Aquatic-product apparatus

An equipment and aquatic technology, applied in the field of deep processing of shellfish and seafood, can solve the problems of low production efficiency, high labor intensity and small labor volume, and achieve the effect of low cost, low labor intensity and improved product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

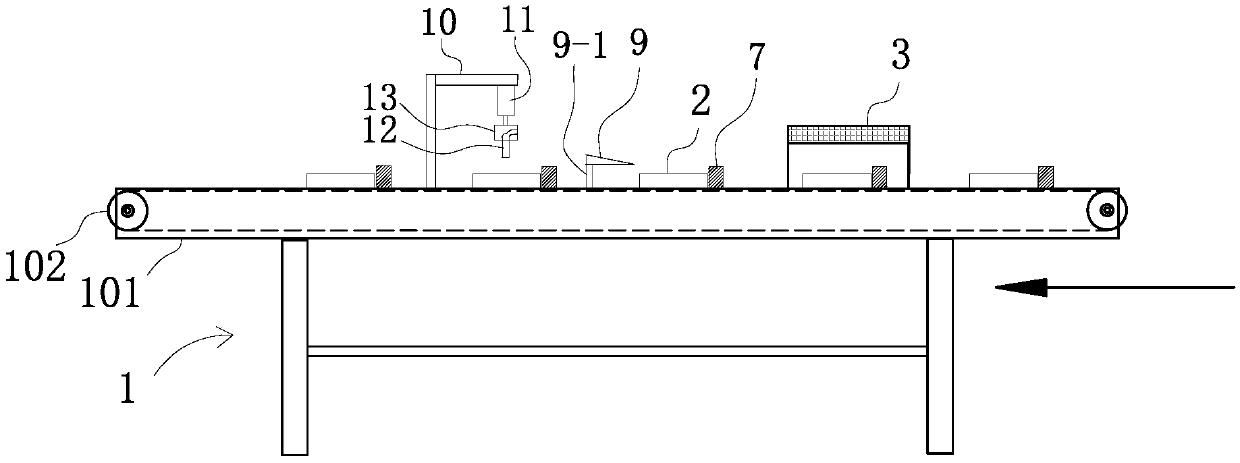

[0059] Such as Figure 1-7 As shown, the aquatic equipment includes a conveying device 1, a heating device 3, an automatic shell removing device and an automatic shellfish picking device.

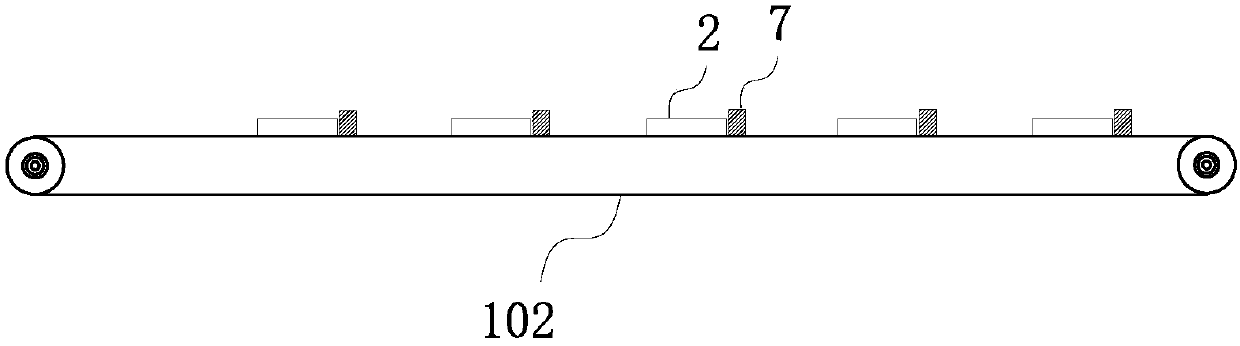

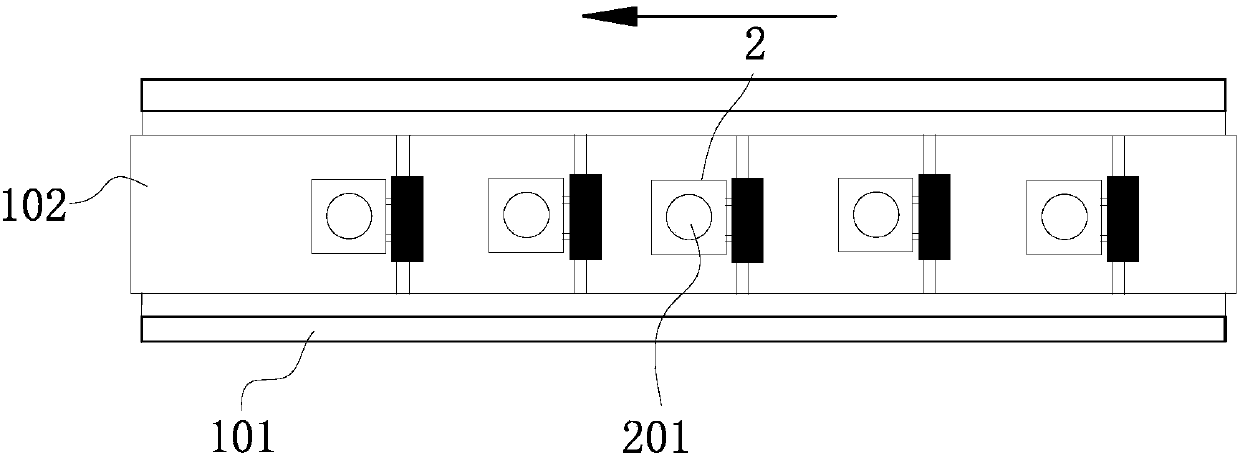

[0060] The conveying device 1 includes a frame 101 on which a conveyor belt 102 is connected, and several scallop seats 2 are connected on the conveyor belt 102 . The scallop seat 2 includes a flat plate, which is provided with a round hole 201 for placing scallops. The conveying device 1 is preferably a chain conveyor. For the structure of the scallop seat 2, grooves are opened on the flat plate, and scallop products can also be placed.

[0061] figure 1 and image 3 and Figure 4 The arrow in represents the direction in which the conveyor belt 102 travels, that is, the direction in which the scallop holder 2 moves. According to the moving direction of the scallop seat 2, the heating device 3, the upper shell automatic removal device, and the shellfish meat automatic picking device a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap