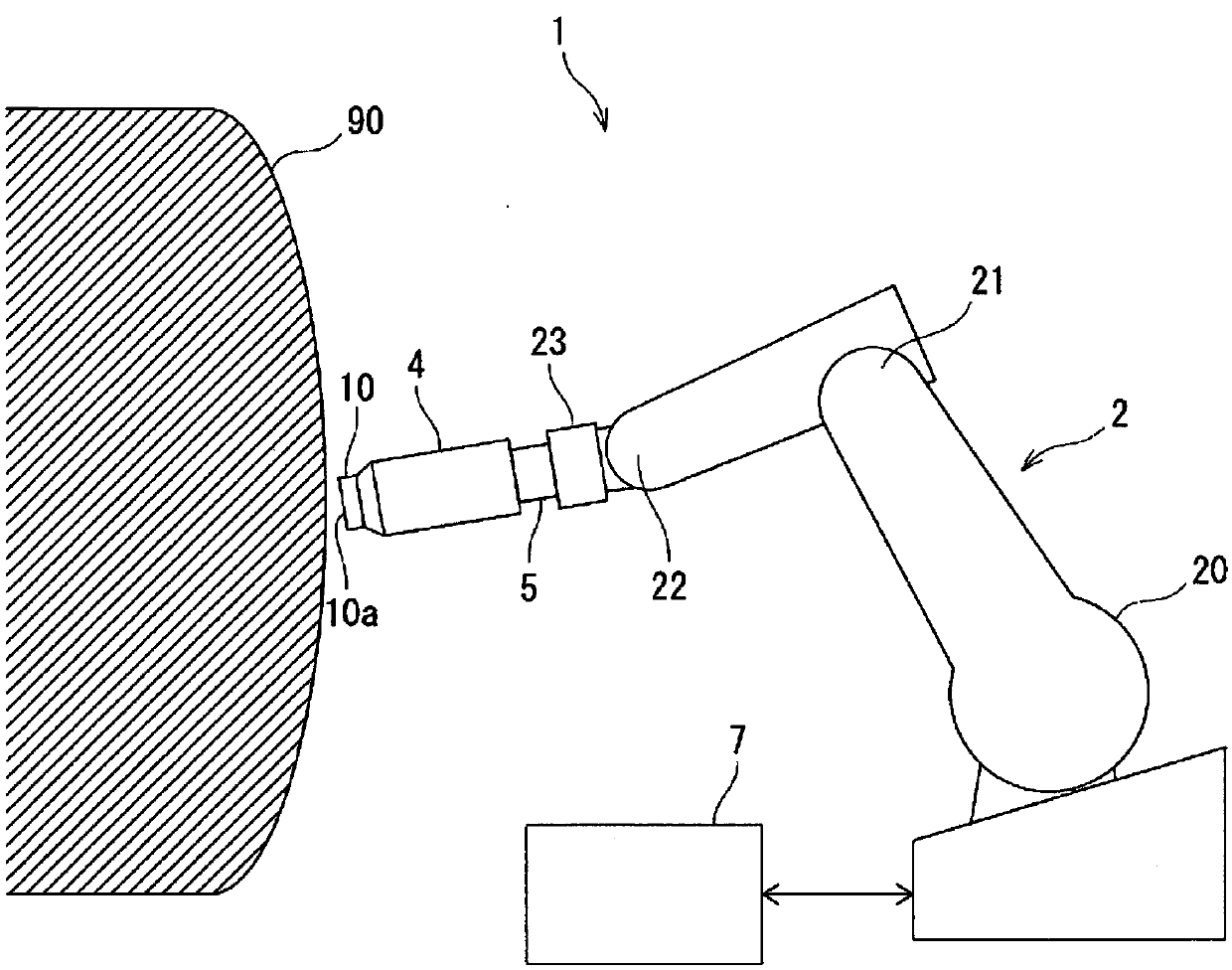

Image

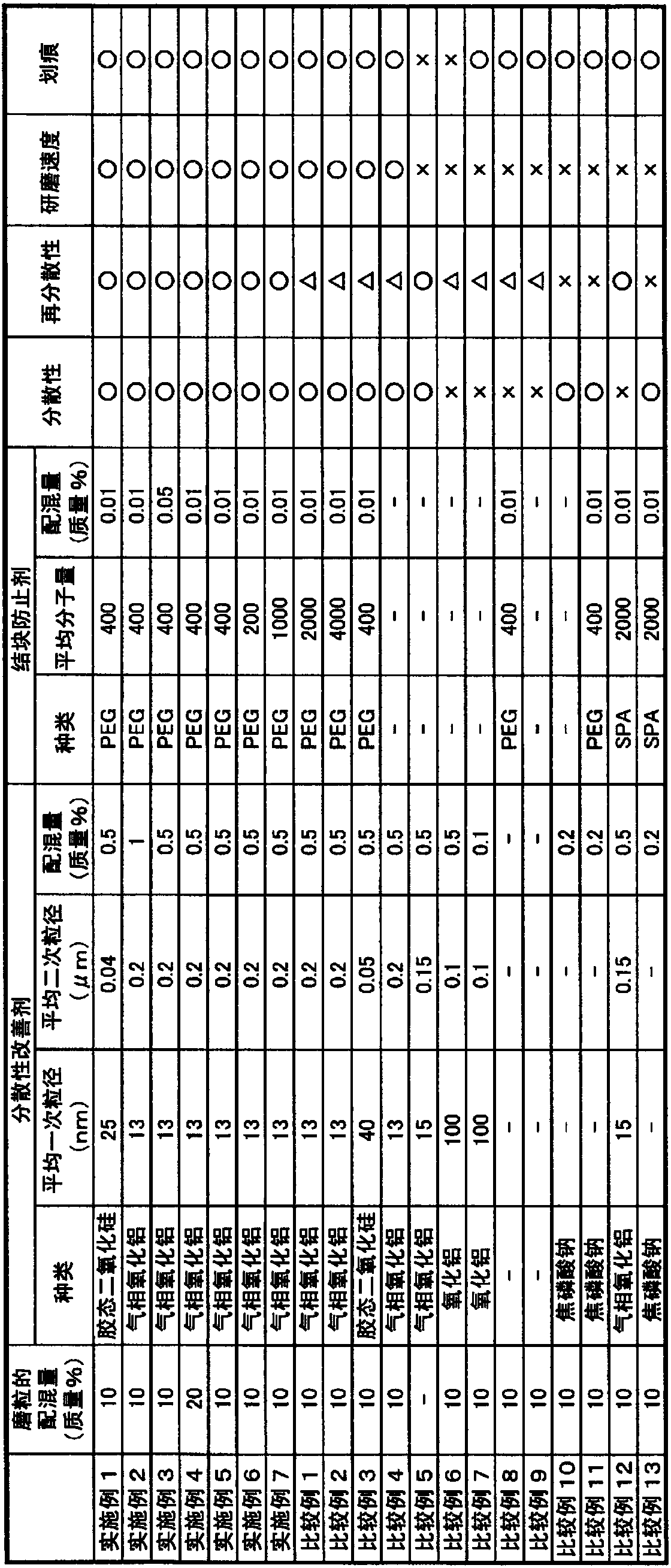

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in detail. The polishing composition of this embodiment contains abrasive grains, a liquid medium, metal oxide particles, and a water-soluble polymer. In addition, the average primary particle diameter of the metal oxide particles is 1 / 10 or less of the average primary particle diameter of the abrasive grains, and the weight average molecular weight of the water-soluble polymer is 200 to 1000.

[0019] In the polishing composition having such a constitution, the abrasive grains are less prone to sedimentation, and the sedimented and aggregated abrasive grains are easily redispersed. Therefore, since the polishing composition is not easy to become uneven, and there are few aggregated abrasive grains, if the polishing object is polished using the polishing composition of the present embodiment, the polishing object can be polished at a high polishing rate. Grinding, and grinding damage is not easy to occur on the pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com